A Guide to Construction Waste Disposal in the UK

A Guide to Construction Waste Disposal in the UK

Proper construction waste disposal is simply the process of legally and responsibly handling all the leftover materials from a building, renovation, or demolition job. It means sorting out the rubble, wood, and metal, making sure a licensed carrier collects it, and trying to recycle as much as possible to keep it out of landfill. It’s not just a nice idea for the environment—it’s a strict legal requirement.

Why Managing Construction Waste Matters

Think of a construction site like a huge kitchen. Just as a chef ends up with peelings, packaging, and offcuts, a building site churns out bits of timber, broken bricks, and surplus materials. Proper waste disposal is the clean-up plan for all those leftovers, making sure they don't cause a mess for the environment or land you in legal trouble. This isn't just about keeping the site tidy; it's a core part of modern, professional project management.

The sheer scale of the problem is massive. The UK's construction industry is the single biggest producer of waste in the country, responsible for around 62% of the nation's total waste every single year. That adds up to roughly 100 million tonnes of everything from concrete and bricks to metals and timber.

A Legal and Environmental Must-Do

Getting this wrong can have serious knock-on effects. Disposing of waste incorrectly can lead to eye-watering fines, stop-work orders, and a black mark against your professional reputation that's hard to shift. The rules are there for a very good reason: to protect our green spaces, save valuable resources, and clamp down on illegal fly-tipping.

Every single business and person involved in a construction project has a legal ‘Duty of Care’ over the waste they create. This isn’t just a bit of jargon—it means your responsibility doesn't stop when the skip lorry drives away. It follows that waste all the way until it’s been properly recycled or disposed of.

The Upside of a Proactive Approach

Beyond just dodging penalties, having a solid waste management plan from day one has some real benefits. It makes the whole site run smoother, improves safety by keeping walkways clear, and can even trim your project costs through smarter use of materials and maximising recycling rebates.

If you're curious about how things are done elsewhere, this guide to construction waste disposal in the UAE offers a fascinating look at different rules and systems. For now, though, this guide will walk you through everything you need to know to handle your site waste like a pro, right here in the UK.

Understanding Your Legal Duty of Care for Waste

The moment your project creates waste – even a single bag of rubble or a pile of offcuts – the law puts a very specific responsibility on your shoulders. This is the Duty of Care, a legal requirement that doesn’t just end when your waste is collected. Think of it as an unbroken chain of responsibility that you have to manage from your site right through to final disposal.

Imagine you’re sending a valuable, fragile package. You wouldn't just hand it to the first person walking by. You'd pick a reputable courier, get a tracking number, and make sure it arrives safely. Your construction waste needs exactly the same level of care. You are legally required to ensure it is handled correctly at every single stage.

Getting this wrong can lead to serious penalties, including unlimited fines. And pleading ignorance won't get you off the hook. If you hire an unlicensed carrier and they fly-tip your waste, you’re the one who could be held liable. That's why getting to grips with this duty is absolutely fundamental to any project, big or small.

The Role of Waste Transfer Notes

So, how do you actually prove you've followed the rules and met your Duty of Care? The key piece of paper is the Waste Transfer Note (WTN). This isn't just a simple receipt; it's a legally binding document that tracks the transfer of waste from you to a licensed carrier. Without a correctly filled-out WTN for every single load that leaves your site, you have zero proof of compliant disposal.

A valid WTN is your legal shield. It acts as a paper trail that the Environment Agency can follow, and it must contain specific details to be compliant.

A complete Waste Transfer Note must include:

- A detailed description of the waste: You need to be specific here. List the types of materials and use the correct European Waste Catalogue (EWC) code.

- Information about both parties: This means your name and address (as the waste producer) and the details of the company collecting it.

- The carrier’s licence details: You must check and record the waste carrier's registration number to prove they are authorised by the Environment Agency.

- The transfer location and date: The document needs to state exactly where and when the waste was handed over.

You have to keep copies of all your WTNs for a minimum of two years, as you could be asked to produce them at any time to prove you’re compliant. For a more detailed breakdown, our guide explains precisely what is a waste transfer note and why it's so vital for your project's legal safety.

Dealing with Hazardous Materials

The Duty of Care gets even stricter when you’re dealing with hazardous waste. These are the materials that pose a real threat to human health or the environment, and they must be handled and disposed of through specialised routes.

In construction, the most common hazardous material is asbestos. But other items like solvents, paints, oils, and some types of insulation also fall into this category. You cannot mix these materials with your general site waste.

For these items, you have to use a specialist, licensed hazardous waste carrier and fill out a Consignment Note, which is a more detailed version of a WTN. The rules for handling materials like asbestos are incredibly strict, and failing to comply can even result in imprisonment. The process involves secure containment, clear labelling, and transport to a specific hazardous waste facility.

Ultimately, your legal duties are part of a much wider framework of site management. To build on your knowledge of legal compliance, it's also worth reviewing resources on understanding broader workplace safety procedures, as this helps create a safer, more compliant environment all round. Taking these responsibilities seriously doesn’t just protect you from legal trouble – it protects the community and our environment from harm.

Choosing the Right Disposal Method for Your Project

Figuring out the best way to get rid of your construction waste can feel like a bit of a puzzle, but it really boils down to one thing: matching the solution to your job. Think of it like picking the right tool. You wouldn't use a sledgehammer to hang a picture, and you definitely wouldn't try to clear a demolition site with the boot of your car.

This is your practical guide to making that choice. We'll walk through the most common options, using real-world scenarios to show you where each one really shines. Whether you're a homeowner finally tackling that garden makeover or a site manager on a big commercial build, getting this right is your first step to a smooth, cost-effective project.

Comparing Construction Waste Disposal Options

To make things clearer, let's put the main players side-by-side. Each method has its own strengths, so the "best" one truly depends on the scale of your project, the type of waste you have, and how much space you're working with.

| Disposal Method | Ideal For | Typical Capacity | Key Advantage |

|---|---|---|---|

| Skip Hire | Small-to-medium domestic projects, garden clearances, renovations. | 4 to 8 cubic yards | Simple, convenient, and great for mixed waste over a set hire period. |

| Roll-On Roll-Off (RoRo) | Large construction sites, commercial demolitions, major clear-outs. | 20 to 40 cubic yards | Massive volume for bulky waste, reducing the number of collections. |

| Grab Lorry | Projects with heavy, inert waste (soil, rubble) and limited space. | Approx. 16 tonnes | Super-fast collection without needing a permit or manual loading. |

| Licensed Tip | Small, single loads or tradespeople accumulating waste during the day. | Varies by vehicle | Total control over timing and often cost-effective for smaller amounts. |

Understanding these basic differences is key. A skip might be perfect for your bathroom refit, but for a major groundwork project, a grab lorry will save you an incredible amount of time and effort.

Skips: Perfect for Small to Medium Projects

For most home renovations, small extensions, or garden clear-ups, the classic builder's skip is the undisputed champion. Its beauty is in its simplicity: we drop it off where you want it, you fill it up over a few days, and then we take it away. Job done.

Skips come in different sizes, measured in cubic yards. A little 4-yarder is spot-on for a bathroom refit, while the bigger 8-yard builder's skip will easily handle an old kitchen or a serious landscaping job. They're built to take a mix of non-hazardous stuff like wood, soil, rubble, and old fittings.

Just remember the practicalities. You need a driveway or private land to put it on. If it has to go on the road, you'll need a permit from the council, which means extra cost and a bit of admin. And don't be tempted to overfill it—they have a strict level-load limit for safety.

Roll-On Roll-Off Bins for Major Waste Volumes

When a standard skip just won't cut it, you need to bring in the big guns: the Roll-On Roll-Off (RoRo) container. These are the huge bins you see on major construction sites, built for projects that generate a mountain of waste—think commercial demolitions, new builds, or factory clear-outs.

RoRos have enormous capacities, usually from 20 to 40 cubic yards, making them perfect for bulky but lighter materials like timber, metal, and general site debris. Their biggest selling point is sheer size, which means fewer collections and often a lower cost per yard on really big jobs.

The main thing to consider with a RoRo is access. They're delivered by massive lorries that need plenty of room to turn, unload, and collect the bin. This rules them out for tight residential streets or sites with narrow gates.

Grab Lorry Hire for Access and Speed

So, what happens when you’ve got piles of heavy waste like soil, concrete, or rubble, but no space for a skip? This is where the grab lorry becomes your best friend. These trucks have a hydraulic crane with a "grab" bucket, letting them reach over fences, walls, and other obstacles to pick up waste directly from the ground.

The benefits here are speed and convenience. You don’t need a permit, and the waste can be gone in as little as 20-30 minutes, getting your site clear almost instantly. It’s the perfect solution for excavation jobs, driveway rip-outs, or any scenario where you have waste piled up and ready to go. You can find out more in our detailed guide to grab lorry waste removal.

A single grab lorry can often shift the equivalent of two large builder’s skips worth of heavy waste. The ability to just "grab and go" saves a massive amount of time and back-breaking labour compared to loading a skip with wheelbarrows.

Using Licensed Waste Transfer Stations

If you only have a small amount of waste, or you're a tradesperson who gathers bits and pieces throughout the day, taking it directly to a licensed waste transfer station (the 'tip') can be a good option. It gives you full control over when you dispose of your waste and can be cheap for one-off loads.

The catch is that you need to be compliant. You must check the facility is licensed to take commercial waste, and you must hold a valid Waste Carrier Licence if you're transporting waste from your business. And, of course, you'll need your Waste Transfer Note paperwork sorted.

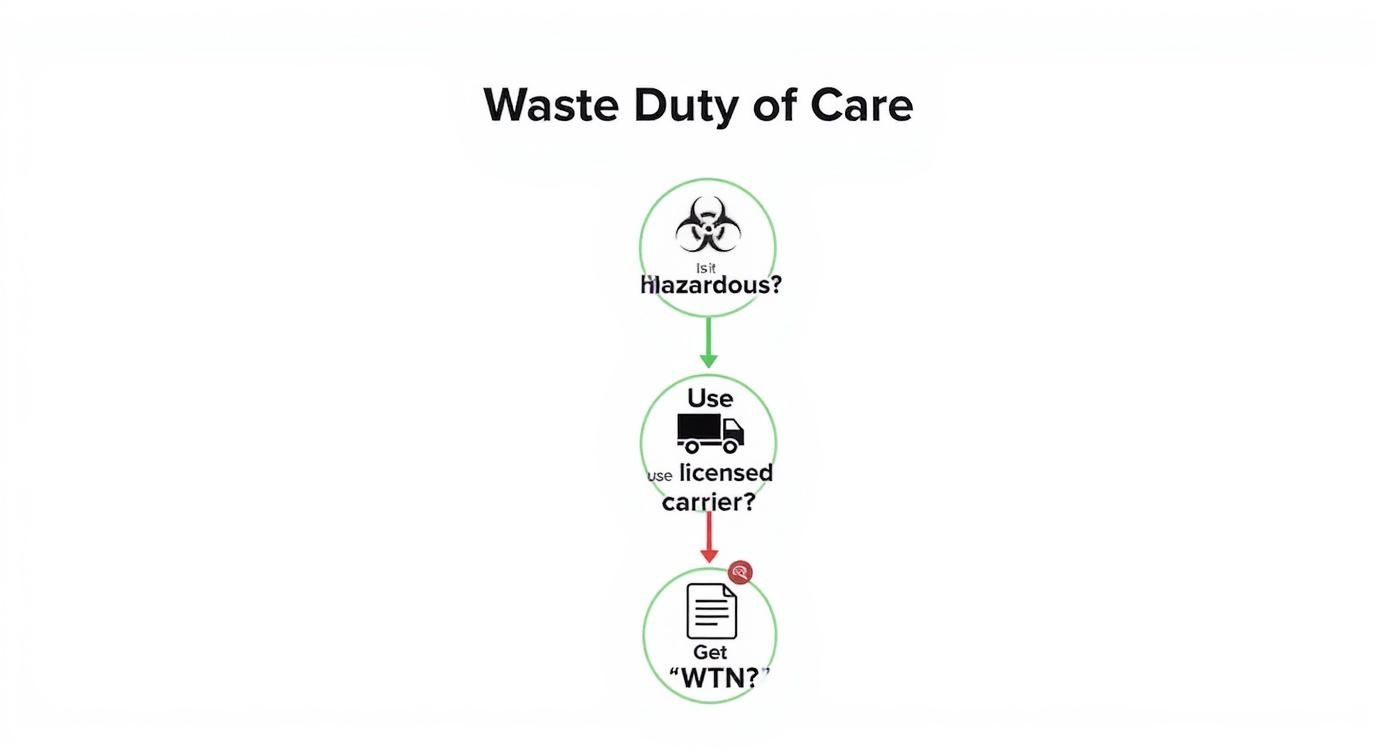

This whole decision-making process is underpinned by your legal Duty of Care. This flowchart breaks down the essential steps you have to take to stay on the right side of the law.

As you can see, every step—from checking for hazardous materials to getting that Waste Transfer Note—is a crucial part of fulfilling your responsibilities.

How to Budget for Waste Disposal Costs

Forgetting to budget for waste management can blow a serious hole in your project's bottom line. It's a classic rookie mistake. Unexpected disposal fees are one of the most common reasons projects creep over budget, but you can get a surprisingly accurate handle on the costs with a bit of forward planning. The final price you pay isn't just about the size of the skip; it's a mix of how much waste you have, what it weighs, what it's made of, and even where your site is located.

Think of it like posting a parcel. A small, light package costs peanuts. But a huge, heavy, awkward one? That's going to cost you, especially if it needs special handling. Construction waste works on the exact same principle – every little detail adds up on the final bill. Getting your head around these variables is the first step to setting a realistic budget and avoiding any nasty surprises down the line.

Key Factors That Influence Your Bill

A few key things will dictate how much you end up spending to clear your site waste. Getting these figured out upfront means you can control your costs and make smarter choices right from the start.

- Waste Volume: This is the big one. The more waste you're creating, the bigger the skip or the more collections you'll need. It's simple really – a bathroom rip-out will generate a lot less muck than a full-blown extension.

- Waste Type: Not all rubbish is created equal. A skip full of 'clean' inert waste like soil, bricks, and rubble is usually cheaper to get rid of than a container piled high with mixed general waste, which takes a lot more work to sort back at the recycling facility.

- Hazardous Materials: Anything nasty like asbestos or containers with chemical residue needs specialist handling and disposal, which comes with a much heftier price tag. You absolutely have to budget for these things separately.

- Container Size and Type: A little 4-yard skip for a garden clearance is a world away from the cost of a 40-yard roll-on/roll-off container needed for a commercial demolition. How long you need to keep it on-site will also factor in.

- Location: How close you are to a licensed waste transfer station can nudge transport costs up or down. And don't forget, if you need to put that skip on a public road, you'll need a permit from the council, which is another cost to add to the pot.

Estimating Waste Volume

Trying to guess the volume of waste your project will spit out is where a lot of people go wrong. Underestimate, and you’ll be frantically ordering a second skip at the last minute. Overestimate, and you’re paying for fresh air in a half-empty container. Neither is a good look for your budget.

Using a simple mental picture makes this a whole lot easier.

A standard 8-yard builder's skip – the most common size you'll see on driveways – can hold roughly 60-80 full wheelbarrows of waste. Picturing your pile of rubble in terms of wheelbarrow loads helps you nail the right size from the get-go.

For bigger jobs, you can get a rough idea by calculating the volume of whatever you're knocking down (length x width x height). Just remember to add a buffer of around 10-15%. Materials always 'bulk up' and take up more space once they're broken apart and chucked in a pile.

How Smart Segregation Slashes Costs

Want to know one of the single most effective ways to knock down your waste disposal bill? Sort your materials on-site. When you just chuck everything into one big skip as "mixed waste", the disposal company has to do all the messy, time-consuming work of separating it. That extra labour and processing cost gets passed straight on to you.

By setting up a few separate bins or even just designated piles for different materials, you can turn a cost into a serious saving.

- Clean Wood: Untreated timber is a valuable resource. It can be recycled into things like chipboard or even used as biomass fuel.

- Metals: Scrap metal, like old copper pipes or steel beams, often has a rebate value. You might find a scrap merchant will collect it for free – or even pay you for the privilege.

- Plasterboard: This is a big one. Plasterboard must be kept separate from other waste. Its gypsum content can create harmful gases in landfill conditions, so keeping it isolated prevents you from contaminating an entire skip.

- Inert Waste: Clean soil, bricks, and concrete are relatively simple to recycle into new aggregates for other construction projects, which makes them cheaper to dispose of.

This isn't just about cutting your bill. This proactive approach helps you meet your legal Duty of Care and drastically reduces the amount of waste ending up in landfill. When you stop treating waste management as an afterthought and make it part of the project plan, you protect your budget and your project's green credentials.

Smarter Waste Management On-Site

Truly effective construction waste disposal doesn’t start when the skip arrives; it begins long before the first nail is hammered. The smartest, most cost-effective approach is to be proactive, focusing on preventing waste from ever being created in the first place. This is about shifting your mindset to see every material on your site as a valuable resource, not just future rubbish.

This strategy is often called the 'waste hierarchy', a simple but incredibly powerful principle. The goal is to first Reduce, then Reuse, and only then, Recycle. By weaving these three actions into your daily site operations, you move beyond just getting rid of waste and into intelligent resource management. It's a move that unlocks significant cost savings and seriously boosts your project's environmental credentials.

Reduce Waste From The Outset

The easiest waste to manage is the waste you never create. It’s that simple. This requires a small shift in how you plan, moving from rough guesstimates to precision ordering. Over-ordering materials "just in case" is one of the biggest, and most common, sources of unnecessary site waste.

Instead, get meticulous with your planning. Use your project plans and take accurate measurements to calculate exactly how much timber, plasterboard, or concrete you actually need. This simple step prevents the costly problem of surplus materials cluttering up your site, only to end up in a skip later on.

Another key tactic is to choose your suppliers wisely. Try to work with companies that offer minimal packaging or use returnable containers. Just think about it – reducing the amount of cardboard and plastic wrap arriving on-site is a straightforward but highly effective way to cut down your overall waste volume before the work even begins.

Reuse Materials Creatively On-Site

Before you toss any offcut or leftover into the disposal pile, stop and ask a simple question: "Can this be used somewhere else?" You'd be surprised how often the answer is a resounding yes. This is the 'reuse' part of the hierarchy in action, and it can save you a small fortune.

Consider these practical, everyday examples:

- Timber Offcuts: Those short lengths of wood that might seem useless are often perfect for creating noggins, supports, or packers elsewhere in the build.

- Broken Bricks and Concrete: These can be broken down further and used as hardcore for sub-bases in new paths, patios, or driveways.

- Excavated Soil: As long as it’s clean and uncontaminated, soil can be repurposed for landscaping, filling raised beds, or levelling other areas of the site, avoiding disposal fees entirely.

By setting up a designated 'reuse pile' on-site, you create a go-to resource for your team. This simple habit encourages everyone to check for a suitable offcut before cutting into a brand-new sheet or length of material, directly reducing both waste and your material costs.

Segregate For Efficient Recycling

Once you've squeezed every last drop of value out of reducing and reusing, the final step is efficient recycling. The absolute key to maximising your recycling rates—and minimising your disposal costs—is on-site segregation. Let's be clear: throwing everything into one mixed waste skip is always the most expensive and least environmentally friendly option.

Setting up clearly labelled, separate bins or designated areas for different materials is crucial. Your team should be trained to separate waste as it's generated. This is a fundamental part of any solid construction waste management plan and it helps keep your site organised and compliant.

The UK construction industry produces around 120 million tonnes of waste every year, but modern recycling processes are incredibly effective. For instance, crushed concrete can be recycled with recovery efficiencies of up to 100%, while old asphalt can be reclaimed at rates as high as 95%. It just goes to show the immense potential for turning your site's "waste" back into valuable resources, as long as you segregate it properly.

How to Select a Compliant Waste Carrier

Choosing who takes your construction waste away is one of the biggest decisions you’ll make on any project, and it has a direct impact on your legal standing.

It might be tempting to go with a cheap "man with a van" service, but handing your waste to an unlicensed operator is a massive gamble. If they end up fly-tipping your materials, you are the one who could face unlimited fines for not meeting your Duty of Care. It’s your responsibility, and it’s not one you can pass on.

Think of it like hiring a Gas Safe engineer. You wouldn't let just anyone tinker with your boiler; you’d check their credentials to make sure they're certified and competent. Your waste carrier needs exactly the same level of scrutiny. The legal duty to check they’re the real deal rests squarely on your shoulders.

The Golden Rule: Verify Their Licence

First things first, and this is completely non-negotiable: check their Waste Carrier Licence.

Every single legitimate waste carrier in the UK must be registered with the Environment Agency. This isn't just a bit of admin; it's your only proof that they are legally authorised to transport and dispose of waste.

Always ask for their registration number and then check it yourself on the Environment Agency's public register online. A genuine, professional company will give you this information without a second thought. If they're hesitant or can't provide it, that's a huge red flag. Just walk away.

Key Questions to Ask a Potential Provider

Once you've confirmed their licence is valid and active, it’s time to dig a little deeper. A professional waste management partner will be completely open about how they work.

Here are the essential questions you need to ask:

- What’s your process for Waste Transfer Notes? They must provide a fully completed WTN for every single load they collect. This document is your legal receipt and proof of proper transfer.

- What are your recycling rates? A good provider will be proud of their commitment to keeping waste out of landfill and should be able to give you specific figures.

- How do you handle different types of waste? Ask them how they manage materials like wood, metal, plasterboard, and inert waste. This will show you whether they practice proper segregation for recycling.

Choosing a compliant partner isn't just about ticking boxes; it's about safeguarding your project, your finances, and your reputation. A provider like The Waste Group not only guarantees full compliance with licencing and WTNs but actively helps you maximise recycling, keeping you aligned with industry best practices.

This focus on responsible management is part of a wider positive trend. While construction waste volumes have been fairly stable, the amount of waste generated relative to economic output has actually gone down, thanks to better on-site practices. You can explore the data behind these improvements in the official UK waste statistics. By picking a carrier who champions these principles, you’re making sure you’re part of the solution, not the problem.

Common Questions About Construction Waste Disposal

Let's face it, the world of construction waste can feel like a minefield of rules and regulations. Whether you're a homeowner knee-deep in a renovation or a site manager juggling a dozen trades, you just want clear, straight answers.

Here are some of the most common questions we get asked, with no-nonsense replies to keep you compliant and your project moving.

Can I Put Plasterboard in a General Skip?

In a word: no. This is probably the single most important rule to get right, and one that catches a lot of people out.

Plasterboard contains gypsum. When it gets buried in a landfill and mixes with other damp, organic rubbish, it starts to break down and can release hydrogen sulphide – a toxic and pretty unpleasant gas.

Because of this environmental risk, the law is crystal clear: plasterboard must be kept separate from all other waste. You'll need a dedicated plasterboard skip or bag, or arrange for a specific collection. If you mix it in with your general waste, the entire skip load will be rejected at the tip. That means it gets sent back to you, and you'll be facing extra costs and headaches to get it sorted.

What Is the Difference Between Inert and Mixed Waste?

Getting your head around this is the key to keeping your disposal costs down. It’s simpler than it sounds.

-

Inert Waste: Think of this as the "earthy" stuff that doesn't rot or react. We're talking about soil, clay, rubble, bricks, and concrete. Because it's clean and easy to process – often getting recycled into new aggregates – it's generally much cheaper to get rid of.

-

Mixed General Waste: This is the catch-all skip for everything else. It’s a jumble of materials from your site – things like wood, metal, plastics, and packaging all mixed together. This stuff is more expensive to dispose of simply because it has to be taken to a recycling facility and painstakingly sorted, both by machine and by hand, before it can be processed.

The big takeaway here is that sorting your waste on-site saves you money. A skip filled purely with clean inert waste will almost always be cheaper than a mixed-waste skip of the exact same size.

Do I Need a Waste Carrier Licence for My Own Waste?

This depends entirely on who you are and where the waste came from.

If you're a homeowner clearing out waste from your own house (the one you live in) and you're using your own private car or van to take it to the tip, you do not need a Waste Carrier Licence.

But the moment money changes hands for a job, the rules change. If you're a builder, plumber, landscaper, or any other tradesperson, you must have a Waste Carrier Licence to transport any waste you create as part of your work. It doesn’t matter if it’s just a couple of bin bags in the back of your van – it's a legal requirement. Trading without one can land you with some hefty fines, so it’s always best to check the official government guidelines and make sure you’re covered.

For any project in Dorset, from a small DIY job to a major commercial build, The Waste Group offers fully compliant and straightforward solutions. We handle everything from skip hire to grab lorry services and asbestos disposal, ensuring your construction waste disposal is managed correctly and responsibly. Get a quote and book online today.