A Homeowner’s Guide to Encapsulation of Asbestos in the UK

A Homeowner’s Guide to Encapsulation of Asbestos in the UK

When you hear the term asbestos encapsulation, think of it as a way to safely manage asbestos without the upheaval of a full removal. Instead of taking the asbestos-containing material out, a specialist protective coating is applied over the top. This effectively seals the hazardous material, locking the dangerous fibres in place so they can't become airborne and pose a health risk. It’s a smart and highly effective strategy, but only when the original material is in good shape and just needs protecting from future knocks and scrapes.

What Asbestos Encapsulation Actually Means

Here’s a simple analogy. Imagine you have an old wall painted with lead-based paint. Instead of stripping it all back—a messy and potentially dangerous job—you paint over it with a special, durable sealant. That new layer doesn't get rid of the lead, but it creates a solid barrier, stopping toxic dust from getting into the air. Asbestos encapsulation works on a very similar principle.

It’s a controlled and precise technique for dealing with asbestos-containing materials (ACMs) that are still intact and structurally sound. The real danger with asbestos kicks in when its microscopic fibres get disturbed and released into the air, where they can be breathed in. Encapsulation is designed to stop that exact scenario from ever happening.

A Protective Shield Against Asbestos Fibres

At its core, the method involves applying a specialist sealant directly onto the ACM. This sealant is designed to either soak into the material or form a tough, seamless skin over its surface. Either way, it effectively glues the hazardous fibres together, locking them down permanently. This makes the surface much more resistant to accidental bumps, scrapes, and general wear and tear over time.

This approach is often the preferred choice for a few key reasons:

- Minimal Disturbance: It cleverly avoids the high-risk process of breaking up and removing asbestos, which can release a huge amount of fibres if not handled perfectly.

- Safety First: It contains the hazard right where it is, making an area safe without the major disruption that comes with a full removal job.

- Cost-Effective: As a general rule, encapsulation is cheaper and quicker to carry out than removal, which cuts down on both labour and specialist disposal costs.

The primary goal of encapsulation is simple: safely contain asbestos fibres. A specialised sealant penetrates the material, binding the fibres together and creating a protective barrier that stops them from becoming airborne.

When Is Encapsulation the Right Choice?

So, when should you encapsulate rather than remove? Encapsulation is the go-to strategy when ACMs, like asbestos insulation board or cement sheets, are in good condition but are in a spot where they could get damaged. Think of an asbestos ceiling in a storeroom – if it's in perfect shape, you might encapsulate it to protect it from being accidentally knocked by ladders or equipment. To get a better handle on why managing this material is so critical, you can learn more about what asbestos is in our detailed guide.

However, it’s crucial to understand that encapsulation isn't a silver bullet for every situation. If the asbestos is already badly damaged, crumbling, or is going to be disturbed by major renovation work, then removal is almost always the necessary course of action. The final decision always comes down to a professional risk assessment. This will evaluate the material's condition, its location, and the likelihood of future disturbance, all in line with the UK’s strict Health and Safety Executive (HSE) regulations.

Deciding if Encapsulation Is the Right Call

Choosing between asbestos encapsulation and a full removal isn't a decision to be taken lightly. It's a critical judgement call that balances safety, cost, and UK law. The right path forward depends entirely on the specific situation on the ground – sealing the asbestos might be a perfect solution in one scenario, but dangerously wrong in another. Making this call comes down to a professional evaluation of a few core factors.

The first, and most important, is the condition of the asbestos-containing material (ACM) itself. Is it solid, stable, and in good nick? Or is it friable—a term we use for materials that are soft, crumbly, and easily damaged? An intact asbestos cement sheet on a garage roof, for example, is a classic candidate for encapsulation. Its fibres are locked tightly within the cement, and if the sheet is undamaged, it poses a very low risk.

On the flip side, if you're looking at an asbestos insulation board that's deteriorating, with flaky edges or visible damage, its fibres are far more likely to become airborne. In cases like this, where the material is already degrading, encapsulation is rarely a safe bet. Trying to seal a crumbling material is like trying to paint over rust; you're not fixing the root problem, and the protective layer you apply will probably fail.

Evaluating Location and Potential Disturbance

Next, you have to think about where the asbestos is and how likely it is to be disturbed in the future. Asbestos that's well out of the way, like ceiling tiles in a loft you never use, is much less of a concern than asbestos panels lining a busy school corridor or a boiler cupboard that a plumber needs to access every year.

The key question to ask is: what are the chances of this material being knocked, drilled into, scraped, or otherwise damaged during normal day-to-day life?

- Low-Risk Areas: Materials in places with little human traffic and a low chance of being bumped or bashed can often be safely managed with encapsulation.

- High-Risk Areas: ACMs in spots prone to vibrations, impacts, or regular maintenance work are almost always better off being removed completely to get rid of the hazard for good.

Under the Control of Asbestos Regulations 2012, there's a legal 'duty to manage' asbestos in all non-domestic properties. This means property owners must identify and manage any asbestos present, making the choice between encapsulation and removal a crucial part of staying on the right side of the law.

This is exactly why a professional asbestos survey is non-negotiable. A qualified surveyor won't just tell you if you have asbestos; they'll assess its condition and location to provide a material assessment score, which helps quantify the risk. This expert evaluation is the foundation of any safe and legally compliant asbestos management plan. To understand all the options, you can explore our guide on how to remove asbestos safely.

The Sheer Scale of Asbestos in UK Buildings

The need for such careful decision-making is driven home by the shocking amount of asbestos still lurking in UK properties. A 2022 report highlighted just how big the problem is. Surveyors inspecting over 128,000 UK buildings found that a staggering 78% contained asbestos. The figures for homes were even more alarming, with 86% of domestic properties found to contain asbestos—with an average of nearly five separate instances in each property. You can read more about these startling UK asbestos statistics on Oracle Asbestos.

This widespread presence means countless property owners are facing this exact dilemma. At the end of the day, encapsulation is a management strategy, not a permanent fix. It leaves the asbestos in place, meaning it must be clearly labelled, recorded in an asbestos register, and regularly reinspected to make sure the encapsulant hasn't been damaged. If you've got future renovation or demolition plans for that area, a full removal will be unavoidable anyway.

Asbestos Management Options Compared

To make sense of it all, it helps to see the main options side-by-side. Each has its place, and understanding the pros and cons is key to making a safe and practical decision for your property.

| Method | Best For | Key Benefit | Consideration |

|---|---|---|---|

| Encapsulation | Undamaged, stable ACMs in low-traffic areas. | Less disruptive and more cost-effective than removal. | Leaves asbestos in place; requires ongoing management and monitoring. |

| Enclosure | ACMs that can't be easily removed but are in areas needing protection from damage. | Creates a solid physical barrier around the asbestos. | Can be complex to build and may restrict access for maintenance. |

| Removal | Damaged, friable, or high-risk ACMs, or when planning major refurbishment/demolition. | Permanently eliminates the hazard from the property. | The most expensive and disruptive option, requiring licensed contractors. |

Choosing to encapsulate is a decision that must be made with a clear view of both the immediate benefits and the long-term responsibilities it brings.

The Tools and Materials of Encapsulation

Choosing the right way to encapsulate asbestos is a bit like a surgeon selecting the right instrument for an operation; precision and suitability are everything. You can't just slap on any old paint or sealant. Instead, professionals rely on highly specialised materials, specifically engineered to contain those hazardous asbestos fibres safely for the long haul.

The choice of material really comes down to the type of asbestos-containing material (ACM) you're dealing with, and what sort of condition it's in. This isn't a random decision; there's a clear logic to it, all designed to create the most durable and protective seal possible. The materials fall into two main camps, and each one has a very different job to do.

Penetrating vs Bridging Encapsulants

First up, you have penetrating encapsulants. Think of this stuff as a super-strong glue that soaks deep into the fabric of the asbestos material. It's the perfect choice for porous or more crumbly (friable) materials, like asbestos insulation board or old sprayed coatings. As it gets absorbed, it binds all those microscopic asbestos fibres together from the inside, essentially solidifying the material and making it far less likely to break apart and release dust.

The other option is a bridging encapsulant. This works in a completely different way. Instead of soaking in, it creates a thick, tough, and often flexible skin over the surface of the ACM. Imagine painting a thick layer of liquid rubber over something – it forms a seamless, heavy-duty membrane that completely seals whatever is underneath. This approach is ideal for less porous surfaces like asbestos cement sheets or textured coatings like Artex, giving them a robust shield against knocks and scrapes.

The core idea is simple: match the tool to the job. Penetrating encapsulants lock fibres together from within, while bridging encapsulants create a tough outer shield. Both stop fibres from being released, but they get there in different ways.

Getting this distinction right is crucial for making sure the encapsulation lasts. If you used a bridging encapsulant on a very soft, friable material, it might just peel away over time because the surface underneath isn't stable. On the other hand, a penetrating encapsulant wouldn't give a hard cement sheet enough protection from physical damage.

The final call between these methods always comes down to a professional assessment of the ACM's condition, where it's located, and how likely it is to be disturbed in the future.

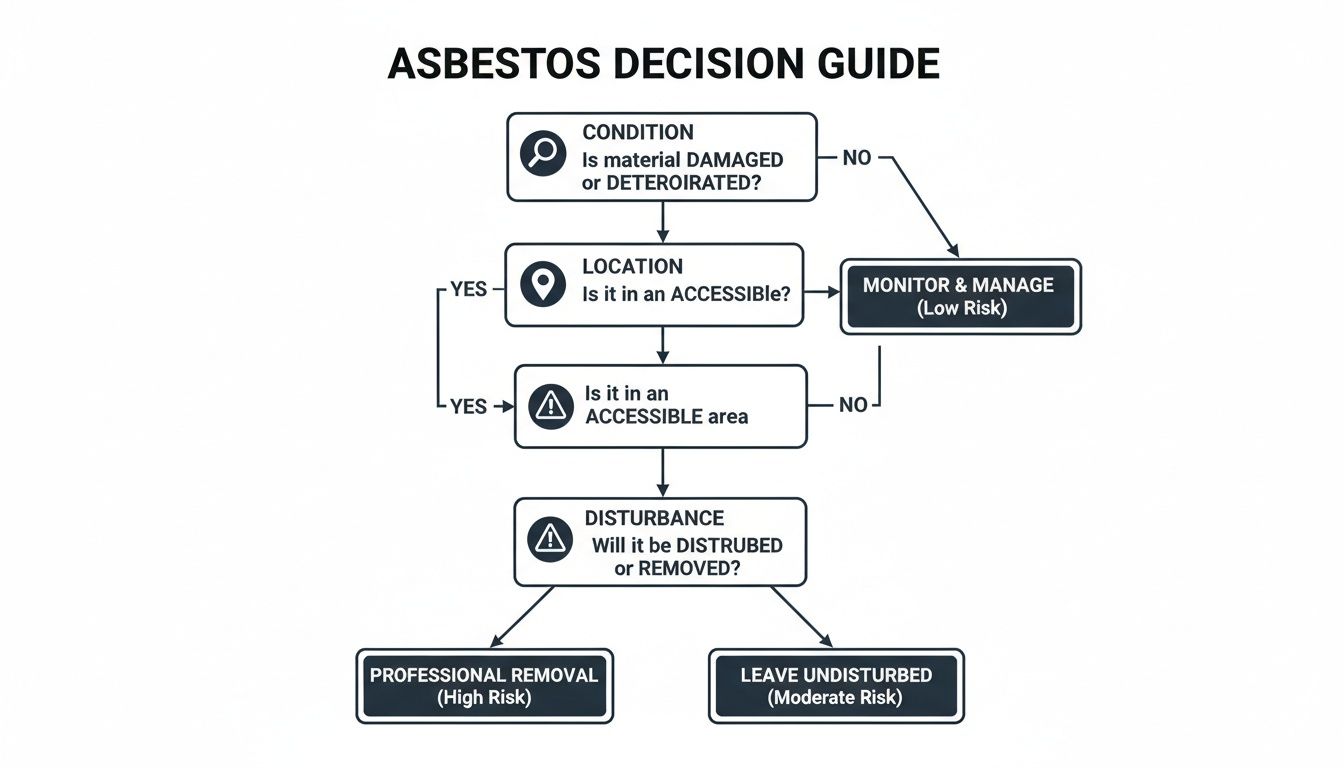

This flowchart helps to visualise the key decision points a professional works through when putting together an asbestos management plan.

As the guide makes clear, things like the condition of the material and the risk of disturbance are critical in deciding whether encapsulation is a safe and sensible route to take.

Beyond Basic Sealants

Modern encapsulants are seriously advanced formulas with properties that go way beyond simple sealing. Many are designed with specific jobs in mind:

- Durability and Impact Resistance: They are built to withstand knocks and scrapes far better than standard paints, which is vital in busy areas.

- Fire Retardancy: Some encapsulants add an extra layer of fire protection, boosting the overall safety of the building.

- Flexibility: Many coatings are elastomeric, which means they can stretch and move as a building naturally expands and contracts, all without cracking.

- Chemical Resistance: In industrial environments, specialist coatings can shield ACMs from harsh chemicals.

You really can't overstate how important it is to use these professional-grade materials, especially when you think about the public health crisis asbestos still represents in the UK. With asbestos-related deaths in Great Britain topping 5,000 each year, encapsulation is a frontline defence. In fact, studies show that properly applied encapsulants can cut the risk of fibre release by up to 90%, making them an essential tool for managing the asbestos still present in an estimated 1.5 million UK buildings. You can read more about this ongoing public health issue on Prospect Magazine.

This is why getting a professional to apply the correct materials isn't just a good idea—it's a critical safety requirement.

Weighing Up the Pros and Cons of Encapsulation

Deciding how to manage asbestos in your property isn't a small decision. Like any important choice, encapsulation of asbestos has its own clear benefits and some serious drawbacks. Getting your head around these is the only way to make a responsible choice that keeps your building, and the people inside it, safe.

There’s no magic bullet here. The right path forward really depends on your specific situation, your budget, and what you plan to do with the building in the long run. By carefully considering these points, you'll know exactly what you’re signing up for – not just the immediate upsides, but the future responsibilities that come with sealing asbestos in place.

The Clear Advantages of Encapsulation

Let’s be honest, the biggest reason people choose encapsulation is that it’s cost-effective. A full-blown asbestos removal is a massive undertaking. It’s complex, labour-intensive, and involves specialist hazardous waste disposal, all of which sends the costs soaring. Encapsulation is a different beast entirely – it’s typically much quicker and uses fewer resources, making it a far more wallet-friendly option.

Another huge plus is the minimal disruption. Tearing out asbestos can mean shutting down part of your property for a good while, with everything done under tightly controlled conditions. Encapsulation is way less intrusive. The work gets done quickly, with much less impact on your daily life or business operations.

And finally, it’s just an inherently safer process. Why? Because you’re not disturbing the asbestos-containing material (ACM). The moment you start breaking up asbestos, you risk releasing those dangerous fibres into the air. By sealing it in, you neatly sidestep that primary hazard.

The Important Considerations and Drawbacks

The biggest drawback is a simple, unavoidable fact: the asbestos is still there. Encapsulation isn't about getting rid of the problem; it's about managing it safely. This creates a long-term responsibility that you can't ignore.

An encapsulated surface is not a "fit-and-forget" solution. It must be officially recorded in your property's asbestos register and is subject to a long-term management plan, which includes regular inspections to check the integrity of the seal.

That protective coating isn’t indestructible. A deep gouge from moving furniture, an accidental knock, or even just building vibrations over many years could break the seal. If that encapsulant gets breached, the risk of fibre release is right back on the table, and you might be looking at an urgent repair or even a full removal after all. This need for constant vigilance is a massive factor to weigh up.

The presence of encapsulated asbestos can also throw a spanner in the works for future renovation or demolition plans. If you ever decide to do major structural work in that area, the asbestos will almost certainly have to be professionally removed first, adding a whole extra step and cost to your project down the line.

This tight regulation comes from the UK's long and troubled history with the material. To give you some context, raw asbestos imports shot up from 24,000 tonnes in 1930 to a staggering peak of 187,000 tonnes in 1964, leaving a huge and dangerous legacy in our buildings. You can read more about the UK's past relationship with asbestos on Britsafe.org. It's this legacy that explains why the ongoing management of encapsulated asbestos is taken so seriously.

Encapsulation vs Removal: A Cost and Impact Overview

To help you visualise the trade-offs, it’s useful to see the two main options side-by-side. This table breaks down the key differences in cost, disruption, and what they mean for your property long-term.

| Factor | Asbestos Encapsulation | Asbestos Removal |

|---|---|---|

| Initial Cost | Significantly lower. Less labour, fewer materials, and no specialist disposal fees. | Much higher. Involves extensive labour, containment, and licensed hazardous waste disposal. |

| Disruption | Minimal. The process is quicker and less intrusive, often allowing normal operations to continue. | High. Requires vacating the area, extensive setup, and can take a considerable amount of time. |

| Long-Term Responsibility | Ongoing. Requires a management plan, regular inspections, and careful maintenance. | None. Once removed and verified, the asbestos liability for that area is permanently gone. |

| Future Works | Complicates things. Future renovation or demolition will likely require removal first. | Simplifies future works. No asbestos-related hurdles for future renovations or demolition. |

| Property Value | Can be a perceived negative for some buyers due to the ongoing management requirement. | Can increase property value as the asbestos risk has been completely eliminated. |

Ultimately, choosing encapsulation means accepting a lower upfront cost in exchange for a permanent management responsibility. Removal costs more now but provides a final, walk-away solution.

Finding a Qualified Asbestos Contractor

Let’s be crystal clear: managing asbestos is not a DIY job. The risks are simply too high, and the regulations are watertight for a very good reason. When you're dealing with asbestos encapsulation, picking the right professional isn’t just a good idea—it's a legal and safety must-have.

The very first check is to make sure any contractor you're considering holds a valid licence from the Health and Safety Executive (HSE) for asbestos work. This is non-negotiable. It’s the official stamp that proves they have the right training, gear, and safe procedures to handle this dangerous material. They must also have comprehensive insurance that specifically covers asbestos-related jobs.

Vetting Your Potential Contractor

Once you've got a shortlist of licensed pros, it’s time to do your homework. Asking the right questions is the only way to properly vet their skills and make sure they’re a good fit for your project. Don't feel awkward about being thorough; any reputable company will welcome your diligence.

Here are a few essential questions to get you started:

- Experience with Encapsulation: "Can you show me some examples of similar asbestos encapsulation projects you’ve handled before?"

- Materials and Methods: "What specific encapsulant products do you use, and why are they the best choice for my situation?"

- Safety Protocols: "What safety measures will you be putting in place to protect my family and property while you're working?"

- Waste Management: "How do you handle the contaminated waste, like used overalls and cleaning materials, that the job will create?"

If you're new to this, looking into the process of hiring a building consultant can give you a good general idea of how to check professional credentials and ask the right questions.

Understanding the Waste Disposal Chain

One of the most critical parts of any asbestos job—and one that often gets overlooked—is waste management. Even a straightforward encapsulation project creates contaminated materials. We’re talking about used personal protective equipment (PPE), cleaning rags, masking tape, and anything else that has touched the asbestos.

Under UK law, all of this is classed as hazardous waste and needs to be handled with military precision.

A professional asbestos contractor must have a fully compliant, legally sound process for waste disposal. This involves working with a licensed hazardous waste carrier to ensure every single contaminated item is properly bagged, labelled, and taken to a designated hazardous waste facility.

This is a vital link in the safety chain. Don’t be shy about asking a potential contractor to walk you through their waste disposal plan. They should be able to tell you exactly who their licensed waste partner is and what their procedures are. This gives you peace of mind that the asbestos risk isn't just being shifted from your property to somewhere else, but is being managed correctly from start to finish.

For more tips on choosing a specialist, have a read of our guide on how to choose the right asbestos removal company. The advice there is just as relevant for finding a top-notch encapsulation expert. By following these steps, you’ll be ready to take the next safe, legal, and practical step towards protecting your property.

Common Questions About Asbestos Encapsulation

Even when you've got your head around the basics, it's completely normal to have a few lingering questions about the practical side of asbestos encapsulation. It's a safe and effective way to manage asbestos, but it’s not a one-and-done job; it comes with long-term duties that are crucial to get right.

Let's run through some straightforward answers to the most common queries we hear. These should help clear up any final uncertainties and give you the confidence to make the right call for your property.

Is Encapsulation a Permanent Fix?

This is probably one of the most important questions people ask, and the simple answer is no. Asbestos encapsulation isn't a permanent removal – think of it more like a long-term management plan. The specialist sealants used are incredibly durable and designed to last for many years, often 10-20 years if left undisturbed.

However, the asbestos itself is still there underneath. This means the area must be clearly noted in your asbestos register and inspected regularly by a professional. These checks are vital to make sure the protective layer hasn't been damaged, keeping everyone safe.

Can I Just Paint Over Asbestos Myself?

Absolutely not. This is a very dangerous idea that could have serious health consequences. Your standard tin of emulsion or gloss paint from the local DIY shop is not an asbestos encapsulant. It just doesn't have the right chemical makeup to soak into the material and bind those lethal fibres together.

Worse still, the preparation work for painting – like sanding or scraping – is one of the most high-risk activities you could possibly do. It will almost certainly disturb the asbestos, releasing a cloud of invisible fibres straight into the air. Only trained professionals using HSE-approved products should ever tackle this job.

Trying to do a DIY job with regular paint doesn't just fail to seal the asbestos; it makes a dangerous situation even worse. The process requires specialist materials and strict safety measures to be both effective and legal.

How Do I Know if the Seal Is Damaged?

After the professionals have finished the job, it’s good practice to know what to look for. Keeping an eye on the encapsulated surface is key, and any signs of damage need to be flagged up with a licensed contractor immediately.

Be on the lookout for tell-tale signs that the seal has been broken:

- Cracking or Flaking: Any visible splits or breaks appearing in the coating.

- Peeling or Blistering: The sealant looks like it’s lifting away from the surface.

- Gouges or Deep Scratches: Obvious physical damage that has cut through the protective layer.

- Water Damage: Any damp patches or stains that could be weakening the sealant.

If you spot any of these problems, treat it as a potential hazard. Keep people away from the area and get a professional asbestos specialist on the phone to come and assess it properly.

What Happens to Waste from the Job?

Good question. Even though encapsulation leaves the asbestos material in place, the work itself still creates some hazardous waste. This includes things like the disposable coveralls (PPE), rollers, brushes, masking tape, and any cleaning cloths.

Under the Control of Asbestos Regulations 2012, all this waste is officially classed as hazardous. It must be double-bagged in specific red and clear asbestos waste sacks, clearly labelled. A licensed contractor will then ensure a registered hazardous waste carrier collects it for transport to a special landfill equipped to handle it. This strict process ensures every last trace of asbestos is managed safely and legally.

Managing any asbestos project, especially the final, critical step of waste disposal, demands professional handling. For fully compliant and reliable asbestos disposal services, you need to trust the specialists. Contact The Waste Group today to make sure your project is handled safely from beginning to end. https://www.thewastegroup.co.uk