Is Wood Recyclable? A Guide to Proper Wood Disposal

Is Wood Recyclable? A Guide to Proper Wood Disposal

Yes, most wood can be recycled, but there’s a big catch—it all comes down to the type of wood you’re dealing with. Clean, untreated timber is a recycler’s dream. Wood that’s been painted, glued, or pumped full of chemicals? Not so much.

What It Really Means When We Ask If Wood Is Recyclable

Think about sorting your weekly rubbish. You wouldn't toss a glass bottle into the paper bin, and the same logic applies to wood. The journey a piece of waste wood takes from your project to its next life is completely defined by its past. A clean offcut from a new fence post is worlds away from an old, painted garden gate.

So, the real question isn't just "can you recycle wood?" It's "has this specific piece of wood been contaminated?" Things like paint, varnish, glues, and chemical treatments are the enemy of recycling. These additives can leach harmful substances or just ruin the quality of the final recycled product.

The Sorting Process: A Simple Analogy

Imagine a fast-moving conveyor belt at a recycling plant. Clean, natural bits of wood are easy to spot. They get pulled off and sent on their way to become useful things like animal bedding or garden mulch.

But then, along comes a piece of decking that's been pressure-treated. It gets flagged immediately and pulled from the line. That piece needs a totally different, more specialised disposal route to stop its chemicals from contaminating the entire clean batch. This sorting stage is the most crucial step in the whole process.

The UK's waste wood industry has become incredibly efficient at this. In fact, it now handles over 96% of the 4.5 million tonnes of waste wood we generate each year. That’s a massive 4.33 million tonnes saved from landfill and put back to use through reuse, recycling, or energy recovery. For a deeper dive into these numbers, you can read the full report from the Wood Recyclers' Association.

What Makes Wood Recyclable (Or Not)?

So, what are the main things that decide if your wood waste makes the cut? It really just boils down to a few key factors:

- Treatments: Has it been pressure-treated, soaked in creosote, or coated with other chemical preservatives? If the answer is yes, it generally can't go into the standard recycling stream.

- Coatings: A lick of paint, a coat of varnish, or a laminate finish are all contaminants. They can easily spoil a whole batch of recycled wood pulp or chips.

- Glues & Resins: Engineered woods like MDF (Medium-Density Fibreboard) and chipboard are stuck together with powerful adhesives. This makes them tricky to recycle alongside natural timber.

- Contaminants: It’s not just about the wood itself. Any extras—nails, screws, hinges, or plastic fittings—have to be removed before the wood can be processed.

Getting your head around these differences is the first step to getting rid of your wood waste the right way. It’s what ensures your old timber becomes part of a sustainable cycle, instead of just another item piled up in a landfill.

Understanding the Official Grades of Waste Wood

Not all wood is created equal, especially when it comes to recycling. To really get a grip on whether a piece of wood can be recycled, you need to understand the official grading system the waste industry uses. Think of it like sorting apples at a farm shop—some are perfect for eating fresh, while others are destined for cider. In the same way, waste wood is sorted into grades to figure out its best possible next life.

This system, which runs from Grade A to Grade D, is the backbone of effective wood recycling. Each grade signals a different level of purity and potential contamination, which in turn decides whether it can become a high-quality new product or needs more specialised (and costly) handling. Getting this right is absolutely crucial; mixing just one piece of lower-grade wood with a high-grade batch can contaminate the whole lot.

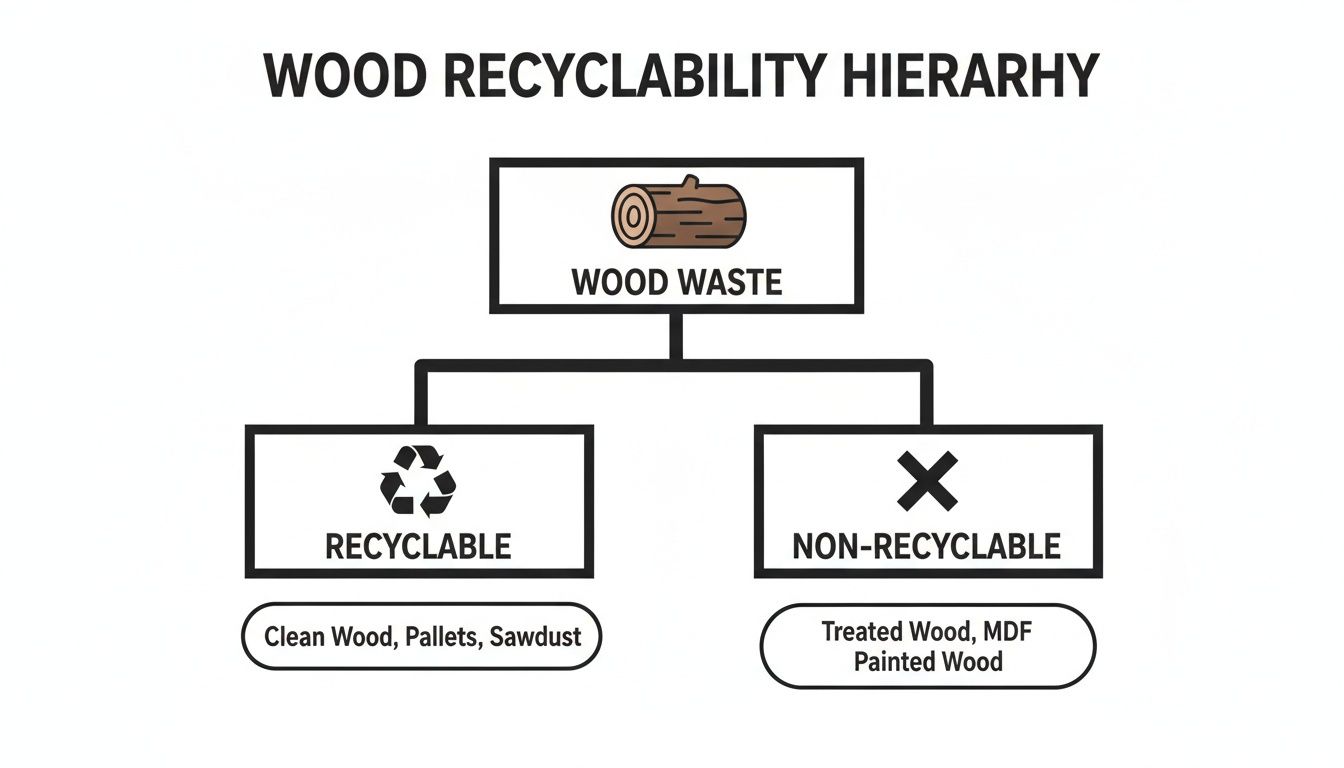

This simple diagram shows the basic split between wood that can be recycled and wood that can't.

As you can see, the journey for waste wood starts with a key decision based on what it is and how it’s been treated in the past.

Grade A: The Clean Wood

Grade A is the top tier of waste wood, what we often call ‘clean’ or ‘virgin’ timber. This category is for wood that is completely untreated and unpainted. It’s the purest stuff you can get, making it incredibly valuable for recycling.

You’ll typically find Grade A wood in the form of:

- New timber offcuts from construction or manufacturing jobs.

- Untreated wooden pallets and packing cases.

- Sawdust and shavings from processing clean timber.

Because it's so pure, Grade A wood has the most recycling options. It can easily be turned into premium products like animal bedding, garden mulch, and even safe play surfaces for playgrounds, all without any fear of contamination.

Grade B: The Construction Mix

Grade B is a step down in purity, but it still has plenty of recycling potential. This grade is usually the mixed bag of wood waste that comes from construction and demolition sites. It might have a little bit of paint on it, or other coatings, and will likely have things like nails or screws attached.

This is the kind of timber you get when dismantling old buildings—think roof timbers, floorboards, and solid wood doors. While it’s not as pristine as Grade A, modern processors have advanced machinery that can yank out the metal and clean the wood up, getting it ready for its next life.

Grade B wood is often shredded and pressed into panel boards, like chipboard or oriented strand board (OSB). A huge amount of it is also used as biomass fuel to generate renewable energy.

Grade C: The Engineered Wood

With Grade C wood, recycling gets a bit more complicated. This category is mostly made up of engineered wood products like Medium-Density Fibreboard (MDF), chipboard, and plywood. These materials are manufactured by binding wood fibres, particles, or thin sheets together with resins and glues.

It’s those adhesives that cause the problems. They make Grade C wood unsuitable for high-grade recycling uses like animal bedding, as the resins can release chemicals during processing and spoil the final product. However, it’s a brilliant feedstock for the biomass industry, where it’s burned to produce energy.

Grade D: The Hazardous Wood

Finally, we have Grade D. This is the lowest classification and is treated as hazardous waste. This is wood that has been treated with preservatives like creosote or other dangerous chemicals that can seriously harm the environment and our health if not handled properly.

The main culprits to watch out for are:

- Railway sleepers (often treated with creosote).

- Old telegraph poles.

- Wood treated with specific industrial chemicals for things like fencing or decking.

This type of wood cannot be recycled through normal channels and must never be mixed with other grades. It requires specialist collection and disposal at licensed facilities to make sure it's handled safely, preventing nasty chemicals from leaching into the soil and water. Knowing this is vital for anyone asking, "is wood recyclable?" because getting rid of Grade D wood incorrectly comes with serious legal risks.

The Journey of Wood From Your Skip to Its New Life

When you hire a skip and fill it with old timber, flooring, or garden fencing, you might think its story is over. But it's not. That collection of wood is about to embark on a fascinating journey, turning what was once rubbish into valuable new resources. This is where your choice to dispose of it properly makes a real, positive difference.

That journey begins the second our lorry collects your skip. All the mixed waste is taken straight to a specialised sorting facility, known as a Materials Recovery Facility (MRF). Think of an MRF as a highly organised hub where clever tech and human expertise work together to separate every last bit of material. What happens here determines your old wood’s exciting second life.

The Sorting Stage

Once your skip’s contents arrive at the MRF, they're carefully unloaded. The first step is a mix of machine power and human skill. Large machinery, like powerful grabs, will pick out the bulky pieces of wood, separating them from other waste like metal, plastic, or rubble.

From there, the wood is moved onto conveyor belts where our skilled team gets to work on a more detailed sort. Their job is to identify and segregate the wood based on its grade—a crucial step we talked about earlier. They're on the lookout for contaminants like paint, glue, and chemical treatments, making sure Grade A, B, and C woods are all channelled down the right path.

At The Waste Group, our mission is to divert as much waste from landfill as possible. Our advanced sorting processes ensure that we recover wood for recycling or energy generation, contributing to a more sustainable future.

New Life for Clean Grade A Wood

Clean, untreated Grade A wood has the most exciting and valuable recycling options. Once separated, it’s usually fed into industrial shredders or chippers that break it down into uniform pieces. This processed material is highly sought after for several eco-friendly uses.

One of the most common destinations for Grade A woodchip is agriculture. Its clean, absorbent nature makes it perfect for creating high-quality animal bedding for livestock and poultry. It provides a comfortable, hygienic environment for the animals, and once used, it can be composted along with other farm waste.

Another popular use is in horticulture. Once wood waste is collected, one common and beneficial 'new life' it can find is through professional tree mulching services. The resulting garden mulch is brilliant for helping soil retain moisture, suppressing weed growth, and enriching the soil with nutrients as it slowly breaks down.

Repurposing Grade B and C Wood

Wood from Grades B and C, which includes things like demolition waste and engineered woods like chipboard, follows a different but equally important path. First, any metal bits like nails and screws are yanked out by powerful magnets, then this wood is also chipped.

These woodchips are often destined for the panel board industry. They get mixed with resins, compressed under intense heat and pressure, and transformed into new panel boards like chipboard and Oriented Strand Board (OSB). These boards are then used to manufacture new furniture, flooring, and construction materials—closing the loop perfectly.

A huge chunk of Grade B and C wood also becomes a vital fuel source for the renewable energy sector. It’s used as biomass fuel in specialised power plants, where it's burned to generate electricity and heat. This process provides a greener alternative to fossil fuels, cutting down our carbon emissions and reliance on non-renewable resources. To see how this fits into the broader picture, you can learn more about what happens to everything in your skip in our detailed guide.

This whole journey—from a skip on your drive to a bag of animal bedding or a newly made floorboard—shows why asking "is wood recyclable?" is so important. Your decision to dispose of wood correctly directly fuels these sustainable industries.

Which Types of Wood Can Never Be Recycled?

While a huge amount of wood waste can be recycled or recovered, it’s vital to know that not all timber gets a welcome pass. Some types of wood aren't just tricky to process; they can be downright harmful, loaded with chemicals that can contaminate entire batches of clean wood.

Think of it like this: you wouldn't toss a mouldy piece of fruit into a fresh smoothie because it would ruin the whole thing. The same logic applies here. One wrong piece of treated wood can force a whole lorryload to be diverted straight to landfill, undoing all the good work.

Getting a handle on which types of wood to keep separate is the single most important step for responsible disposal.

Chemically Treated Wood: The Biggest Offender

By far, the most common and hazardous group of non-recyclable wood is anything that’s been chemically treated to fend off rot, insects, or fire. These treatments soak the wood in powerful chemicals that are fantastic for making it last longer in your garden, but a total disaster for recycling.

Pressure-treated wood is the classic example. You’ll recognise it as the greenish-tinted timber often used for garden decking, fence posts, and landscaping sleepers. It's packed with chemical preservatives that can leach out during recycling, contaminating soil and water.

Likewise, creosote-treated wood, like old railway sleepers and telegraph poles, is actually classified as hazardous waste. Creosote is a toxic substance, and this kind of wood needs specialist handling and disposal at a licensed facility to prevent serious environmental damage. It should never be tossed into a general waste skip.

Popping hazardous wood like railway sleepers into a standard skip isn’t just a major environmental no-no; it can land you with some hefty fines. Always let your waste management provider know about any hazardous materials to make sure everything is handled safely and by the book.

Engineered and Composite Woods

Another group of materials that can’t be recycled in the traditional sense are engineered or composite woods. These are products made by squashing and bonding wood fibres, particles, or thin sheets together with heavy-duty adhesives and resins. All that glue makes it impossible to separate the raw wood fibres for reuse.

Keep an eye out for these main culprits:

- Medium-Density Fibreboard (MDF): A staple of flat-pack furniture and kitchen cabinets, MDF is made from fine wood fibres mixed with wax and resin binders.

- Chipboard (Particleboard): You'll find this in everything from kitchen worktops to cheap flooring. It’s essentially compressed wood chips and sawdust held together by synthetic resin.

- Laminated Wood: This covers things like laminate flooring or furniture with a plastic-coated finish. That thin plastic layer just can't be separated from the wood fibre beneath it.

While you can't turn these items back into things like animal bedding, many of them can be recovered and used as biomass fuel to generate energy.

Common Non-Recyclable Wood and Why

To make it even clearer, here’s a quick rundown of common wood items that can't go in the recycling pile, why that is, and what you should do with them instead.

| Non-Recyclable Wood Item | Reason It Cannot Be Recycled | Correct Disposal Method |

|---|---|---|

| Pressure-Treated Wood | Contains chemical preservatives (like arsenic or copper) that are toxic and can contaminate soil and water. | Specialist hazardous waste disposal. Check with your local council or a licensed waste carrier like The Waste Group. |

| Railway Sleepers | Treated with creosote, a hazardous substance that is harmful to the environment and human health. | Must be disposed of as hazardous waste through a licensed facility. Never burn or place in a general skip. |

| MDF & Chipboard | The resins and glues used to bind the wood fibres cannot be separated, making traditional recycling impossible. | Can often be sent for energy recovery (biomass fuel). Check with your waste provider or local recycling centre. |

| Laminated Flooring | The plastic laminate layer is fused to the wood composite base and cannot be separated for recycling. | General waste or check with your local tip for specific disposal advice. Some can be used for energy recovery. |

| Burnt Wood | The chemical structure is altered by fire, and it contains soot and other contaminants that spoil the recycling process. | Small amounts can go in general waste. For larger quantities from a fire, consult a professional waste service. |

| Heavily Painted/Varnished Wood | Old paints (especially pre-1970s) can contain lead. Modern paints and varnishes contain chemicals that contaminate recycled wood products. | Check with your local Household Waste Recycling Centre. Some may accept it, others will direct it to general waste. |

Remember, correctly identifying these materials is half the battle. By keeping them separate, you give the clean wood a fighting chance to be recycled properly.

Other Non-Recyclable Wood Items

Beyond the main categories, a few other common items are also banned from the wood recycling stream due to contamination.

Burnt Wood: Wood that's been in a bonfire or a building fire is a no-go. The charring changes its chemical makeup and it can be riddled with soot and other nasty residues that would ruin a clean batch.

Painted or Varnished Wood: While some facilities can handle lightly painted wood (Grade B), heavily coated items are often turned away. The chemicals in paints and varnishes can release harmful fumes when processed and will spoil the quality of the final recycled product.

Wood with Contaminants: Any timber that’s heavily mixed with other materials is a problem. This includes wood with big chunks of plaster, insulation foam, tar, or large metal and plastic attachments that aren't easy to remove.

Nailing these exclusions is crucial. When you correctly identify and separate these non-recyclable woods, you ensure the rest of your waste timber can be successfully turned into something new, supporting the circular economy and doing your bit for the environment.

How to Prepare Your Wood Waste for Recycling

Knowing what kind of wood can be recycled is one thing, but making sure it actually gets recycled is another. A little bit of prep work goes a seriously long way. Think of it like cooking: if you don't chop the veg or measure the flour, the final dish is never going to be quite right.

Getting your wood waste ready ensures recycling facilities can handle it safely and efficiently. This means more material gets a second life and contamination is kept to a minimum. Whether you’re a homeowner knee-deep in a DIY project or a professional on a busy construction site, these simple steps are your ticket to successful wood recycling.

Step 1: Decontaminate and Strip Your Wood

First things first, you need to strip the wood of anything that isn't wood. The machinery at recycling plants is built to process timber, not a jumble of different materials. Stray bits of metal or plastic can wreck shredders and grinders, causing expensive damage and bringing the whole operation to a halt.

Before you chuck any wood into your skip, give it a once-over and pull off these common culprits:

- Metal Fixings: Screws, nails, bolts, hinges, and brackets all have to go.

- Plastic Components: Get rid of any handles, decorative trims, or plastic wrapping.

- Other Materials: Any attached glass, fabric, or large chunks of plasterboard need to be removed.

Spending just a few minutes prying off a hinge or unscrewing a handle makes a massive difference. This simple action boosts the quality and value of your wood waste, making it a prime candidate for being turned into something new.

Step 2: Keep It Dry and Clean

Moisture is the arch-nemesis of wood recycling. When timber gets soaked and stays wet, it starts to rot. This decomposition breaks down the wood fibres, making them totally useless for creating high-quality recycled products like animal bedding or panel boards.

Crucial Tip: Wet wood isn’t just lower in quality; it's also a lot heavier. This can push up the weight of your skip, which might affect your disposal costs, and makes it tougher for the recycling facility to handle.

To avoid this, do your best to keep your wood waste dry. If you’re storing it outside before it gets collected, just throw a tarpaulin over it. This will shield it from the rain and make sure it arrives at the processing plant in top condition, ready for its next chapter. It's also a good idea to keep it clear of mud, soil, and other general rubbish.

Step 3: Source Segregation Is Key

One of the smartest moves you can make in waste management is source segregation. It sounds a bit technical, but the idea is simple: keep different types of waste separate from the start.

Instead of piling clean timber, treated fence posts, and general rubbish all together, sort them as you generate them. This is especially vital for wood. If you have clean, untreated Grade A wood, keep it separate from any painted, treated, or engineered wood. The moment you mix them, the clean wood is considered contaminated, and the whole load could be downgraded or even rejected for recycling.

Learning how to juggle different materials on-site is a game-changer, and our guide on using green waste skip bins has more useful tips on how to sort effectively.

By sticking to these straightforward steps, you give your wood waste the best possible chance of being recycled properly. Not only does this help the circular economy, but it also keeps you on the right side of waste regulations and contributes to a more sustainable way of building and renovating.

Finding the Right Wood Waste Disposal Solution

Knowing what wood you can recycle is one thing, but making it happen is the real challenge. Choosing the right disposal method is what turns your good intentions into genuine environmental benefits. It all comes down to finding a reliable partner who doesn't just take your waste away but guarantees it’s handled the right way.

For homeowners and businesses with waste from their projects, a common thought is to look into junk removal services for old furniture and renovation debris. However, for most projects, big or small, hiring a skip is often the most straightforward and cost-effective approach. The trick is simply to match the skip size to your needs, so you aren't paying for empty space or having to arrange multiple trips.

Selecting the Right Skip Size

Getting the skip size right is crucial for both your wallet and your convenience. A small garden clear-out with a few old fence panels has completely different needs than a major construction site churning out tonnes of timber.

Here’s a quick guide to help you match the skip to the job:

- Small DIY or Garden Projects: A 4-yard skip is usually perfect for minor renovations or clearing out the shed. It’s big enough to hold about 40 bin bags worth of waste.

- Larger Home Renovations: If you're tackling a kitchen refit or a big garden landscaping job, a 6 or 8-yard skip gives you plenty of room for old floorboards, kitchen units, and bigger offcuts.

- Commercial and Construction Sites: For really substantial volumes of wood, roll-on/roll-off (RoRo) bins are the industry standard. These containers, which go up to a massive 40 yards, are built for heavy, bulky materials and are essential for keeping large sites clear and safe.

What to Look for in a Waste Partner

When it’s time to get rid of your wood, the waste management company you choose makes all the difference. Not every provider is focused on sustainability. A great partner offers more than just a big metal box; they give you the peace of mind that your waste is being fed back into the circular economy.

A reputable waste management company will be transparent about its processes. At The Waste Group, we are proud of our commitment to diverting over 95% of the waste we collect from landfill, ensuring your wood is recycled or recovered for energy whenever possible.

Look for a company with a clear, proven commitment to high recycling rates. They should operate their own licensed sorting facilities and be able to tell you exactly what happens to your wood after it leaves your site. For more clarity on what is and isn't allowed, check out our helpful guide detailing what can go in a skip. This kind of transparency is the hallmark of a partner you can trust.

Got Questions About Wood Recycling? We’ve Got Answers.

Even when you’ve got the basics down, a few specific questions always seem to pop up when you're faced with a pile of wood waste. We hear them all the time from our customers. Here are some quick, straightforward answers to help you make the right call.

Can You Recycle Wood With Nails In It?

Yes, in most cases, you absolutely can. Modern recycling facilities are pretty clever bits of kit, equipped with powerful magnets and advanced machinery designed to whip out metal bits like nails, screws, and staples as the wood gets processed. This kind of wood usually falls into the Grade B category.

That said, it’s always a good idea to pull out any big nails or screws if you can. It just helps the whole process run a bit smoother and is kinder to the machinery on the other end.

Can I Put Old Furniture in a Skip for Recycling?

This one really depends on what the furniture is made from. That solid pine table that’s seen better days? It can often be recycled. It’ll likely be classed as Grade B waste, especially if it’s got a lick of paint or varnish on it.

But what about that flat-pack bookshelf? Furniture made from MDF or chipboard is a different story. It’s considered Grade C, and while it can’t be turned back into new wood products, it can be recovered and used for biomass fuel. If in doubt, just ask your waste provider.

The golden rule here is separation. If you can keep your solid wood items separate from the MDF and chipboard stuff, you give it the best possible chance of being properly recycled. Contamination is the number one enemy of effective wood recycling.

Is All Pallet Wood Safe to Reuse or Recycle?

Not always, so it pays to be careful. The majority of pallets you’ll find in the UK and Europe are perfectly safe – look for an ‘EPAL’ or ‘EUR’ stamp. They’re heat-treated (marked with ‘HT’).

However, some older pallets, or those from outside the EU, could have been treated with nasty chemicals like methyl bromide, a toxic fumigant. These are usually marked with ‘MB’.

If you find a pallet with no markings or you’re just not sure where it came from, it’s best to play it safe. Don’t use it for a DIY project or as firewood. The good news is, you can still pop it in a mixed wood skip, and the professionals at the recycling facility will grade it correctly for you.

At The Waste Group, we take the hassle out of wood waste. Whether you're clearing out the garden or running a major construction site, our skips and dedication to recycling mean your waste is handled the right way. Book your skip online today and let us handle the heavy lifting.