A Complete Guide to the Recycling of Aggregate in the UK

A Complete Guide to the Recycling of Aggregate in the UK

When you hear the term aggregate recycling, what comes to mind? Essentially, it’s the process of taking waste from construction and demolition sites—think old concrete, bricks, and rubble—and crushing it down to create brand-new building materials.

This isn't just a clever trick; it's a vital part of making the construction industry more sustainable. By reusing these materials, we slash the amount of waste heading to landfill, conserve our precious natural resources, and seriously cut down the industry's carbon footprint.

The Growing Importance of Aggregate Recycling

Imagine our planet’s resources as a massive library, but one with a limited number of books. For decades, the construction world has been pulling these "books"—raw aggregates like sand, gravel, and stone—off the shelves without ever returning them. This is what we call quarrying, and it comes with a hefty environmental price tag.

Aggregate recycling offers a much smarter way forward. It’s like creating a library lending system where old, used books are brought back, spruced up, and put right back into circulation for the next person. This simple shift preserves the original collection while making sure everyone still gets the resources they need.

Why It Matters Now More Than Ever

Every project, whether it’s a small patio replacement in a Dorset garden or a huge commercial build, produces waste. Instead of just burying old concrete, bricks, and asphalt in a landfill, we can give them a second life. This is the very heart of the circular economy: moving away from a "take-make-dispose" mindset to one that keeps materials in use for as long as possible. You can dive deeper into how this works in our article on the circular economy in waste management.

The benefits of this approach are massive for everyone involved:

- Environmental Preservation: It dramatically cuts down on the need for new quarrying, which helps protect our natural landscapes and wildlife habitats.

- Cost Savings: Recycled aggregates are often cheaper than brand-new materials, helping to lower project costs for contractors and homeowners alike.

- Reduced Landfill Burden: It keeps millions of tonnes of heavy, bulky waste out of our already overflowing landfill sites.

- Lower Carbon Emissions: It generally takes far less energy to process recycled materials than it does to extract and transport virgin ones.

The UK is actually a world leader in this. An incredible 74.3 million tonnes of recycled and secondary aggregates were used across Great Britain in 2023, making up 31% of the country's total demand. This isn't just a niche practice; it's happening at a massive scale.

This isn't just a passing trend; it's a fundamental change in how we approach building. To see how recycled materials fit into the bigger picture, it's worth looking at the principles of Sustainable Design in Architecture. When we choose to recycle, we're not just putting up buildings—we're building a more responsible and resilient future.

From Demolition Debris to High-Quality Building Material

The journey from a pile of demolition rubble to a precisely graded, high-quality building material is a fascinating one. It’s a bit like a master chef who takes seemingly random leftover ingredients and transforms them into a refined dish. In the world of aggregate recycling, our raw ingredients are materials like broken concrete, old bricks, and used asphalt straight from construction sites.

Through a carefully organised process, this construction waste is reborn. It’s not just about smashing rocks; it’s a methodical system designed to recover valuable resources, ensuring the final product is clean, strong, and ready for a new life. This transformation involves several key stages, each playing a vital role in guaranteeing quality.

The process kicks off with careful collection and sorting. Waste materials are brought to a processing facility where they get an initial inspection. Here, large contaminants like timber, plastic, and scrap metal are pulled out to prevent damage to the machinery and to purify the raw material stream. This initial clean-up is absolutely crucial for the quality of the end product.

The Crushing and Screening Process

Once sorted, the material moves to the heart of the operation: the crushing stage. Powerful industrial crushers are the real workhorses of any recycling facility. These machines use immense force to break down large, unwieldy chunks of concrete and brick into smaller, more manageable pieces. The goal here is to create a consistent size that can be refined further.

Transforming demolition debris into high-quality building material often involves specialised machinery, and for larger projects, companies can explore options for crusher hire for demolition to manage this process on-site. This machinery is specifically designed to handle the tough, abrasive nature of construction waste.

After crushing, the aggregate moves onto a series of large vibrating screens. Just imagine them as giant, industrial-sized sieves. They separate the crushed material into different sizes, or ‘grades’, which are essential for different construction applications. For instance, larger pieces might be destined for sub-bases, while finer materials could be used for pipe bedding.

During the screening phase, even more purification happens. Advanced tech helps to separate any lingering unwanted materials from the aggregate, such as:

- Magnetic Separators: These powerful magnets pull out any remaining steel rebar or other ferrous metals from the crushed concrete.

- Air Classifiers: Think of these as powerful blowers. Jets of air are used to blow away lighter materials like paper, plastic, and wood fragments.

- Water Baths: Some processes even involve washing the aggregate to remove fine dust, silt, and other contaminants, resulting in an exceptionally clean product.

This meticulous separation ensures the recycled aggregate is free from impurities that could compromise its structural integrity.

Ensuring Quality and Consistency

The final step is all about quality control. The resulting piles of graded aggregate are tested to make sure they meet strict industry standards, like the WRAP Quality Protocol. This certification confirms that the material is no longer considered waste and is fit for its intended purpose, often performing just as well as brand-new, quarried aggregate.

By the end of this journey, what was once a pile of waste destined for landfill has become a valuable commodity. This high-quality recycled material is ready to be used in new driveways, building foundations, and road construction projects across Dorset and beyond.

This meticulous process builds real confidence in the recycling of aggregate, proving that sustainable materials can be reliable, cost-effective, and of exceptional quality. When managed correctly, debris from a dismantled building can become the strong foundation for a new one. For more information on managing specific materials like concrete, check out our guide on how to dispose of concrete responsibly.

Diverse Sources of Recycled Aggregates

The journey from waste to resource is fuelled by a surprisingly wide array of materials. When we talk about recycling aggregate, it’s easy to just picture a pile of broken concrete and bricks from a building site. And while those are certainly the heavyweights, the full picture is far richer.

It draws from various streams of our industrial and civic life. Understanding these sources is key to appreciating the scale of the UK's circular economy. It’s not just about what we knock down; it’s also about what we dig up, pave over, and even what’s left behind from industrial processes. Each one is a chance to reclaim value and rely less on new materials.

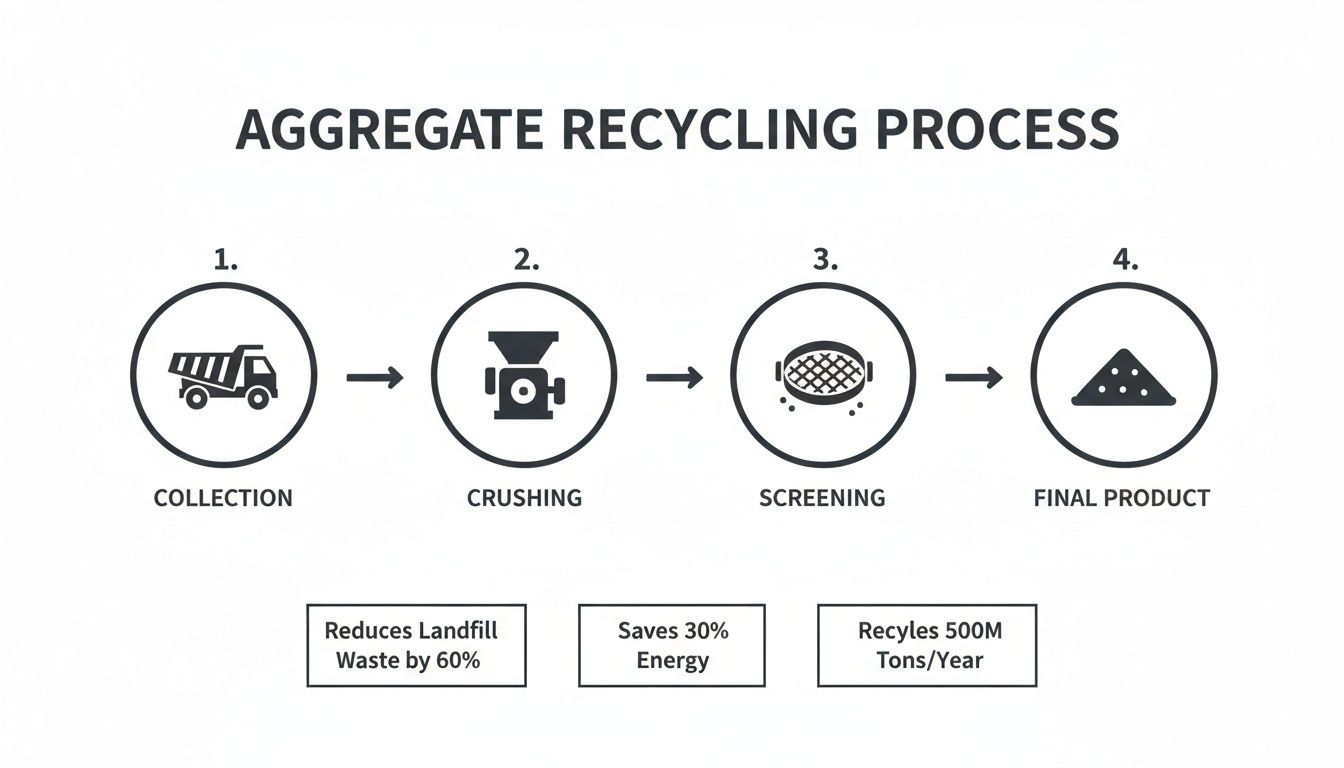

The infographic below shows the core stages of turning these varied materials into a uniform, high-quality product.

As you can see, no matter where the material starts its journey, the fundamental process of collection, crushing, and screening ensures a consistent and reliable final aggregate.

Construction and Demolition Waste

The biggest contributor, by a huge margin, is Construction, Demolition, and Excavation Waste (CDEW). This category is the absolute backbone of the aggregate recycling industry here in the UK.

Every time a building is demolished, a road is resurfaced, or foundations are dug, a huge amount of reusable material is created. We're talking about everything from concrete slabs and masonry blocks to asphalt and general rubble. These are perfect for recycling because they are inert, durable, and once processed, they have structural properties very similar to brand-new aggregates. This steady, high-volume supply makes CDEW the primary engine for recycled aggregate production.

The sheer volume is staggering. In 2022, CDEW generated 60.3 million tonnes of recycled aggregates, making it the largest single source of secondary materials in the country. You can explore detailed statistics on recycled aggregate volumes to see just how much of a contribution this makes to the circular economy.

Beyond the Building Site

While CDEW is the main player, other waste streams play a vital role, diversifying the supply and showing just how resourceful the industry can be.

-

Asphalt Planings: When roads are repaired or resurfaced, the old tarmac is scraped away. These "planings" aren't waste; they're a valuable resource. They can be reprocessed and folded into new asphalt mixes or used as a high-quality material for farm tracks, car parks, and hardstandings.

-

Industrial By-Products: A whole range of industrial processes produce materials that can be repurposed as aggregates. This includes slag from steel manufacturing, ash from incinerators (often called Incinerator Bottom Ash or IBA), and even leftovers from mining operations like China clay.

These alternative sources are crucial. They show a more joined-up approach to waste management, where by-products from one industry become essential raw materials for another. This kind of cross-sector teamwork is what makes the circular economy really work.

This table breaks down the primary sources of recycled and secondary aggregates in the UK, highlighting the significant contribution of each waste stream.

UK Recycled Aggregate Sources and Annual Contribution

| Material Source | Description | Annual Tonnes (2022) |

|---|---|---|

| CDEW | Concrete, bricks, rubble, and soil from construction and demolition. | 60.3 Million |

| Asphalt Planings | Reclaimed asphalt from road maintenance and repairs. | 5.8 Million |

| Industrial By-Products | Slag, ash, and other materials from industrial processes. | 7.4 Million |

By tapping into these varied sources, the industry ensures a resilient and steady supply of sustainable building materials for projects across Dorset and the entire UK.

Practical Applications for Recycled Aggregates

Once construction waste has been properly processed, it's transformed into a seriously versatile and high-quality product, ready for a new lease of life. The real magic of recycling of aggregate shines through in its huge range of real-world uses, helping everyone from weekend DIY-ers to major civil engineering firms.

This isn't just about finding a home for old rubble; it's about making a smart, sustainable choice for the job at hand. Think of it like a chef picking the right ingredients for a specific dish—different grades of recycled aggregate are suited to different tasks. By understanding what works where, you can make smarter, more cost-effective, and greener choices for your next project.

For Home and Garden Projects

For homeowners and landscapers across Dorset, recycled aggregates are a brilliant, budget-friendly alternative to digging up new materials from a quarry. They offer the same structural performance for countless garden and landscaping jobs, all while shrinking your project's environmental footprint.

You can put them to work on all sorts of tasks around the home:

- Creating a Solid Base: Recycled crushed concrete is the perfect sub-base for patios, garden sheds, driveways, and decking areas. It compacts brilliantly to create a stable foundation that’s built to last.

- Improving Drainage: Got a soggy patch in your garden? Coarser grades of recycled aggregate are excellent for creating soakaways or improving drainage, preventing soil from becoming compacted and helping your plants thrive.

- Building Garden Paths: A layer of recycled aggregate makes a fantastic, firm base for decorative gravel paths, making sure they stay level and sturdy for years.

- Backfilling and Levelling: It’s also an ideal material for backfilling trenches after you've laid pipes or for levelling out uneven ground before you lay new turf.

A classic example is using a Type 1 recycled aggregate—a mix of crushed concrete and brick—to create a solid base for a new driveway. It gives you the same load-bearing strength as its quarried equivalent but costs a lot less and has a much smaller environmental impact.

For Commercial and Construction Use

On a bigger scale, the construction industry now relies heavily on recycled aggregates to meet both project deadlines and sustainability goals. For professional contractors, these materials have become a cornerstone of modern, responsible building. Their use is widespread and absolutely vital for developing our infrastructure.

The applications in a commercial setting are extensive and often technically demanding, which really shows just how reliable and high-quality these recycled products are.

Key Construction Applications

The sheer versatility of recycled aggregates makes them a go-to for many large-scale projects:

- Road Construction: It’s widely used as a sub-base material for new roads, car parks, and pavements. Its excellent compaction properties create a stable, tough foundation that can handle heavy traffic with ease.

- Pipe Bedding: Finer grades of recycled aggregate provide a secure and protective bed for laying underground pipes and utilities, preventing damage from sharp stones or shifting ground.

- Bulk Fill: For major construction projects, recycled materials are used as bulk fill to raise ground levels or build embankments, offering a solution that’s both cost-effective and structurally sound.

- Component in New Concrete: Under strict quality controls, certain types of recycled aggregate can be mixed into new concrete for non-structural elements like kerbs, pavements, and blocks.

Local Case Study: Dorset Road Improvement

In a recent road improvement project in rural Dorset, a local contractor made the switch to recycled aggregate from The Waste Group for the entire sub-base of a new access road. By using over 500 tonnes of recycled crushed concrete sourced from a local demolition, the contractor didn't just save thousands of pounds. They also cut out dozens of lorry journeys that would have been needed to haul virgin materials from a distant quarry. It was a move that slashed the project's carbon footprint and showed a real commitment to the local circular economy.

When it comes to building materials, trust is non-negotiable. For contractors and developers, the environmental and cost-saving perks of recycled aggregate are great, but the real question is always about quality. Is the final product reliable, safe, and fully compliant?

Thankfully, this isn't some unregulated free-for-all where rubble is just crushed and dumped on-site. The recycled aggregate industry is underpinned by a solid framework of regulations and quality standards, making sure that what you're using is not just a sustainable choice, but a professionally sound one.

These standards are what give you peace of mind. They provide the assurance that the recycled materials for your project will meet the necessary specifications, ensuring structural integrity from the ground up. It’s how waste officially becomes a high-value product, ready for even the most demanding construction jobs.

The Gold Standard: The WRAP Quality Protocol

At the heart of quality assurance in the UK is the WRAP Quality Protocol for the Production of Aggregates from Inert Waste. Think of it as a detailed recipe book a chef must follow to the letter to earn a Michelin star. It sets out crystal-clear, end-of-waste criteria that producers have to meet.

When a supplier like The Waste Group follows these steps meticulously—from sourcing and sorting the raw materials to the final processing and testing—the aggregate produced is no longer legally classified as waste. This is a crucial distinction. It confirms the material is a high-quality product, fit for purpose, and performs just as well as its virgin counterparts in many applications.

This protocol creates a clear audit trail, giving customers the confidence that they are buying a certified, reliable material that meets all the necessary legal and technical requirements.

By adhering to the WRAP Quality Protocol, we ensure our recycled aggregates are not just "good enough," but are manufactured to a consistently high standard that professionals can depend on for their projects, from sub-bases to drainage systems.

Enhancing Transparency and Accountability

The industry is always pushing for better accountability, and a major change is just around the corner. A mandatory UK-wide digital waste tracking system is set to be introduced in 2025. This is a big deal, as it will massively improve the accuracy and availability of data on construction and demolition waste.

For businesses like ours in Dorset and across the UK, this improved data infrastructure means more reliable information for planning our operations and investing in the right recycling technology. You can learn more about how this will improve recycling data and infrastructure.

This digital system will create a level of transparency we’ve never seen before, allowing regulators and customers alike to track the journey of waste from its source to the final recycled product. It’s a huge step forward in building a truly accountable circular economy.

By choosing a supplier that embraces these regulations, you're not just ticking a compliance box for your project. You're actively supporting a system that champions quality, sustainability, and transparency in the recycling of aggregate.

Choosing The Waste Group for Your Aggregate Needs

Making a greener choice for your project shouldn’t be a hassle. Whether you’re a homeowner giving your garden a makeover or a contractor managing a huge construction site in Dorset, working aggregate recycling into your plans is a smart, simple move. It’s kinder to your wallet, better for the planet, and a great way to support the local circular economy.

At The Waste Group, we handle everything from start to finish. We don't just drop off high-quality recycled materials; we manage the entire loop, from collecting your concrete and brick waste to delivering premium recycled aggregates right back to your site. It’s a seamless approach that gives you total peace of mind.

Our services are designed to fit any project, big or small. With a quick phone call or a few clicks online, you can get everything sorted and start your sustainable building journey.

Our Straightforward Aggregate Services

We’ve kept our services as simple and flexible as they can be, covering both waste removal and material supply. This means you only need one partner for your entire project, which saves you a ton of time and coordination headaches.

Our core services include:

- Skip Hire: Perfect for smaller jobs, our skips make it easy to gather waste materials like old concrete, bricks, and soil for recycling.

- Grab Lorry Hire: For bigger demolition or excavation work, our grab lorries can quickly clear large volumes of waste, ready for processing at our local facility.

- Recycled Aggregate Supply: We deliver a range of top-quality recycled aggregates, like crushed concrete (6F2) and screened topsoil, directly where you need them.

The whole process is a breeze. You can get a quick quote, book your order, and schedule a delivery or collection that fits your timeline perfectly. This no-fuss system ensures your project keeps moving without any hold-ups.

The Clear Benefits of Partnering with Us

Choosing The Waste Group isn’t just about buying materials. It’s about partnering with a company that genuinely cares about sustainability, quality, and keeping customers happy. We take our role seriously, making sure every part of our service is up to scratch. Our fantastic 4.9-star reputation speaks for itself and shows our dedication to getting things right.

By choosing our recycled aggregates, you could see cost savings of up to 20% compared to buying brand new materials, while also slashing your project’s carbon footprint. For every tonne of aggregate recycled instead of quarried, you can save around 6 kg of CO2.

But it’s not just about the numbers. Our commitment to the environment is baked into everything we do. For every single skip hired from us, we plant a tree, directly helping with local reforestation efforts. It’s a small promise that adds up to a massive impact over time. When you work with us, you’re choosing a service that’s not only fully compliant with all waste regulations but is also actively working to create a greener Dorset.

To see our full range and find the perfect sustainable materials for your next project, learn more about the high-quality aggregates we supply.

Frequently Asked Questions About Aggregate Recycling

Even after getting the rundown on aggregate recycling, it's totally natural to have a few questions about how it all works in practice. Whether you're a homeowner planning a new patio or a contractor managing a major build, we've got you covered.

Let's clear up any lingering doubts. Here are the most common queries we get, with straightforward answers to help you choose sustainable materials with confidence.

Is Recycled Aggregate as Strong as New Aggregate?

Yes, absolutely. When you get it from a reputable supplier who follows the rules, high-quality recycled aggregate is just as strong and reliable as the freshly quarried stuff for most jobs. This isn't just about smashing up old concrete; it’s a proper manufacturing process.

The material goes through some serious crushing, screening, and cleaning to make sure it meets very specific standards for size and purity.

For many common uses, like creating a solid sub-base for a road, driveway, or building foundation, the performance of certified recycled aggregate is directly comparable to virgin materials. The WRAP Quality Protocol provides the official framework that guarantees this quality, confirming the material is fit for purpose.

This certification means you can have complete confidence in its strength and durability, making it a smart and dependable choice.

What Home Projects Can I Use It For?

Recycled aggregates are brilliant for all sorts of home and garden projects here in Dorset. They're a fantastic, budget-friendly way to get professional results while doing your bit for the environment.

They're the perfect choice for any task that needs a solid foundation or good drainage. Think about using them for:

- Creating a solid base for sheds, patios, and driveways.

- Building sturdy garden paths that won't get wobbly over time.

- Improving drainage in those soggy patches of your lawn or flowerbeds.

- Filling trenches after you've laid new pipes or cables.

Our crushed concrete (6F2), for instance, is ideal for sub-bases, while our screened topsoil is perfect for landscaping or getting ready for new turf. Using these materials not only saves you a bit of cash but also massively reduces your project's carbon footprint.

How Does It Actually Help the Environment?

This is one of the best reasons to go for recycled aggregates. The positive impact is huge and creates a ripple effect that helps our local environment and the construction industry as a whole.

First off, it keeps millions of tonnes of heavy, bulky waste from being dumped in landfill sites. Instead of just sitting there for centuries, it gets a new life.

It also dramatically cuts down on the need to quarry for new stone, sand, and gravel. This helps preserve our beautiful natural landscapes, protect wildlife habitats, and saves these finite resources for the future. Plus, the whole recycling process uses a lot less energy than digging up and hauling new materials, which means a direct cut in carbon emissions.

How Do I Arrange Waste Collection and Aggregate Delivery?

We've made this part as simple as possible at The Waste Group. If you're creating waste like concrete, bricks, or rubble from your project, you can just hire one of our skips or a grab lorry for a quick and easy collection.

We'll take that waste to our local facility, where it gets processed into top-quality recycled aggregates.

When you're ready for your materials, just give us a call or use our simple online ordering system. We offer reliable and flexible delivery across Dorset, bringing exactly what you need right to your door or site. It's a seamless service that makes it easy to handle both your waste disposal and material supplies in one go.

Ready to make a sustainable choice for your next project? The Waste Group offers high-quality recycled aggregates, reliable skip hire, and expert advice to help you succeed. Get in touch with our team today to discuss your needs and get a competitive quote.