A Practical Guide to Recycling of Aggregates

A Practical Guide to Recycling of Aggregates

Recycling aggregates is all about taking old construction and demolition waste and turning it into something new and useful. Think of it as giving old concrete, asphalt, and bricks a second life. Instead of just burying them in a landfill, we crush and screen them to create high-quality materials for new projects. It’s a smart, sustainable approach that’s become a cornerstone of modern construction.

Building a Circular Future with Recycled Aggregates

What if buildings and roads didn't just reach a dead end in a landfill? Imagine a system where, once they've served their purpose, their core components are reclaimed, reprocessed, and put back to work. This isn't a futuristic dream; it's the reality of aggregate recycling, a vital practice that turns waste streams into resource streams.

At its core, this whole process is a perfect example of the circular economy in action. We’re moving away from the old linear model of "take, make, and throw away." By recycling aggregates, we close the loop, making sure that the huge amount of material from construction, demolition, and excavation finds its way back into the supply chain. This isn't just about ticking an eco-friendly box; it's about building a tougher and more efficient industry.

The Foundation of a Sustainable Approach

The journey from a pile of rubble to a certified building product is a careful one. It’s about taking what looks like worthless debris and transforming it into precisely engineered materials that meet strict quality and performance standards. This guide will walk you through that entire journey, breaking down each step.

Here’s what we’ll cover:

- The raw materials that are used to create recycled aggregates.

- The step-by-step process of turning that waste into a valuable product.

- The huge environmental and financial benefits that make it so compelling.

- The quality checks that guarantee these materials are safe and reliable.

By getting to grips with how this works, you'll see how we can build a more resourceful future for construction. The move towards recycled materials isn't just a passing trend—it's a necessary step forward. By getting on board, you're contributing to a healthier planet and a smarter economy. For companies looking to champion this change, there are even dedicated funding options, like various grants for waste prevention, to help get things started.

Using recycled aggregates is a powerful move. It shows a real commitment to shrinking a project's environmental footprint while also delivering serious cost savings—proving that sustainability and profitability can absolutely go hand-in-hand.

This mindset is central to building responsibly today. When we choose recycled materials, we don't just conserve finite resources like sand and gravel; we also cut down on the energy and carbon emissions that come from quarrying and transporting new materials. You can see how this fits into the bigger picture in our guide on the circular economy in waste management. It’s a crucial shift towards building a truly circular future.

What Are Recycled Aggregates Really Made Of?

To really get your head around aggregate recycling, you have to look beyond the finished pile of crushed stone and understand its origin story. Where does it all come from?

Picture a demolition site. It’s often a messy scene of broken concrete, mangled rebar, and heaps of old bricks. But this isn't just rubbish waiting for the tip. It's the raw, untapped potential for a whole new generation of building materials.

The journey starts with what's known in the trade as Construction, Demolition, and Excavation Waste (CDEW). This is a catch-all term for everything from old roads and dismantled buildings to the soil and rock dug out from a new foundation. Instead of being buried in a landfill, this material is carefully gathered up and taken to a recycling facility. That's where the real magic begins.

From Rubble to Resource: The Primary Sources

The main ingredients for recycled aggregates come from the very stuff our towns and cities are built from. When a building or road gets old and needs replacing, its components become the primary feedstock for the recycling process. For a closer look at how this material is first recovered, it's worth understanding the work of specialist demolition excavation services.

So, what are we actually talking about? Let's break down the common sources and the types of aggregates they become.

Common Sources and Types of Recycled Aggregates

This table shows the primary waste materials that are transformed into valuable, reusable aggregates.

| Source Material | Common Examples | Resulting Aggregate Type |

|---|---|---|

| Concrete | Demolished buildings, old pavements, foundations | Crushed Concrete (Type 1, 6F2) |

| Asphalt | Milled road surfaces, old car parks | Reclaimed Asphalt Pavement (RAP) |

| Brick & Masonry | Demolished walls, old structures | Crushed Brick, Mixed Rubble |

| Excavation Spoil | Soil, clay, rock from groundworks | Screened Soil, Fill Material |

It’s crucial to understand these materials aren’t just scooped up and dumped on another site. They go through a meticulous process of sorting, crushing, and screening to get rid of contaminants like wood, metal, and plastic. What comes out the other side is a clean, precisely graded product engineered to meet strict performance standards.

Recycled aggregates aren't a second-best option; they are properly manufactured products. Through careful processing, a heap of rubble is transformed into a certified material that can often outperform virgin stone in certain jobs.

This whole transformation shows just how clever modern engineering has become. What was once seen as debris is now a high-quality building block, ready for its next chapter.

Don't Forget Secondary Aggregates

Beyond the direct recycling of CDEW, there’s another important player: secondary aggregates. These don't come from old construction sites. Instead, they are useful by-products from other industrial processes. Think of them as bonus materials that would otherwise be wasted.

For instance, making steel creates blast furnace slag, a tough, rock-like material that’s brilliant for road building and concrete. In the same way, incinerator bottom ash from waste-to-energy plants can be processed into a handy aggregate. These sources help broaden the sustainable supply chain, meaning we have to dig less out of the ground.

The impact of using both recycled and secondary aggregates is massive. In 2023, they accounted for 31% (or 74.3 million tonnes) of the UK's entire aggregate demand. This impressive figure, highlighted by the Mineral Products Association, means that nearly a third of all aggregates used in UK construction came from sources that used to be considered waste.

This shift is a clear sign of a real commitment to using resources more efficiently. By embracing both recycled and secondary sources, the construction industry is building a smarter, more sustainable future. You can check out the wide range of quality recycled aggregates we offer that are all part of this circular economy.

The Aggregate Recycling Process Explained Step by Step

Turning a jumbled pile of rubble from a demolition site into a certified, high-quality construction material isn't just a case of smashing it up and hoping for the best. It’s a surprisingly sophisticated process. Think of it less like a scrapyard and more like a high-tech refinery, where raw ingredients are meticulously cleaned, sorted, and graded to create a reliable and consistent final product.

Every stage is designed to purify the material and shape it to exact specifications. This is how recycled aggregate doesn't just meet but often exceeds the standards needed for modern construction. Let's walk through how it's done, from the moment waste leaves the site to its final certification.

Step 1: Collection and Transportation

It all starts at the source—a demolition site, a road being resurfaced, or a major excavation. Here, raw materials, collectively known as Construction, Demolition, and Excavation Waste (CDEW), are loaded onto tipper trucks or grab lorries.

This isn't just about haulage; it’s the first vital link in a chain of custody. Getting the material from A to B without contamination is crucial for ensuring a steady, clean flow of feedstock to the recycling facility.

Step 2: Sorting and Contaminant Removal

As soon as the CDEW arrives at the plant, it gets its first major check-up. This is the sorting phase, where we weed out all the unwanted stuff. It’s a make-or-break moment, as the purity of the final product hinges on how well this initial separation goes. Getting it right on-site with good construction site waste segregation can make this part of the job much smoother.

Using a combination of machines and a hands-on approach from our team, we pull out all sorts of impurities:

- Wood and Plastics: These lightweight materials are a no-go, as they can weaken the structural integrity of the final aggregate.

- Metals: Powerful magnets are used to yank out reinforcing bars (rebar), old pipes, and any other metallic odds and ends.

- Soil and Fines: Excess dirt and fine particles get screened out to make sure the aggregate has the right composition.

- Other Debris: Anything else that isn't mineral-based is removed to leave a clean feedstock for the crushers.

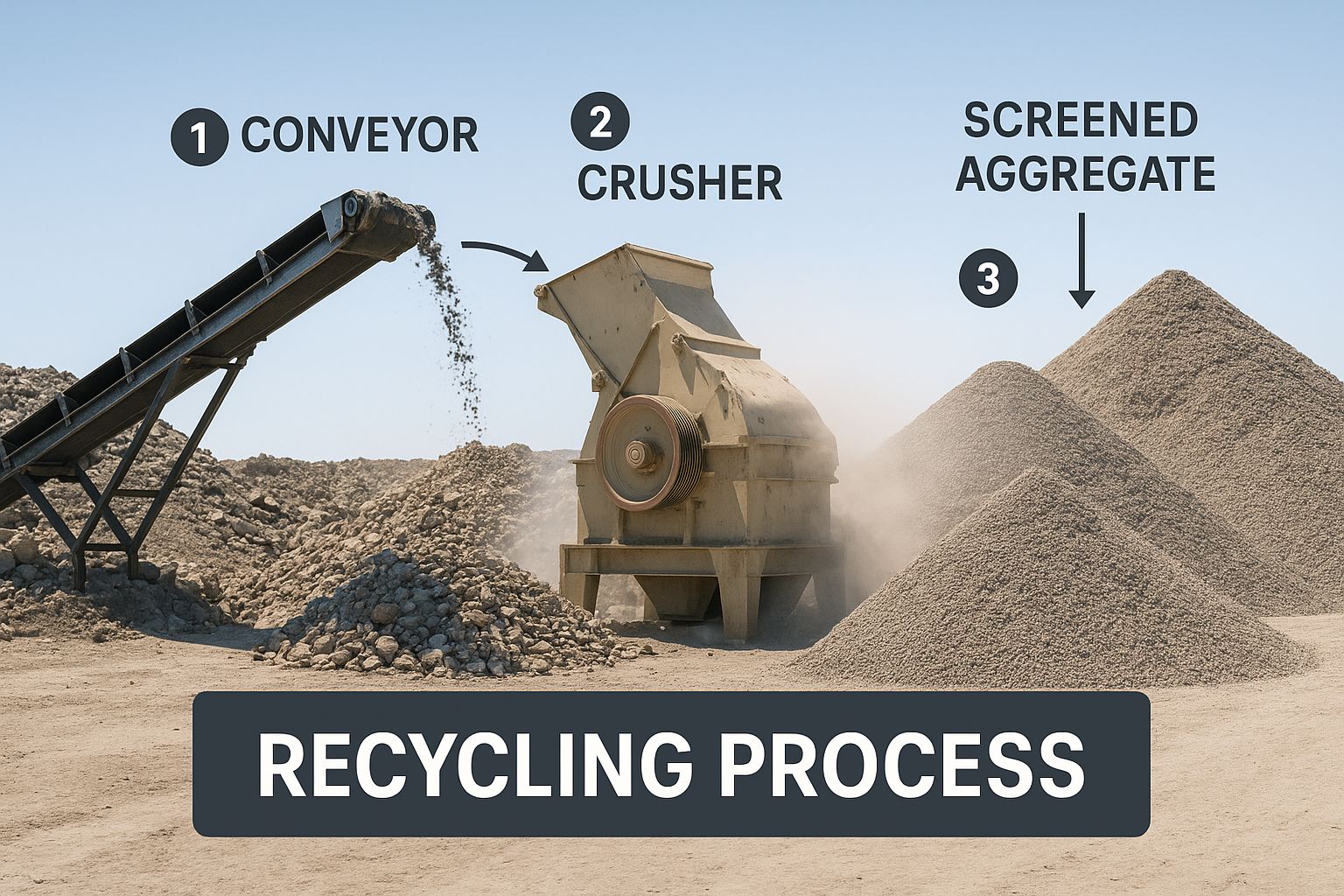

This infographic gives you a great visual of how waste journeys through a recycling facility.

It shows how each distinct process—from sorting and crushing to screening—works in sequence to transform construction waste into valuable, reusable materials.

Step 3: Crushing and Pulverising

With the contaminants gone, the clean concrete, brick, and asphalt are fed into the real workhorses of the operation: the crushers. These powerful machines use immense force to break down big, awkward chunks into much smaller, uniform pieces.

The main goal here is simply size reduction. A primary crusher does the initial heavy lifting, and the material might then move through secondary or even tertiary crushers for more refinement. This pulverising step is what creates the granular base needed for the final products.

Step 4: Screening and Grading

After being crushed, the material is just a big mix of different-sized pieces. The screening stage is where we bring order to this chaos. The aggregate is sent across a series of huge, vibrating screens—basically industrial-sized sieves with different mesh sizes.

This is where a pile of crushed rubble becomes a marketable product. By separating the aggregate into specific sizes, we can produce certified materials like Type 1 MOT for road sub-bases or finer grades for things like pipe bedding and drainage.

Each screen lets smaller particles drop through while holding back the larger ones. This neatly sorts the aggregate into different stockpiles based on size, a level of precision that allows recycled materials to meet strict engineering specifications. In fact, the UK construction sector is a world leader here, recovering and reusing a staggering 60.3 million tonnes of CDEW in 2022 alone.

Step 5: Quality Testing and Certification

The last step is all about building confidence. Before any recycled aggregate heads out the gate, it undergoes rigorous quality checks. We take samples from the stockpiles and send them to the lab to be analysed for key properties:

- Particle Size Distribution: Making sure the grade is consistent.

- Strength and Durability: Testing its ability to handle heavy loads.

- Contaminant Levels: One final check to guarantee purity.

Only when it passes these tests can the material be certified under frameworks like the WRAP Quality Protocol. This certification confirms it's a high-quality product, not waste. It’s this meticulous process that ensures every tonne of recycled aggregate is fit for purpose, ready to start a new life in another project and support a truly circular economy.

Key Benefits of Using Recycled Aggregates

Opting for recycled aggregates is much more than a simple tick-box for sustainability. It's a savvy move that brings real, tangible benefits to your project's budget and the environment. The recycling of aggregates proves that you don't have to choose between responsible construction and commercial sense—they can, and should, go hand-in-hand.

When we stop relying so heavily on freshly quarried materials, we take a huge amount of pressure off our natural landscapes and create a far more robust supply chain. Let's dig into the specific environmental and economic advantages that make recycled materials a no-brainer for modern construction.

Boosting Environmental Performance

Every single tonne of recycled aggregate you use makes a direct, positive environmental impact. Instead of being dumped in a landfill, old concrete, brick, and asphalt are given a new lease of life as valuable resources.

One of the biggest wins is the conservation of our natural resources. By swapping virgin stone for a recycled alternative, we cut down the need for quarrying. That means less damage to wildlife habitats, lower energy use from heavy extraction machinery, and preserving our finite geological assets for the future.

It also helps tackle the ever-growing problem of landfill space. Construction and demolition waste is notoriously bulky. Diverting this material from landfill doesn't just save precious space; it helps avoid the long-term environmental headaches that come with burying waste.

And then there's the carbon footprint. Think about the journey of virgin aggregates for a moment. They're often dug out of the ground in remote locations and hauled hundreds of miles to site. Recycled aggregates, on the other hand, are usually processed much closer to the urban areas where construction happens, which drastically slashes fuel consumption and the associated CO2 emissions.

Choosing recycled aggregates means you're actively supporting a circular economy. It's a simple change that conserves natural stone, cuts transport emissions, and keeps millions of tonnes of perfectly good material out of our overflowing landfills.

Achieving Significant Economic Gains

The environmental case is strong, but the financial arguments for recycled aggregates are just as convincing. For any project manager, keeping costs in check without sacrificing quality is the name of the game, and this is where recycled materials really deliver.

The most obvious saving is the upfront cost. Recycled aggregates are generally more cost-effective than their quarried equivalents. This can lead to huge savings on material procurement, especially for large-scale projects that need vast quantities of sub-base or fill material.

Another major cost saving comes from avoiding disposal fees. The Landfill Tax is a hefty expense for any project producing waste. By recycling materials either on-site or at a dedicated facility, you can sidestep these charges completely.

Gaining a Competitive and Strategic Edge

Beyond the immediate cost benefits, using recycled aggregates gives you a real strategic advantage. In an industry where sustainability is becoming more and more important, showing a genuine commitment to greener practices can make your business stand out from the crowd.

Using recycled materials can help you secure valuable points for certifications like BREEAM (Building Research Establishment Environmental Assessment Method). These credentials are often a key requirement for public sector contracts and a big plus for private clients.

- Enhanced Company Reputation: It bolsters your green credentials, making you more attractive to eco-conscious clients and investors.

- Competitive Tendering: A solid sustainability policy can give you the edge you need when bidding for new work.

- Future-Proofing Your Business: As environmental regulations inevitably get stricter, getting on board with circular economy principles now sets your company up for long-term success.

At the end of the day, the recycling of aggregates isn't just an environmental duty; it's a smart business decision. It enables you to deliver high-quality projects more affordably while building a reputation as a responsible, forward-thinking contractor. Protecting the planet while boosting your bottom line makes recycled aggregates an essential part of modern construction.

Common Applications for Recycled Aggregates

The real beauty of recycling aggregates is just how versatile they are. Far from being some niche, eco-friendly gimmick, these materials are the unsung heroes of countless construction projects. They’re providing the strength, stability, and sheer reliability needed for everything from major motorways to garden paths.

This isn’t about just chucking it in as backfill to save a few quid. Certified recycled aggregates are properly engineered products, trusted across a huge range of demanding jobs. Their consistent quality and performance have shown time and again they are more than a match for virgin materials.

Sub-Base and Bulk Fill Applications

One of the biggest and most common uses for recycled aggregates is in creating a rock-solid foundation for roads, buildings, and car parks. Just think of it as the strong, stable platform that everything else is built on.

For this kind of work, a product like Type 1 MOT is the go-to industry standard. Traditionally, this would be quarried granite or limestone, but the recycled equivalent is produced from high-quality crushed concrete. This material is meticulously graded to make sure it compacts tightly, giving you a robust, load-bearing sub-base that stops any settlement over time.

In the same way, recycled aggregates are perfect for bulk fill. This is when you need to raise ground levels or fill in large voids where huge quantities of material are needed. Using recycled options here brings massive cost savings and environmental benefits, all without cutting corners on structural integrity.

Recycled aggregates are not a compromise on quality; they are a mark of smart, efficient construction. By meeting rigorous standards like Type 1 MOT, materials derived from crushed concrete and asphalt are proven to deliver the same structural performance as their quarried counterparts.

Drainage Systems and Pipe Bedding

Getting water management right is critical on any construction site, and this is another area where recycled aggregates really shine. Because of their specific particle sizes, they create voids that let water pass through freely, which prevents waterlogging and protects structures.

For this reason, they are an excellent choice for:

- Pipe Bedding: Surrounding underground pipes with a stable, permeable layer. This protects them from damage and allows for drainage.

- French Drains: Creating subsurface channels that cleverly collect and redirect groundwater away from foundations.

- Soakaways: Building underground structures designed to manage surface water runoff by allowing it to slowly seep back into the ground.

Using a clean, graded recycled aggregate ensures that these drainage systems do their job properly for years to come, managing water in an effective and sustainable way.

New Concrete and Asphalt Mixes

The innovation in the recycling of aggregates now even extends to creating brand-new construction materials. Reclaimed Asphalt Pavement (RAP) is a fantastic example of this. Old road surfaces are milled up, processed, and then mixed back into new hot mix asphalt.

This is a perfect example of a closed-loop system in action. It cuts down the need for new bitumen and virgin aggregate, which in turn lowers costs and massively reduces the carbon footprint of road construction.

Similarly, certain grades of crushed concrete can be used as a partial substitute for virgin coarse aggregate in new concrete mixes. While this is often kept to non-structural applications for now, it just shows the ongoing push to maximise the reuse of these valuable materials. From the foundations under your feet to the road you drive on, recycled aggregates are proving their worth.

Navigating UK Quality Standards and Compliance

Let’s be honest, in the construction world, using a dodgy material is simply not an option. Your reputation and the safety of your project are on the line. That's where quality standards and compliance come in – they're the rulebook that guarantees the recycled aggregates you're using are up to the job.

These aren't just vague guidelines. They are rigorous, legally-binding frameworks that ensure every single tonne of recycled material is a properly engineered product, not just a pile of waste. This gives everyone, from the architect drawing up the plans to the contractor on the ground, total confidence in the recycling of aggregates.

The WRAP Quality Protocol: From Waste to Product

A huge piece of the puzzle is the WRAP (Waste & Resources Action Programme) Quality Protocol. Think of it as the official process that transforms a material's legal status. It sets out the exact point at which recycled aggregate stops being classified as 'waste' and can be sold as a high-quality product.

To earn this classification, producers have to prove their material meets a strict set of criteria. This involves having a solid quality management system in place, carrying out regular tests, and making sure the aggregate is fit for its intended purpose. When you buy aggregate that meets this protocol, you know it's been thoroughly vetted and is ready to use without needing extra waste management controls.

The WRAP Quality Protocol provides a clear, legally recognised path from waste to product. It's the official stamp of approval that tells you the recycled aggregate you’re buying is safe, high-quality, and fully compliant with UK environmental regulations.

This certification is absolutely critical. It means the material can be bought, sold, and used with the same level of trust as brand-new quarried materials, making the whole supply chain transparent and reliable.

Getting Technical with British and European Standards

Beyond the WRAP protocol, recycled aggregates also have to meet the nitty-gritty technical specs laid out in British Standards (BS) and their European equivalents (BS EN). These standards get right down to the details, outlining the physical properties a material must have to perform correctly in different construction jobs.

For instance, a key standard you'll often see is BS EN 13242. This covers aggregates used for unbound and hydraulically bound materials in civil engineering and road building. It sets out very precise limits on things like:

- Particle Size Distribution: This ensures the aggregate has the right mix of sizes to compact properly and create a stable base.

- Material Composition: It strictly limits the amount of unwanted stuff like wood, plastic, or plasterboard that could compromise performance.

- Strength and Durability: The aggregate is tested to see how it stands up to heavy loads and the good old British weather.

When a supplier gives you the paperwork showing their product meets these standards, it's not just a piece of paper – it's a guarantee of its physical performance. It’s your proof that the material has been properly tested and is fit for purpose, whether you're laying a road sub-base or a drainage system. This unwavering commitment to standards is what makes the recycling of aggregates a professional and dependable choice for modern construction.

Answering Your Questions About Recycled Aggregates

Even with all the clear benefits, it's completely normal to have a few questions before you fully switch over to recycled aggregates. You want to be sure about the quality, where you can use them, and what it means for your budget. That's smart.

Let's clear up some of the most common queries. The truth is, the recycling of aggregates isn't a new-fangled idea; it’s a mature and highly regulated process that produces materials you can absolutely depend on.

Are Recycled Aggregates as Strong as New Ones?

This is usually the first question on everyone's mind, and the answer is a straightforward 'yes'. Recycled aggregates aren't just crushed-up rubble. They're properly engineered products that go through strict quality control.

To be sold, they have to meet the exact same tough British and European standards (BS EN specifications) as materials dug straight from a quarry. They must comply with protocols like the WRAP Quality Protocol, which means regular lab testing for strength, composition, and durability. So, for something like a road sub-base, a recycled Type 1 MOT has the same structural integrity as one made from quarried stone, because it's been tested and certified to meet that precise standard.

The strength of a recycled aggregate isn't a matter of opinion; it's a matter of certification. When a product meets established industry standards, its performance is guaranteed, regardless of whether its origin is a quarry or a demolition site.

Can They Be Used in Any Construction Project?

While they're incredibly versatile, they aren't a one-size-fits-all solution for every single job. It all comes down to the technical needs of the project. For a huge range of common applications, they are the perfect choice, often meeting or even exceeding performance requirements.

This includes things like:

- Sub-bases and bulk fill: The go-to for roads, car parks, and foundations.

- Drainage media: Fantastic for French drains, soakaways, and bedding for pipes.

- Piling mats and haul roads: Creating a stable, solid surface for heavy machinery.

However, for some very specific uses, like architectural concrete where a certain look is essential, virgin materials might still be specified. The key is simply to match the right certified product to the right job.

How Will They Impact My Project's Budget?

This is where recycled aggregates really shine. Using them has a major, positive impact on your project's bottom line, and the savings come from two different places. First off, the material itself is often cheaper to buy than quarried stone.

Secondly, you get to sidestep the hefty costs of waste disposal. Tipping construction waste at a landfill comes with a significant Landfill Tax. But by embracing the recycling of aggregates, you turn what was a costly waste problem into a valuable resource. This double saving—on buying materials and on waste disposal—directly cuts your project expenses without cutting any corners on quality.

Ready to build sustainably without breaking the bank? The Waste Group provides high-quality, certified recycled aggregates for projects of all sizes. Learn more and get a quote at https://www.thewastegroup.co.uk.