Recycling of glass bottles: A practical guide to smarter waste management

Recycling of glass bottles: A practical guide to smarter waste management

Recycling glass bottles is more than just a good habit—it’s a surprisingly effective way to save energy, look after our natural resources, and cut down on carbon emissions. In fact, recycling a single glass bottle saves enough energy to power a laptop for 25 minutes. It’s a small action that makes a real environmental difference and is central to building a sustainable, circular economy.

The Real Impact of Recycling Glass Bottles

Before we get into the nuts and bolts of how glass is recycled, it’s worth understanding why it’s so important. The benefits go far beyond just freeing up space in your bins; they create a positive ripple effect that helps both our environment and our economy.

At its heart, recycling glass bottles is all about creating a circular economy. Unlike the old "take-make-dispose" model, a circular system keeps materials in use for as long as possible. Glass is the perfect material for this because it can be recycled over and over again without ever losing its quality or purity.

Preserving Natural Resources

Making a brand-new glass bottle means digging up raw materials like sand, soda ash, and limestone. While we might think these are plentiful, quarrying them scars landscapes and uses a huge amount of energy. For every tonne of glass we recycle, we save over a tonne of these natural materials.

By making glass bottle recycling a priority, we directly reduce the strain on the planet’s finite resources. Every bottle you pop in the recycling is one less that has to be made from scratch, which helps preserve natural habitats for the future.

This is a really tangible way to shrink our collective environmental footprint, one bottle at a time. The more you learn about the environmental impact of landfills, the clearer the benefits of recycling become.

Significant Energy and Emission Reductions

The energy savings are probably the most impressive part of the story. Manufacturing glass from raw materials is incredibly energy-hungry, as furnaces have to reach blistering temperatures to get the job done.

Recycled glass, known as cullet, has a much lower melting point. This simple difference leads to some massive energy savings. Here’s a quick look at the advantages:

- Lower Energy Consumption: Using cullet can slash the energy needed for manufacturing by as much as 30%.

- Reduced Carbon Emissions: For every tonne of glass that gets recycled, we stop almost a tonne of CO2 from being released into the atmosphere.

- Less Air and Water Pollution: Making glass from recycled materials also produces far less air and water pollution compared to using virgin materials.

It's clear that recycling glass isn't just a tidy waste management tactic; it's a direct action we can all take to combat climate change and protect our environment.

The Journey From Bin to New Bottle

Once you've dropped a glass bottle into your recycling bin, you've kicked off a brilliant process that turns old waste back into a valuable resource. It’s less like throwing something away and more like sending an ingredient back to the kitchen to be used in a brand-new recipe. This journey, from your kerbside bin back to the supermarket shelf, is a perfect example of a closed-loop system in action.

The whole procedure is a highly organised sequence of events, fine-tuned to capture as much value from your old glass as possible. It starts the moment a collection lorry arrives to pick up your recyclables, beginning a multi-stage journey at a specialised facility.

Stage 1: Collection and Initial Sorting

The first step is simply getting all that glass from thousands of homes and businesses to one central hub. This collected material is ferried over to a Material Recovery Facility (MRF), which is basically a giant sorting office for all sorts of recyclables.

Upon arrival, the mixed jumble of materials gets loaded onto conveyor belts. The immediate goal is to separate the glass from other items like plastic, paper, and metal that have found their way into the mix. This first pass often involves a combination of human sorters and automated machinery.

Think of the MRF as a bustling, efficient kitchen. A chef has to separate all the vegetables, proteins, and grains before starting to cook. Getting the ingredients right from the very beginning is crucial for the quality of the final dish.

This preliminary sorting stage makes sure that large contaminants are weeded out early on, getting the glass ready for the more detailed processing that follows.

Stage 2: Advanced Cleaning and Colour Separation

With the bulk of other materials now gone, the focus shifts to purifying the glass itself. The stream of glass travels through a series of advanced machines designed to remove those smaller, trickier contaminants.

Powerful magnets snatch out any stray metal caps or lids, while jets of air blow away light materials like paper labels and plastic sleeves. The glass is then often washed to get rid of food residue and other grime, ensuring it's as clean as possible for the next vital step.

Next, the glass is sorted by colour—usually into clear (flint), brown (amber), and green. This is absolutely critical because glass keeps its colour when melted down. To make a new clear bottle, you need clear glass; mixing colours produces a lower-grade, often murky-coloured product. This separation is done using sophisticated optical scanners that can identify and split the different colours with incredible speed and accuracy.

Stage 3: Creating the Key Ingredient: Cullet

After being thoroughly cleaned and sorted by colour, the glass bottles and jars are ready to be turned into their most useful form for recycling. The glass is fed into a crusher, which safely smashes it down into small, easy-to-handle pieces.

These pieces are then crushed even further into a sand-like substance known as cullet. Cullet is the magic ingredient, the primary raw material used to manufacture new glass containers. It’s far more efficient to melt cullet than it is to create glass from scratch using virgin raw materials like sand and limestone.

Producing high-quality cullet is the ultimate goal of the sorting process, as its purity has a direct impact on the quality of the new glass products made from it.

Stage 4: Remelting and Rebirth

The final stage is where the transformation really happens. The prepared cullet is taken to a glass manufacturing plant and mixed with a small amount of raw materials to get the chemical consistency just right. This mixture is then poured into a furnace and heated to over 1,500°C.

Because cullet melts at a lower temperature than raw materials, this process uses a lot less energy and produces fewer carbon emissions. Once it’s molten, the liquid glass is moulded into new bottles and jars, ready to be filled and sent right back to the shop shelves.

This cycle is remarkably quick and efficient. In the UK, we now recycle over 76% of all glass packaging, and a bottle can travel from your bin back to a store shelf in as little as 30 days. This rapid turnaround shows a real national commitment to sustainable waste management. To truly cut down on waste, it's also worth looking into creative upcycling ideas for old items that might otherwise end up in the bin.

Understanding Your Role in Glass Collection

The life of a recycled glass bottle doesn’t start at a processing plant or on the back of a lorry. It starts with you. Whether at home or in your business, the simple act of putting a bottle in the right place is the first, crucial link in the chain, directly shaping how successful the entire recycling process will be.

Getting to grips with the different collection methods available in the UK is the key to playing your part. From a household managing its weekly waste to a restaurant owner dealing with hundreds of bottles, there’s a system designed to fit.

Kerbside Recycling For Homeowners

For most of us, kerbside recycling is the most familiar way to handle our glass. Local councils provide dedicated bins or boxes for recyclables, which they collect right from our doorsteps on a regular basis. It's designed to be as straightforward as possible to encourage everyone to get involved.

The biggest plus is just how easy it is; no need to stockpile bottles or make a special trip. But it's vital to follow your local council’s rules. What’s accepted can vary quite a bit from one area to another, so your attention to detail really does count.

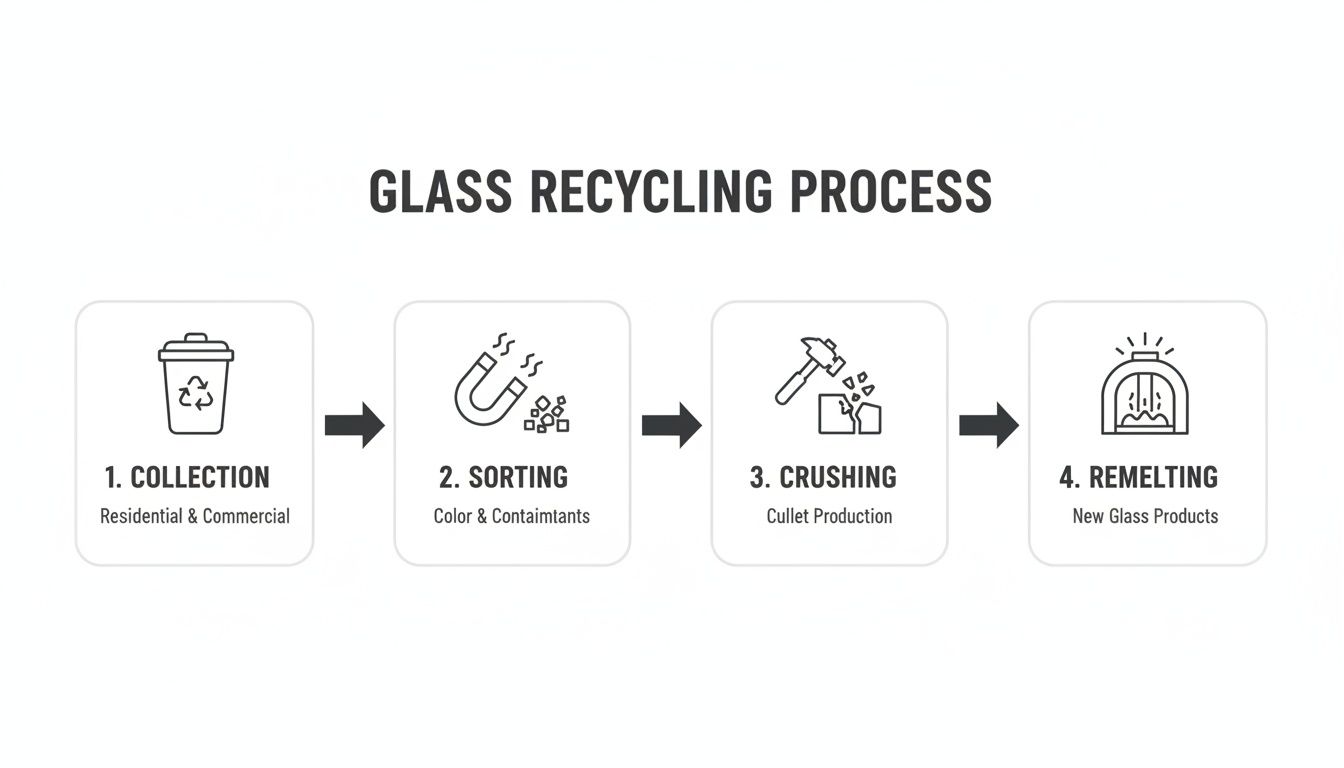

This diagram shows the simple but essential journey a glass bottle takes after it leaves your kerb, from sorting and crushing to becoming a brand-new product.

You can see how each stage builds on the last, which is why starting with clean, uncontaminated glass is fundamental to creating high-quality new items.

Community Bottle Banks

We’ve all seen them. Bottle banks are those large, colour-coded containers often found in supermarket car parks and at local recycling centres. They’re a fantastic option if your kerbside service doesn't take glass, or if you simply have more bottles than your bin can handle.

These banks usually ask you to separate your glass by colour – green, brown, and clear. This little bit of pre-sorting you do at the collection point is incredibly helpful because it results in a much purer stream of recycled material down the line.

By taking a few moments to sort your glass into the correct bottle bank, you're essentially doing the first step of the industrial process yourself. This simple action significantly boosts the purity of the final cullet and helps create a much more efficient closed-loop system.

They might require a little more effort than popping a bottle in your kerbside bin, but bottle banks are a highly effective way to recycle glass responsibly.

Commercial Glass Collection For Businesses

It goes without saying that businesses like pubs, restaurants, and hotels get through a much greater volume of glass than the average household. For them, a standard kerbside service just won’t cut it. This is where dedicated commercial collection services are absolutely essential.

These services provide specialist bins and arrange collections tailored to a business’s needs, ensuring all that glass is managed safely, legally, and efficiently. A key part of setting this up involves choosing the right waste recycle bin to handle the specific volume and type of waste being produced.

Comparison of Glass Collection Methods in the UK

To make it clearer, here’s a quick breakdown of how the different systems stack up for various users across the country.

| Collection Method | Primary User | Convenience Level | Key Consideration |

|---|---|---|---|

| Kerbside Collection | Homeowners | High | You must follow your local council's specific rules on what is accepted. |

| Bottle Banks | Community Members | Medium | Requires travel but allows for high-quality colour sorting at the source. |

| Commercial Services | Businesses | High | Offers tailored solutions for large volumes and ensures legal compliance. |

Ultimately, whether you're rinsing a single jam jar at home or arranging a large-scale collection for your pub, your participation is what fuels the entire glass recycling journey. Each method plays its own distinct role, but they all share the same goal: keeping valuable glass in circulation and out of our landfills.

How to Avoid Common Contamination Mistakes

The entire glass recycling process lives and dies by one crucial thing: purity. Think of it like a baker’s sourdough starter – just one wrong ingredient can ruin the whole batch. In the world of glass recycling, we call this contamination, and it’s the single biggest hurdle the industry faces.

When the wrong stuff gets tossed in with recyclable glass, it can spoil tonnes of valuable cullet. This doesn't just waste all the good material; it adds huge costs and burns more energy, completely undermining the point of recycling in the first place.

Getting your head around what causes contamination is the first step. The care you take at home or in your business makes a massive difference, ensuring all that effort to separate your bottles and jars really counts.

What Not to Put in Your Glass Recycling Bin

It might all look like glass, but not all glass is created equal. Different types are made with unique chemical recipes and melt at completely different temperatures. Mixing them is a recipe for disaster.

Here’s a clear list of the usual suspects that should never find their way into your glass recycling bin:

- Pyrex or Oven-Proof Cookware: This stuff is chemically hardened to handle extreme heat in your oven, which means it won’t melt properly in a standard glass furnace.

- Drinking Glasses and Vases: They might seem harmless, but drinking glasses and decorative vases often contain chemicals or have a different structure that weakens the final recycled product.

- Window Panes and Mirrors: These are manufactured completely differently from container glass. The chemicals used for tinting, strengthening, or creating that reflective surface are serious contaminants.

- Light Bulbs: From old-school incandescent bulbs to modern LEDs, these all contain metal filaments and other materials that are impossible to separate out. They will ruin a batch of cullet instantly.

- Ceramics, China, and Pottery: Things like mugs, plates, or terracotta pots simply do not melt in a glass furnace. Even tiny fragments can cause weak spots and defects in new glass bottles.

Putting just one of these items into the recycling can have a domino effect. A single ceramic mug breaking apart can contaminate tonnes of otherwise perfect cullet, potentially leading to the entire load being rejected and sent to landfill.

Keeping these items out is one of the most powerful things you can do to support proper glass recycling. For more guidance, check out our detailed tips for recycling which cover a whole range of materials.

Your Simple Preparation Checklist

Getting your bottles and jars ready is just as important as keeping the wrong stuff out. A few simple steps ensure the material is in the best possible shape for processing, boosting efficiency and the quality of the new glass.

Just follow this quick checklist to get it right every time:

- Empty and Rinse: Make sure containers are totally empty. A quick swill with water is all you need to get rid of residue that can attract pests and cause problems down the line.

- Remove Corks and Plastic Caps: While many plants can handle metal lids, things like corks, plastic screw-tops, and foil wrappings should always be taken off and binned separately.

- Check Local Rules on Lids: This is a big one, as the advice can change depending on where you live. Some councils want metal lids left on the jars, while others ask for them to be removed. Always check your local authority’s website.

- No Need to Remove Labels: Don't waste your time trying to peel off paper or plastic labels. The furnace is so hot that they simply burn away during the remelting process.

By following these simple guidelines, you become a key player in the circular economy. Every clean bottle you recycle properly contributes directly to a system that saves energy, resources, and our environment. It’s amazing how much impact these small efforts can have when we all do them together.

Managing Large Volumes of Glass Waste

While your household recycling bin and local bottle banks are great for day-to-day use, they just aren't built to handle the sheer amount of glass that businesses or large projects can produce. When you’re dealing with hundreds, or even thousands, of bottles instead of just a few, you need a far more robust plan.

Think about it: a pub clearing out after a packed weekend, a building firm finishing up a big renovation, or a caterer after a massive event. The mountain of glass they generate needs professional management. Trying to stuff it all into domestic bins isn't just a logistical nightmare; it's a safety hazard and can land you in hot water with waste disposal regulations.

That’s where professional waste management comes in. We provide the right containers, reliable collections, and the know-how to handle huge quantities of glass safely and properly, making sure it gets exactly where it needs to go for the recycling of glass bottles.

Solutions For Construction and Renovation Projects

Building sites and home renovations are massive sources of glass waste, and it’s not just bottles and jars. We’re talking about old window panes, glass fixtures, and offcuts. Trying to manage this mix of materials requires a structured approach to keep everything separate.

Hiring a skip is hands-down the easiest and most effective way to handle these temporary, high-volume jobs. Skips are available in a whole range of sizes, so you can pick one that’s a perfect fit for your project, whether it's a small kitchen refit or a full-scale building clearance.

By using a dedicated skip for glass and other recyclables, contractors ensure that valuable materials are kept separate from general rubbish. It's not just about better recycling; it shows a real commitment to responsible site management and doing things the right way for the environment.

This simple, organised step stops perfectly good glass from being buried in a landfill and makes the whole project more sustainable. It also makes the final site cleanup much easier, improves safety by containing broken glass, and ensures you’re ticking all the boxes for your legal duty of care.

Regular Collections For Hospitality and Businesses

For pubs, bars, restaurants, and hotels, a constant stream of empty glass bottles is just part of the daily grind. This kind of consistent output needs a permanent, reliable waste solution – not just a one-off collection.

Commercial wheelie bins, specifically for glass, are the industry standard for a reason. They’re tough, easy to wheel around, and come in various sizes to match your business’s needs. A good waste management partner will work with you to set up a collection schedule that stops bins from overflowing and keeps your premises looking clean and professional.

Here are the key benefits of a scheduled commercial service:

- Consistency: Your collections happen like clockwork, so you never have to stress about running out of space.

- Safety: Keeping glass properly contained drastically reduces the risk of injury from breakages for your staff and customers.

- Compliance: The service guarantees you meet all your legal duties for commercial waste, including providing the correct paperwork. To get your head around this, you can learn more about what a waste transfer note is and why it’s so vital for your business.

Choosing The Right Waste Management Partner

Picking a partner to handle your bulk glass waste isn’t just about finding the cheapest quote. A truly reliable provider offers a complete service that puts safety, compliance, and environmental responsibility first, taking the whole problem off your hands.

Look for a company that offers a proper range of containers, from different skip sizes for project work to various commercial bins for your ongoing needs. Flexibility is crucial, as is a clear pricing structure and a solid reputation for great customer service. At The Waste Group, we create tailored solutions to make sure your glass waste is handled efficiently and sustainably, turning a potential headache into a smooth, seamless part of your operation.

Your Glass Recycling Questions Answered

Even after understanding the journey a glass bottle takes, it’s normal to have a few questions. The world of waste management has its own quirks, and getting the small details right can make a massive difference. Here are some straightforward answers to the questions we hear most often.

Think of this as your quick-reference guide to recycling glass with total confidence. We’ll tackle everything from why colour-sorting matters to what really happens with those pesky bottle tops, clearing up any confusion along the way.

Why Is Separating Glass By Colour So Important?

Separating glass bottles by colour—clear, green, and brown—is absolutely vital for creating high-quality new products. When glass is melted down, it keeps its original colour, meaning a batch of new clear bottles can only be made from clear cullet.

It’s just like doing laundry; you wouldn’t throw a bright red sock in with your whites and expect them to come out pristine.

When different colours get mixed, the result is a low-grade, often dark-coloured glass with very limited uses. While some cutting-edge facilities use optical scanners to separate colours automatically, sorting it at the source is much more efficient.

By using the colour-separated bottle banks, you’re doing a crucial quality control step yourself. This simple act keeps the recycling stream pure, making the whole process more effective and helping manufacturers create top-quality new containers.

This initial sorting step seriously boosts the value of the collected glass and is a cornerstone of a genuine closed-loop system.

Do I Need to Remove Lids and Labels from Bottles?

This is probably the most common question we get, and the answer has a couple of parts. Generally speaking, you don’t need to spend time scraping off paper or plastic labels. During the remelting process, the furnaces reach incredibly high temperatures that easily burn away any leftover label residue.

Lids, however, are a different story. Here’s a quick breakdown:

- Metal Lids: In most cases, you can leave metal lids (like those on jam jars) on. At the recycling plant, powerful industrial magnets are set up to pull them out of the crushed glass during processing. Still, it's always a good idea to check your local council's specific guidance.

- Plastic Caps and Corks: These are definite no-nos. Plastic screw-tops and corks from wine bottles should always be removed and put in your general waste bin, as they are contaminants that can ruin the purity of the glass cullet.

The most important things you can do are to make sure the container is empty and give it a quick rinse to get rid of any food or drink residue.

What Happens to Glass That Cannot Be Recycled?

Not all glass is created equal, which is why items like drinking glasses, window panes, and oven-proof dishes don’t belong in your bottle bank. These products have different chemical compositions and melt at different temperatures than container glass. If they get mixed in, they can weaken new bottles and even cause entire batches to be rejected.

But that doesn’t mean they’re destined for landfill. This non-recyclable glass is often put to good use in other ways. Instead of being melted, it’s crushed and repurposed as an aggregate for construction projects.

This crushed glass is often used for:

- Road Building: As a component in asphalt to create durable road surfaces.

- Decorative Materials: Used in landscaping, countertops, or tiles.

- Filtration Systems: Employed as a medium for filtering water.

This is sometimes called 'downcycling' because the material isn't made back into a new version of itself. However, it’s a brilliant way to ensure that even non-recyclable glass has a valuable second life, keeping it out of the ground.

Is It Better to Reuse Glass Bottles or Recycle Them?

From a purely environmental perspective, reusing a glass bottle is always the best option. When you reuse a container, you completely skip the energy-intensive process of collection, transport, crushing, and remelting. Every single time a bottle is refilled, it represents a huge saving in energy and resources.

Of course, for most households and businesses today, a large-scale, systematic reuse programme isn't practical. This is where recycling steps in as the next best thing, and it's leagues better than sending glass to a landfill.

The ideal environmental hierarchy is simple:

- Reduce: The best thing you can do is reduce the amount of single-use packaging you buy in the first place.

- Reuse: If you can, find ways to reuse glass containers at home for storage or other creative purposes.

- Recycle: When reuse isn’t an option, recycling is the essential final step to close the loop and keep the material in circulation.

Recycling saves an enormous amount of energy and raw materials compared to making new glass from scratch, making it a true cornerstone of sustainable waste management.

Managing glass waste effectively, whether from a small home renovation or a large commercial site, is key to a greener future. For reliable, compliant, and efficient waste solutions in Dorset, The Waste Group offers everything from skip hire to scheduled commercial collections. Explore our services and get a quote online today.