Mastering Waste Management for Construction Projects

Mastering Waste Management for Construction Projects

Proper waste management isn't just a box to tick; it's the bedrock of a profitable, compliant, and well-regarded construction project. It’s a whole process of planning, sorting, and getting rid of materials in a way that slashes costs, minimises your environmental footprint, and can even turn old materials into new resources.

Why Smart Waste Management Is Non-Negotiable

If you're still seeing waste management as just another cost on the spreadsheet, you're missing a trick. Think of it more as a strategic tool for making your projects run smoother, keeping a tight grip on expenses, and boosting your company's name. A solid approach goes way beyond just ordering a skip when things pile up; it’s a system you put in place long before the first boot steps on site.

And let's be clear, this isn't just about being green—it hits your bottom line directly. Every single tonne of waste chucked into a landfill comes with a hefty price tag. By simply sorting materials like wood, metal, and plasterboard right there on site, you can cut those costs down dramatically. In fact, clean, segregated recyclables often have a much lower disposal fee, and some can even be sold on, turning your rubbish into revenue.

The Scale of the Challenge

The amount of waste our industry produces is mind-boggling. The UK construction industry is the single largest generator of waste in the country, churning out an incredible 62% of all UK waste. That's about 100 million tonnes every year.

Now, we've made brilliant strides, with over 90% of this material now being recovered. But there's still a stubborn problem: around 5 million tonnes still ends up buried in landfill. You can dive deeper into the numbers with these UK construction waste statistics at Waste Direct.

These figures really drive home why you need a plan. Without one, sites quickly become messy, dangerous, and far more expensive to run than they need to be.

More Than Just Financial Gains

Beyond saving cash, a well-thought-out waste management plan gives you a serious competitive edge in a few key ways.

- A Better Company Image: Let's face it, clients and investors care more and more about sustainability. Showing you’re serious about responsible waste handling makes your brand look good and can be the very thing that helps you win a competitive tender.

- A Safer, More Organised Site: A tidy site is a safe site. It’s that simple. Having designated areas for different types of waste gets rid of trip hazards, cuts down on clutter, and just creates a much more professional environment for everyone involved.

- Staying on the Right Side of the Law: Following the 'Duty of Care' regulations isn't a choice—it's a legal requirement. A proper, documented waste management process gives you a clear audit trail, protecting your business from eye-watering fines and legal trouble.

A well-executed waste plan is a hallmark of a professional contractor. It signals to clients, regulators, and your own team that you are in complete control of the project, from materials procurement to final disposal.

Crafting Your Site Waste Management Plan

Trying to run a construction site without a waste plan is a bit like building without a blueprint. You might get there in the end, but it’ll be chaotic, inefficient, and almost certainly more expensive than it needed to be.

A Site Waste Management Plan (SWMP) is your command centre for waste. Think of it less as a document and more as a live strategy for keeping costs down and meeting your legal duties.

While a formal SWMP is no longer a legal requirement in the UK, it’s become an industry best practice for a good reason. It helps you get organised. Plus, you’re still bound by your responsibilities under Section 34 of the Environmental Protection Act 1990, which means you have to ensure all waste is handled correctly from start to finish. An SWMP is simply the best way to prove you’re doing just that.

You can explore the guide to construction waste from Waste Managed to get a better handle on this voluntary but vital tool.

A good SWMP shouldn’t be a hundred-page novel that gathers dust in the site office. It needs to be a practical tool that everyone on the project can actually use.

Starting with Accurate Estimates

First things first: you need to forecast the waste your project is going to create. You can't manage what you don't measure. The easiest way is to break it down by the phase of the project—demolition, groundwork, the main build, and finishing touches—as each stage throws out very different materials.

Get specific. Instead of just "rubble," think in terms of:

- Inert Waste: Concrete, bricks, tiles, and soil.

- Non-Inert Waste: Timber offcuts, plasterboard, insulation, and packaging.

- Hazardous Waste: Things like asbestos, treated wood, or containers with chemical residues.

This level of detail helps you plan for the right number and type of skips. It prevents both costly over-ordering and the last-minute panic to get another skip on-site, which always seems to happen at the worst possible time.

Setting Clear Goals and Responsibilities

Once you know what you’re dealing with, you can set some real targets. Keep them simple and measurable. For instance, you could aim to recycle 95% of all inert waste or reduce plasterboard offcuts by 10% through smarter ordering.

This is the crucial part: someone needs to own it. Assign a "Waste Champion"—usually the site manager—who is responsible for the plan. They need to oversee everything, train the team, and make sure everyone knows their role. A plan without an owner is just a piece of paper.

Your SWMP must create an unbroken chain of custody for every bit of waste leaving your site. That means documenting who collected it, when they collected it, and where it’s going. This paperwork is your proof of compliance.

This is all part of your 'Duty of Care' obligations. The government provides clear guidelines on what’s expected.

The screenshot below, taken from the official Code of Practice, shows the key steps for staying compliant.

The main takeaway here is the importance of checking that your waste carrier is registered and that you get a complete Waste Transfer Note for every single load. This isn't just admin for the sake of it; it's your legal defence if your waste gets fly-tipped or mishandled after it leaves your control. It’s all about building a solid, auditable trail from your site to the final disposal facility.

Implementing On-Site Waste Segregation That Works

A detailed waste plan looks great on paper, but it’s the execution on the ground that really counts. Sorting your waste at the source—what we call segregation—is without a doubt the most effective way to boost recycling rates and slash your disposal costs. This is where the theory of waste management for construction gets its boots muddy.

The aim is simple: move from a chaotic pile of mixed rubbish to a genuinely organised system. And the secret to success? Making it dead easy for everyone on site to do the right thing.

Setting Up a Functional Waste Compound

First things first, you need a dedicated, well-organised waste compound. This can't be an afterthought or a forgotten corner of the site. It needs to be a clearly marked, easily accessible area where all your skips and bins live.

Think about the logistics. Can a skip lorry get in and out without causing a traffic jam for the rest of the site? Is the ground level and stable? A poorly placed compound quickly becomes a bottleneck and a safety hazard, which is the fastest way to get people to stop using it properly.

From there, you need to choose the right number and type of containers. This decision goes right back to your initial waste estimates. If you’re expecting a mountain of rubble, a dedicated inert waste skip is a non-negotiable. Likewise, separate skips for timber, metal, and plasterboard often pay for themselves by helping you swerve those hefty mixed-waste charges.

Choosing the Right Skips for the Job

Figuring out your skip setup is always a bit of a balancing act. Too many skips can eat up valuable space, but having too few leads to cross-contamination. And once that happens, your valuable recyclables instantly become an expensive landfill problem.

To help you get started, this table outlines some of the most common waste streams you'll encounter on a construction site and the best ways to handle them.

Common Construction Waste Streams and Segregation Methods

| Waste Material | Typical Sources | Recommended Segregation | Recycling/Disposal Path |

|---|---|---|---|

| Inert Waste | Bricks, concrete, rubble, soil, hardcore | Dedicated inert waste skip | Crushed for aggregate (MOT Type 1) |

| Wood/Timber | Pallets, offcuts, shuttering, untreated wood | Separate wood skip or designated pile | Chipped for biomass or board manufacturing |

| Scrap Metal | Rebar, pipes, steel beams, copper wiring | Secure metal skip or container | Sent to a scrap metal recycler (high value) |

| Plasterboard | Offcuts, demolition waste (gypsum-based) | Must be kept separate; dedicated skip/bags | Specialist recycling to separate gypsum/paper |

| Plastics | Pipes, packaging film, window frames | Separate containers for different plastic types | Varies by polymer type; sent for reprocessing |

| General Waste | Mixed packaging, insulation, contaminated items | General waste skip (the last resort) | Sent to a MRF for sorting or energy recovery |

Using a clear system like this on-site not only simplifies the process for your team but also ensures you're maximising the value of your waste while minimising your environmental impact.

Before you get the skips delivered, it’s vital to be crystal clear on what can and can’t go into each one. For a full rundown, you can learn more about what can go in a skip in our detailed guide. It covers everything from accepted materials to absolute no-gos like hazardous waste. Getting this right is fundamental.

A common mistake is ordering one massive "mixed waste" skip to try and keep things simple. It might seem easier at first, but it nearly always ends up costing more because the whole lot has to be sorted at a Materials Recovery Facility (MRF), where contamination rates are much higher.

The Power of Clear Communication

Even the most perfectly organised waste compound is doomed to fail without clear and constant communication. Your team needs to know what goes where, and they need to be reminded often.

Your most powerful tool here is simple, effective signage. Forget about an A4 piece of paper in a plastic sleeve—it’ll be illegible after the first downpour. Invest in large, weatherproof signs with clear text and pictures showing exactly what belongs in each skip. Put them right on or above the container so there’s no room for confusion.

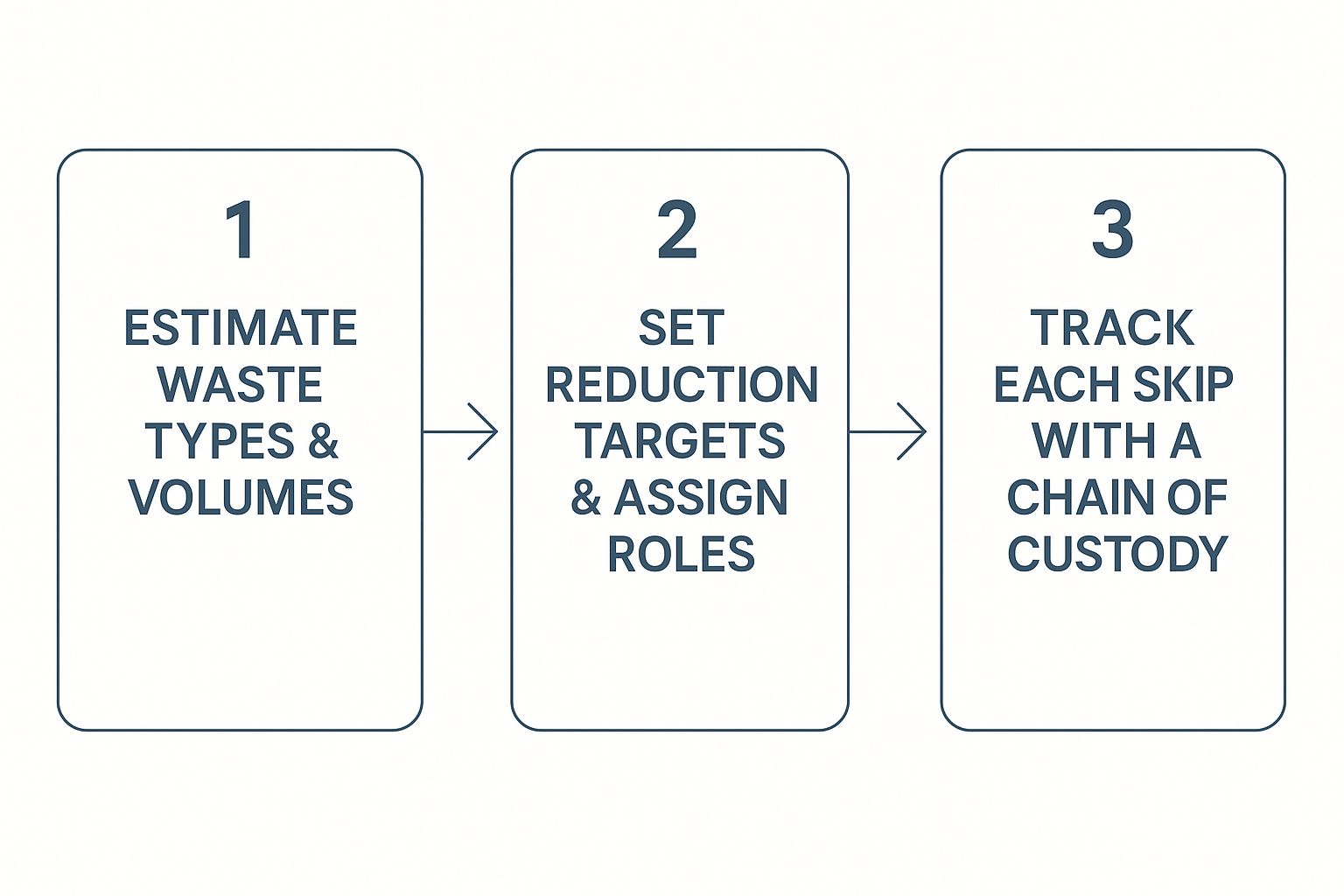

This infographic gives a great overview of the process, showing how everything connects.

As you can see, tracking each skip is the final piece of the puzzle, which just goes to show how important clear segregation is right up to the moment of collection.

But don’t just rely on signs. Make waste segregation a regular topic in your toolbox talks and site briefings. Never assume everyone knows the plan. On their first day, walk new starters through the waste compound. When you make proper waste management a visible priority, your team is far more likely to get on board and help you hit your targets.

Meeting Your Legal Duty of Care for Waste Disposal

Once your skips are full and ready for collection, a crucial set of legal responsibilities kicks in. Here in the UK, it’s known as your Duty of Care. This isn't just a bit of friendly advice; it's a legal obligation for every contractor out there, making sure waste is handled safely and properly from the moment you create it to its final stop.

Getting this wrong can lead to unlimited fines, so it’s something you really need to get your head around. It’s all about creating a clear, auditable trail for every single load of waste that leaves your project.

Choosing a Licensed Waste Carrier

First things first, you have to be absolutely sure that anyone taking your waste away is legally allowed to do so. It’s actually an offence to hand your waste over to an unlicensed carrier. Any reputable company will have their waste carrier licence number ready to share, but you should always double-check it for yourself.

It only takes a couple of minutes. Just pop over to the Environment Agency's public register online and enter the company's name or licence number. You'll see straight away if they're registered and, crucially, if they're authorised to handle the specific types of waste your site produces.

- Actionable Tip: Make this check a non-negotiable part of your subcontractor vetting process. Keep a digital or paper copy of their current licence in your project files. It’s a simple step, but it’s your first and best line of defence.

The Importance of Waste Transfer Notes

The Waste Transfer Note (WTN) is the absolute cornerstone of your Duty of Care. Think of it as the passport for your waste. This legal document has to be filled out for every single load leaving your site, acting as both a receipt and a permanent record. It proves you've done your bit to ensure the waste is being handled by the right people and is heading to a legitimate facility.

To be compliant, the WTN needs to have some specific details:

- A Clear Description: You can't just write "builders' rubble." You need to describe the waste accurately using the correct List of Wastes (LoW) code, also called a European Waste Catalogue (EWC) code. For instance, "mixed construction and demolition wastes" has the code 17 09 04.

- Containment Details: A quick note on how it's being stored, like "in an 8-yard skip."

- Quantity and Weight: A realistic estimate of how much waste there is.

- Your Details: Your company's name and address as the producer of the waste.

- Carrier's Details: The name, address, and licence number of the firm collecting it.

- Destination Address: The full address of the authorised facility where the waste is going.

Both you and the carrier have to sign and date the note. Your copy needs to be kept safe for at least two years, as it's your proof of compliance if an inspector ever pays a visit.

A classic mistake is signing a vague or half-finished Waste Transfer Note. If key details are missing or wrong, that document is worthless. If that waste ends up fly-tipped, the responsibility could trace right back to you. Always give it a proper check before you sign.

Handling Hazardous Construction Waste

Some materials you’ll find on-site are a different beast altogether. They fall under a much stricter set of rules because they’re hazardous, and a standard WTN just won’t cut it. For these, you must use a Hazardous Waste Consignment Note.

We're talking about materials like:

- Asbestos sheets or fragments

- Treated timbers (think old railway sleepers or telegraph poles)

- Certain paints, solvents, and adhesives

- Oily rags and contaminated soil

These items can't ever be mixed in with your general waste. They must be collected by a carrier with a specific licence to handle hazardous materials. For a deeper dive into the specific legal requirements, you can learn more by reading our article on hazardous waste disposal regulations.

When you're dealing with different waste streams, especially the hazardous kind, proper storage is key. If your site generates chemical waste, for instance, getting advice on selecting appropriate chemical storage solutions can be a huge help in staying compliant.

Ultimately, getting waste disposal right is a shared responsibility. UK law identifies both employers and contractors as waste producers, so the duty of care falls on everyone involved, not just the main contractor. Mastering these legal duties isn't just good practice—it's non-negotiable for running a professional and compliant operation.

Boosting Recycling and Finding Value in Your Waste

The best waste management plans don’t just clear rubbish off a site; they’re designed to turn discarded materials into genuine assets. This isn't just about ticking an environmental box—it’s about smart economics that can seriously reduce your costs and sometimes even bring in a bit of revenue.

While the national statistics on recycling look good on paper, what happens on individual projects can be a completely different story. The real difference often boils down to one thing: knowing what happens to your waste after it leaves your gate. Make better segregation choices on-site, and you can directly influence just how much of your material gets a second life.

The Journey of Recovered Materials

Ever wondered what actually happens to that skip full of broken concrete or those timber offcuts? When you know the final destination, it’s much easier to see the point of separating everything properly. It gives your team's efforts a tangible purpose.

So, where is it all going?

- Concrete and Rubble: This is a recycler's dream. Heavy, inert waste like this usually goes to a processing facility where it’s crushed and screened. The end product is recycled aggregate, like MOT Type 1, which goes straight back into new construction projects for sub-bases and road building.

- Wood and Timber: As long as it’s not contaminated, wood is a fantastic resource. It’s often shredded for animal bedding or, more commonly, chipped for biomass fuel to generate renewable energy.

- Scrap Metal: Separated metals like steel, aluminium, and copper always hold good value. They’re taken to scrap yards, melted down, and reformed into brand-new metal products. It’s a perfect, highly efficient recycling loop.

The UK has made huge strides here. England’s recovery rates for non-hazardous construction and demolition waste have been consistently over 90% for more than a decade, hitting a brilliant 94.3% in 2022. Out of 63.0 million tonnes of waste generated, a massive 59.4 million tonnes were recovered. That’s a testament to good industry practice and the clear economic sense it makes. You can explore the full UK waste data on the government's website.

Turning Waste into an On-Site Asset

Looking beyond sending materials off-site, some of the biggest wins come from reusing waste without it ever leaving your project. This move completely wipes out haulage and disposal fees, turning a liability into a free resource right where you need it.

Think about processing your excavated soil and stone directly on-site. Mobile crushing and screening equipment can turn subsoil and rubble into perfectly good fill material or landscaping aggregate. This means you skip the cost of hauling it away and avoid paying to bring in virgin materials to do the same job. It’s a classic win-win.

By thinking of waste not as rubbish but as "material in the wrong place," you shift your entire perspective. This mindset is the foundation of a circular economy, where resources are kept in use for as long as possible.

This thinking is at the heart of modern, sustainable construction. To get a better grasp of how these principles come to life, take a look at our guide on how the circular economy and waste management work together. It’s all about designing a system that gets rid of waste from the very start.

Choosing the Right Partners for Recovery

Your choice of waste management provider is absolutely crucial. A good one won't just be a "skip and collect" service; they’ll work with you as a strategic partner to help you get the most out of your waste streams.

Don’t be afraid to ask potential suppliers some direct questions. Where do they take their materials? What are their verified recycling and recovery rates? A transparent partner will happily provide detailed reports showing exactly where your waste is going. That data is gold for your sustainability reporting and helps you keep getting better. When you understand their operations, you can be confident that your efforts on-site are leading to the best possible results, both for the planet and your project’s bottom line.

Using Technology to Streamline Waste Management

Let's be honest, manual paperwork and clunky spreadsheets have no place in modern construction waste management. They’re slow, prone to error, and a massive time drain. Thankfully, digital tools are stepping in, offering a far smarter way to handle everything from compliance to data tracking.

This isn't just about going paperless for the sake of it; it’s about making your entire operation more efficient. Specialist software can completely digitise your Waste Transfer Notes, creating an instant and secure record of every single load that leaves your site. This simple switch saves hours of admin and, crucially, means you never have to worry about losing vital compliance documents again.

Digital Platforms and On-Demand Services

Beyond just digital paperwork, a new wave of platforms is completely changing how we book waste services. Imagine tapping into a network of local, pre-vetted waste carriers in minutes. These systems let you request on-demand collections and get competitive quotes back, ensuring fair pricing without having to spend half your morning on the phone.

This brings a level of flexibility to site logistics that just wasn't possible before. A sudden need for an extra skip or an emergency grab lorry collection can be sorted through a simple app, keeping your project on track and avoiding costly delays.

Adopting these tools gives you a clear, data-backed view of your project's environmental footprint. It moves waste management from a reactive chore to a proactive, data-driven part of your project strategy—something that’s invaluable for client reporting.

Data Analytics for Better Decisions

The real game-changer here is the data. When you track waste generation in real time, you start to see patterns you’d otherwise miss, allowing you to pinpoint and fix inefficiencies on the ground.

- Pinpoint Waste Hotspots: See exactly which phase of the project or which specific trade is creating the most waste.

- Monitor Segregation Success: Track how much contamination is ending up in your segregated skips to see if your team's training is actually working.

- Generate Sustainability Reports: Effortlessly pull together polished, accurate reports for clients and stakeholders, showcasing your commitment to responsible site management.

This data-led approach helps you make smarter decisions on everything from material ordering to managing your subcontractors.

It’s also worth looking at other site technologies. For example, advanced site monitoring can have a huge knock-on effect on efficiency. To see how things like drones are being used, check out this guide on drone use in construction. When you combine these tools, you get a complete picture of your site’s operations, helping you manage all your resources—waste included—more effectively than ever before.

Questions We Hear All the Time on Site

Even the best-laid plans can hit a snag on a bustling construction site. When it comes to waste, you need clear, quick answers to keep things moving smoothly and, most importantly, legally. Here are some of the questions that come up time and time again.

What Are the Biggest Muck-ups with Waste Segregation?

The most common—and most expensive—mistake we see is cross-contamination. Simple as that. Someone chucks a bit of plasterboard into the inert waste skip, or general rubbish gets buried under a load of clean timber, and suddenly the entire container is contaminated. It instantly downgrades the whole lot.

This usually boils down to a couple of things: either the skips aren't clearly signed, or the team hasn't been properly briefed.

Another classic error is picking the wrong skip strategy. It might feel easier to just order one massive mixed waste skip, but it almost always costs you more in the long run. You’re not just paying a premium for someone else to sort it; you’re also running a much higher risk of contamination, which means less of your waste actually gets recycled.

What Do I Do If I Find Something Hazardous?

Finding unexpected hazardous materials—think old asbestos insulating board or forgotten chemical drums—is a scenario that can grind a project to a halt. If this happens, your response needs to be immediate and by the book.

- Down tools. Stop all work in that area straight away.

- Cordon it off. Secure the area so no one can wander in.

- Don't touch it. This is critical. Don't try to move it or handle it yourself.

- Call in the experts. You need to contact a specialist contractor licensed to identify and remove hazardous waste.

This isn't just about best practice; it's a legal requirement that protects your team and the public. Whatever you do, don't be tempted to just hide it in a general waste skip. The consequences are severe.

Finding hazardous waste isn't a failure, but failing to deal with it properly is. A fast, compliant response protects your project, your reputation, and most importantly, your people. It’s a non-negotiable part of your Duty of Care.

Can I Reuse Materials from the Demolition in the New Build?

Absolutely. In fact, it’s a brilliant move for cutting costs and boosting your project’s green credentials. But, and this is a big but, it's not as simple as pulling old bricks out of one wall and sticking them in another.

Any material you reuse has to be fit for purpose and meet current building regulations.

For things like reclaimed aggregates (think crushed concrete), you've got to follow the WRAP Quality Protocol. This process ensures the material is properly tested and processed, at which point it officially stops being "waste" and becomes a certified product. Using materials that haven't been through this process is not only potentially illegal but could seriously compromise the structural integrity of your build.

At The Waste Group, we provide the expert advice and reliable services you need to manage every aspect of your construction waste. From skip hire to specialist disposal, we ensure your project stays compliant and efficient. Find out more at https://www.thewastegroup.co.uk.