Construction Waste Management Tips for Better Waste Management in Construction

Construction Waste Management Tips for Better Waste Management in Construction

When we talk about waste management in construction, we're not just talking about getting rid of rubbish. It’s a proper strategy for planning and dealing with all the stuff left over from building, demolition, and renovation jobs. It's about shifting your mindset from just chucking things away to actively reducing, reusing, and recycling materials. Get this right, and you'll minimise both environmental damage and the hit to your wallet.

Confronting the Scale of Construction Waste

Staring at a mountain of site waste can feel a bit much, but getting your head around the true scale of the problem is the first step to sorting it out. The figures are genuinely staggering. This isn't a minor headache; it's the single biggest contributor to the UK's entire waste problem.

Believe it or not, the construction industry is the largest producer of waste in the UK, churning out around 62% of the total waste generated every single year. We’re talking about 100 million tonnes of construction waste annually, a process that also eats up about 400 million tonnes of natural resources. It’s a massive figure, and large-scale jobs involving earthmoving, sometimes needing specialized dredging equipment, add even more to this huge volume.

Why This Matters for Your Project

So, what does 100 million tonnes actually look like? Picture this: it’s enough rubbish to fill Wembley Stadium nearly 25 times over, every single year. This isn't just some abstract number; it represents a colossal loss of valuable materials and puts an incredible strain on our landfills.

For contractors and homeowners, this translates directly into higher disposal costs, the risk of fines if you don't comply with regulations, and a huge missed opportunity to run your project more efficiently. Good waste management isn’t just about ticking a box; it’s a core business priority that directly impacts your bottom line.

By starting to see waste as a resource instead of a liability, you can unlock serious cost savings, boost your company's reputation, and help build a more sustainable industry. The environmental impact of construction waste is huge, and taking control is the only way to tackle it.

Adopting the Waste Hierarchy

The "waste hierarchy" is the go-to framework for smart waste management. Think of it as a simple pyramid of priorities that guides you towards the best course of action.

- Reduce: The best thing you can do is stop creating waste in the first place. This all comes down to careful planning, ordering materials precisely, and embracing modern methods like prefabrication.

- Reuse: Before you even think about recycling something, ask yourself if it can be used again. This could be anything from salvaging bricks and timber to fixtures that can be used elsewhere on-site or on another project entirely.

- Recycle: For materials that can't be reused, recycling is the next best step. It means separating things like concrete, metal, wood, and plasterboard so they can be processed and turned into new products.

- Recover: This step is about getting some value back, usually by recovering energy from waste through processes like incineration.

- Dispose: Landfill is the absolute last resort. It's the least desirable option, both for the environment and for your budget.

Following this hierarchy helps you move from simply reacting to waste to proactively managing it. It’s a straightforward roadmap for turning what was once a major cost into a source of real efficiency and savings.

Getting to Grips with Your Legal Duties on Site

Let's be honest, the legal side of construction waste can feel like a maze of confusing rules and endless paperwork. But getting your head around your core responsibilities is the only way to dodge hefty fines and keep your project on track. This isn’t just about getting rid of rubbish; it’s about managing it properly from the moment it’s created to its final destination.

At the very heart of UK waste law is the 'Duty of Care'. This isn't just a friendly suggestion—it's a legal obligation for absolutely everyone who produces, carries, keeps, or disposes of controlled waste. Put simply, you are legally on the hook for your waste until it has been properly and legitimately disposed of.

That responsibility goes far beyond just ordering a skip. You have to make sure that everyone who handles your waste, from your own team on site to the company you hire to haul it away, is authorised and licensed to do so. If you don't, you could face massive penalties, even if you weren’t the one who fly-tipped the material.

Understanding Your Duty of Care

Think of your Duty of Care as a chain of custody for your waste. You're the first link, and it's your job to ensure every single link that follows is secure and compliant. This means taking real, practical steps on the ground to manage waste correctly from day one.

This involves storing waste securely so it can't escape, using the right containers, and making sure it doesn't cause harm to people or the environment. A massive part of this is being able to accurately describe the waste you're handing over.

The essence of your Duty of Care is this: ensure your waste is handled by an authorised professional and keep a complete paper trail to prove it. This is where a Waste Transfer Note comes in, documenting the moment that waste leaves your control and is passed to a licensed carrier.

This single document is your proof that you’ve done your bit. It needs to include specific details about the waste—what it is, how much there is, and how it's contained. Both you and the carrier have to sign it, and you must keep your copy for at least two years.

The Role of a Site Waste Management Plan

For bigger projects, a more structured approach is often needed. While it's no longer a strict legal requirement for all projects in England, a Site Waste Management Plan (SWMP) is still seen as the gold standard of best practice. In fact, many clients and local authorities will insist on one.

An SWMP is basically your project’s roadmap for waste. It’s a live document, drawn up before you even break ground, that details how you'll manage materials efficiently and dispose of everything legally. It forces you to think ahead about what kind of waste you'll be creating, and how much of it.

A solid SWMP usually includes:

- Waste Forecasts: A good estimate of the different types of waste you expect the job to generate.

- Waste Carriers: Details of the licensed companies you plan to use for disposal.

- Disposal Sites: The names and permit numbers of the facilities where your waste is heading.

- Action Plan: Clear, practical steps for reducing, reusing, and recycling materials throughout the build.

Staying Compliant and Avoiding Fines

At the end of the day, staying compliant is about being proactive, not reactive. It comes down to keeping meticulous records and always, always checking the credentials of your waste partners. Before you hire anyone, ask to see their waste carrier's licence and double-check it on the Environment Agency's public register.

Here’s a quick checklist to help you stay on the right side of the law:

- Segregate Your Waste: Keep different materials separate. This prevents contamination and makes recycling a whole lot easier.

- Use a Licensed Carrier: Always confirm your waste contractor is registered with the Environment Agency. No licence, no job.

- Complete a Waste Transfer Note: Make sure every single collection is documented with a properly filled-out and signed note.

- Keep Your Records: File away all your Waste Transfer Notes and keep them safe for a minimum of two years.

- Prevent Fly-Tipping: Secure your site and your waste containers to stop anyone from accessing them or dumping illegally.

By weaving these simple habits into your daily site routine, you can turn those legal duties from a headache into just another part of running a professional, responsible, and well-managed project.

Putting The Waste Hierarchy Into Practice

The waste hierarchy isn't just a textbook theory; it's a practical, money-saving framework for smarter waste management in construction. When you start focusing on preventing waste rather than just disposing of it, you can completely change how your site operates. This shift turns potential costs into genuine assets.

Let's break down how to apply these core principles—Reduce, Reuse, and Recycle—with real-world steps that make a difference on any job site.

Start By Reducing Waste At The Source

The cheapest and most effective way to manage waste is simple: don't create it in the first place. This is the top tier of the hierarchy, 'Reduce', and it’s all about sharp planning and precision. Every single piece of material you prevent from becoming waste is a direct saving on both your purchase and disposal costs.

A brilliant first step is getting your ordering spot on. Applying some solid small business inventory management tips helps you stop over-ordering materials. Instead of guesstimating, use your project plans to calculate the exact amount of plasterboard, timber, and concrete you need. It’s a simple discipline that prevents the costly mistake of having surplus stock left to chuck in a skip.

Here are a few other smart reduction tactics:

- Precision Ordering: Work with suppliers who can help with take-off services, or use software to dial in your material needs down to the last brick.

- Off-Site Construction: Using prefabricated components like timber frames or bathroom pods massively cuts down on-site cutting, mistakes, and the waste that comes with them.

- Just-in-Time Delivery: Why have materials sitting around for weeks? Schedule deliveries for when you actually need them. This minimises the risk of damage on a busy site and keeps things clear.

Give Materials A Second Life Through Reuse

Before you toss anything, always ask: can this be used again? The 'Reuse' principle is all about spotting the value in salvaged items, a practice that's great for your budget and the environment. It just needs a slight change in mindset—seeing old materials as resources, not rubbish.

On demolition and renovation jobs, this can be a goldmine. Carefully taking things apart instead of just smashing them can yield a fantastic inventory of reusable materials. For example, old timber joists can be de-nailed and used for non-structural work, while salvaged bricks can add real character to a new garden wall or feature.

Think of every salvaged item as a direct cost saving. A reclaimed door means one less new door to buy. A pallet of cleaned bricks saves you the cost of purchasing new ones and paying to dispose of the old.

Even simple things like reusing timber off-cuts for noggins or protective coverings make a site more efficient and less wasteful. Fixtures like sinks, radiators, and light fittings in decent condition can often be sold or donated, keeping them out of landfill and building a bit of goodwill at the same time.

Maximise Value Through Smart Recycling

When reduction and reuse aren't an option, 'Recycle' is your next best bet. Effective recycling boils down to one critical action: segregation. Mixing different types of waste contaminates perfectly good materials, often condemning the entire load to landfill. By keeping waste streams separate on-site, you make them far easier and cheaper to process.

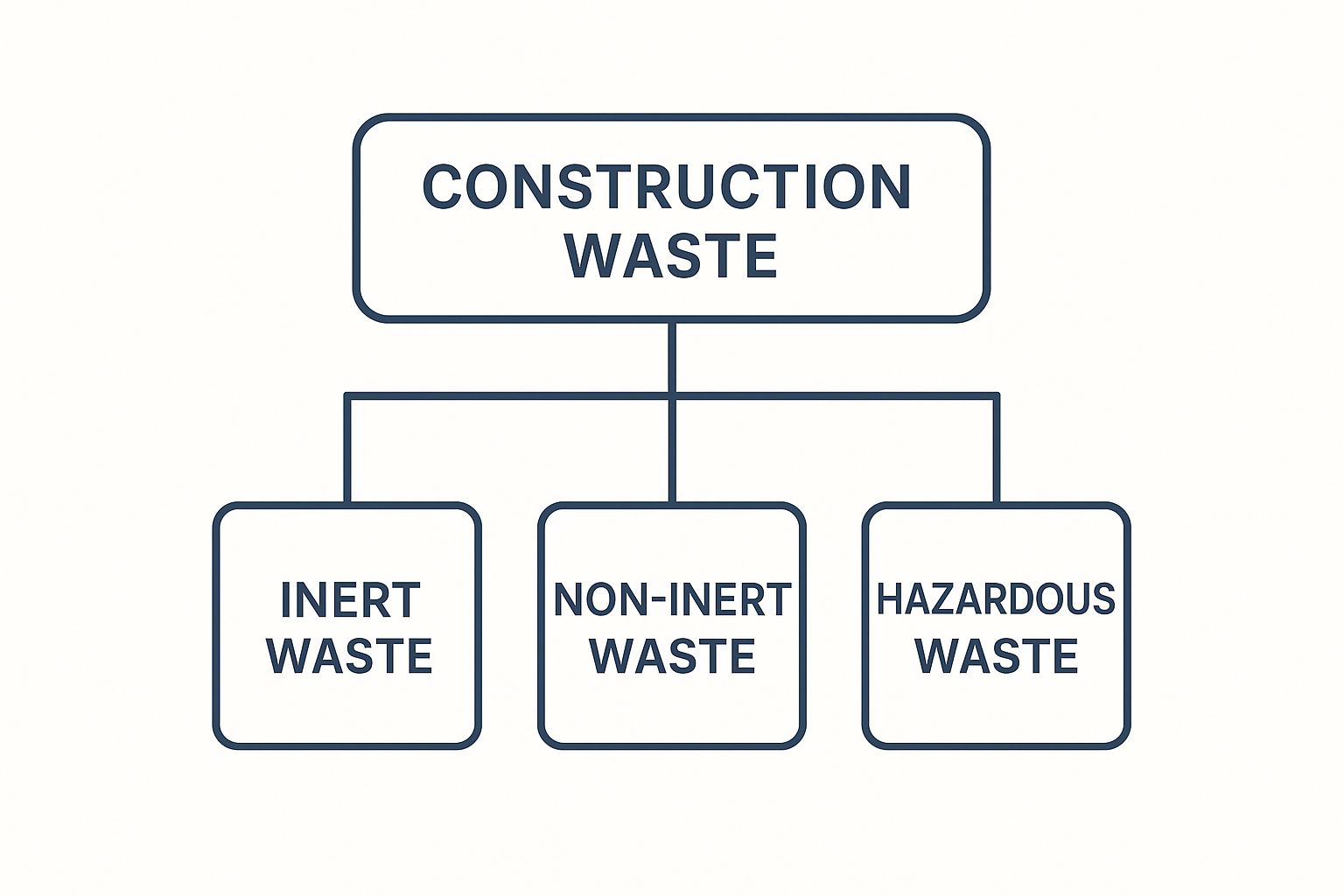

This chart shows the common waste categories you'll find on construction sites, which is the starting point for proper segregation.

Knowing these classifications helps you set up your site with designated skips or containers for each material. This prevents cross-contamination and sends your recycling rates through the roof.

The UK has actually made incredible progress here. In 2022, England generated 63.0 million tonnes of non-hazardous construction and demolition waste, and a staggering 94.3% of that was recovered. This impressive rate is largely down to recycling materials like crushed concrete into new aggregate, which keeps enormous volumes out of our landfill sites.

Here’s a quick guide to what you should be separating:

- Inert Waste: This is your soil, clay, concrete, bricks, and rubble. It’s heavy but highly recyclable, often getting crushed for use as hardcore or aggregate.

- Metals: Keep your ferrous metals (like steel) separate from non-ferrous ones (like copper and aluminium). They have a high scrap value and are very easy to recycle.

- Timber: Untreated wood can be chipped for landscaping or burned for biomass fuel. Remember, treated wood needs specialist disposal.

- Plasterboard: This one is non-negotiable. Plasterboard must be kept separate, as it releases harmful gases if it mixes with other waste in a landfill.

To tie this all together, here’s a table showing how you can apply these principles directly on your site.

Practical Application Of The Waste Hierarchy On Site

This table outlines actionable steps for each level of the waste hierarchy, providing clear, practical examples for contractors to follow.

| Hierarchy Level | Objective | On-Site Actions & Examples |

|---|---|---|

| Reduce | Minimise waste generation at the source | • Calculate exact material needs to avoid over-ordering. • Use prefabricated components to reduce off-cuts. • Schedule just-in-time deliveries to prevent damage. |

| Reuse | Find a second life for materials on-site | • Salvage bricks, tiles, and timber during demolition. • Use off-cuts for smaller tasks (e.g., noggins). • Clean and sell or donate old fixtures and fittings. |

| Recycle | Segregate materials for reprocessing | • Use separate skips for inert waste, metal, wood, and plasterboard. • Clearly label bins to avoid cross-contamination. • Crush concrete on-site for new aggregate. |

| Recover | Extract energy from non-recyclable waste | • Send non-recyclable, untreated wood to a biomass facility. • This is usually handled by your waste management partner. |

| Dispose | Send the absolute minimum to landfill | • Ensure hazardous materials (like treated wood, asbestos) are handled by specialists. • This should be the last resort for everything else. |

By truly embracing this hierarchy, you stop being a passive "disposer" of waste and become an active manager of resources. It's a move that's better for your project's environmental footprint and, crucially, for its bottom line.

Choosing the Right Waste Disposal Solution

So, you've done your best to reduce, reuse, and recycle, but there's always going to be some waste left over. Now comes the crucial bit: getting it off your site. Picking the right disposal method isn't just about clearing rubbish; it’s a big decision that affects your budget, your schedule, and whether you're staying on the right side of the law.

For most jobs, big or small, skip hire is the bread and butter of construction waste management. It’s simple, reliable, and keeps everything contained neatly in one place. The only real catch is picking the right size – get it wrong, and you're either paying for fresh air or having to order a second skip halfway through the job.

Finding the Perfect Skip Size

Skips are measured in cubic yards, and getting the size right from the get-go will save you a world of logistical headaches later.

-

Mini Skips (2-4 yards): These are your best friend for those tiny jobs. Think a weekend garden clearance or ripping out a small en-suite. They’re compact enough to tuck onto most driveways, which often means you can dodge the hassle of getting a permit for placing it on a public road.

-

Midi Skips (6-8 yards): This is the sweet spot for most domestic projects and smaller building works. The 8-yard skip, known by pretty much everyone as a "builder's skip," is the go-to for kitchen refits, extension jobs, and serious garden makeovers. It's the most popular size for a reason.

-

Large Skips (10-12 yards): Got lots of bulky but light stuff? These are for you. They’re ideal for shop fit-outs or clearing out a large house filled with old furniture. Just remember, they’re not built for heavy waste like soil or rubble – the lorry simply wouldn't be able to lift it.

-

Roll-On/Roll-Off (Ro-Ro) Containers (20-40 yards): These are the titans of the waste world. You’ll only see these on major commercial construction and demolition sites. They handle staggering amounts of waste, making them the only sensible choice for huge projects.

Think of choosing a skip like picking the right tool for the job. You wouldn't use a sledgehammer to hang a picture frame, and you wouldn't order a 40-yard Ro-Ro for a simple garden tidy-up. Matching the container to the task is key to efficiency.

Comparing Construction Waste Disposal Options

While hiring a skip is often the first thought, it's not the only game in town. Depending on what you're dealing with, another service might actually be a much better fit. It pays to know the pros and cons of each to find that perfect balance of cost, convenience, and capacity.

A 'man and van' service, for instance, offers a totally different kind of help. Here, a team shows up and does all the heavy lifting for you. It's perfect if you're short on time or just don't fancy lugging everything yourself, especially for quick, one-off clearances.

Then you have grab lorries. These are brilliant for shifting massive amounts of inert waste like soil and hardcore. Their hydraulic arm can reach over fences and walls to scoop up waste from tricky spots, saving you countless hours with a wheelbarrow.

To make things clearer, here’s a quick rundown of how the most common options stack up against each other.

| Disposal Method | Best For | Typical Cost | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| Skip Hire | Ongoing projects with mixed waste; allows for gradual filling. | £120 – £400+ | Cost-effective for volume; keeps waste contained on-site. | Requires space; may need a permit if placed on a public road. |

| Man and Van | Quick, single clearances; when you need help with labour. | £50 – £250+ | Labour is included; fast removal; ideal for bulky items. | Can be more expensive for larger volumes; less flexible for ongoing jobs. |

| Grab Lorry Hire | Large volumes of heavy, inert waste (soil, rubble); awkward access. | £250 – £500+ | No manual loading needed; large capacity; can collect from difficult spots. | Requires significant access for the lorry; not suitable for mixed waste. |

Each method has its place. A skip gives you time to fill it as you go, while a grab lorry is an instant, heavy-duty solution. Weighing up your specific needs will always lead to the smartest choice.

Key Questions for Your Waste Provider

No matter which service you land on, a bit of homework is essential for good waste management in construction. To make sure you’re partnering with a company that’s professional and fully compliant, you should always ask these questions:

- Are you a registered waste carrier? Don't be shy – ask for their licence number and check it.

- What happens to my waste? A reputable company will be proud of their recycling process and can tell you their diversion-from-landfill rates.

- Are there any hidden costs? Get everything in writing. Confirm prices for permits, delivery, collection, and any potential charges for excess weight.

- What materials are prohibited? Every company has a list of no-gos. Make sure you know what you can and can’t get rid of.

- What is your collection timeframe? Know how quickly they can deliver a skip or collect a full one. The last thing you want is a full container holding up your project.

Getting this sorted from the start means your waste is handled legally, efficiently, and with zero disruption to your work.

The Future of Construction Waste Management

The way we handle construction waste is on the cusp of a major shake-up. We're moving away from the simple "chuck it out" mindset towards a much smarter, more connected approach. This change is being powered by new technologies, fresh thinking, and tighter rules, all pushing the industry to be more sustainable and efficient.

For contractors and developers, getting ahead of these trends isn't just good practice anymore—it's what gives you a real edge over the competition. The future of waste management in construction isn't about finding bigger landfills; it's about designing waste out of the picture right from the start.

Embracing the Circular Economy

One of the biggest ideas shaping our future is the circular economy. It's a total flip from the old "take, make, dispose" model. Instead, it treats every material as a valuable asset that should never become waste in the first place. It's a fundamental change in how we think.

Imagine a building planned not just for its immediate use, but for the day it will eventually be taken down. Materials are chosen because they can be easily disassembled, recovered, and slotted into new projects. This means everything from steel beams to internal fittings can have a second, third, or even fourth life, slashing the need for new resources and the amount of rubbish we produce.

The circular economy challenges us to see every material on site as being in a continuous loop of use and reuse. It’s about closing the loop, turning potential waste back into a valuable resource, and building a truly sustainable construction industry.

The Rise of Digital Tools and Prefabrication

Technology is what makes this vision possible. Digital tools like Building Information Modelling (BIM) are completely changing how projects are designed. BIM creates a super-detailed 3D digital version of a building, letting architects and builders spot potential waste hotspots before a single spade ever hits the ground.

By running a simulation of the whole build, teams can fine-tune material orders, coordinate how components are made, and cut down on off-cuts with incredible precision. This digital-first planning goes hand-in-hand with the growth of prefabrication and modular construction, where parts are built in controlled factory settings, slashing on-site waste even further. Putting these ideas into practice is the first step towards better construction site waste segregation and resource control.

Evolving Regulations and Smarter Cities

New laws are also giving the industry a much-needed push. The UK waste management market, valued at USD 8.32 billion in 2023 and expected to reach USD 12.50 billion by 2030, is seeing some big regulatory shifts. Fresh Extended Producer Responsibility (EPR) rules are starting to move the cost and hassle of waste away from local councils and onto the developers and manufacturers who create it. This gives them a powerful incentive to design for recyclability right from day one.

At the same time, smart city projects are bringing in tech like IoT sensors and AI to create more efficient waste collections and boost material recovery. This data-driven approach promises a future where waste management isn't just reactive but predictive and perfectly optimised. Getting on board with these changes is key to building a profitable and resilient business.

Turning Waste Management into a Business Asset

Smart waste management in construction is about so much more than just ticking boxes to stay compliant. It's where environmental responsibility and savvy business sense meet. By starting to see every off-cut, leftover brick, and bit of surplus material as a potential asset instead of a liability, you can unlock some serious financial and green credentials.

This change in mindset is everything. Instead of viewing waste disposal as just another cost tacked onto the end of a job, the best contractors treat it as a crucial performance metric to be tracked and improved from day one. It’s all about designing waste out of the project from the start, not just dealing with the pile-up in the skip later on.

The core idea is simple but incredibly powerful. If you stick to the principles of the waste hierarchy, you’ve got a clear roadmap to a more efficient, profitable project.

A Final Look at the Core Principles

Let's do a quick recap of the framework that underpins all good waste management:

- Reduce: This is your number one goal. Careful planning, ordering materials precisely, and using prefabricated elements where possible stops waste from even being created. This is where you'll find the biggest cost savings, hands down.

- Reuse: Before anything gets tossed, you’ve got to ask if it can have a second life. Can that timber be used for bracing elsewhere? Can those old fixtures or hardcore be repurposed on-site? Doing this cuts your procurement and disposal costs in one go.

- Recycle: For whatever's left, proper segregation is vital. Separating out your metals, wood, plasterboard, and inert waste makes sure they can be reprocessed effectively, keeping them out of expensive landfill.

These aren't just fluffy concepts; they are real, practical actions you can take on-site. Truly understanding the role of waste management in sustainable construction projects is key to building a modern, competitive business that looks after both its bottom line and the planet.

The big takeaway here is that you're in control. Stop seeing waste as an unavoidable problem and start treating it as a resource waiting to be managed properly. Every single tonne of material you divert from landfill is a direct win for your budget and your company's reputation.

Your challenge now is to put this knowledge into practice. Don't feel like you have to change everything overnight. Just commit to trying one new strategy from this guide on your very next project. Whether it’s getting better at segregating materials, trying a new supplier with a take-back scheme, or just spending an extra hour on your initial material estimates, small changes build real momentum. That single step is your starting point for a more profitable and sustainable future.

Frequently Asked Questions

Even with the best plan in the world, questions always pop up on-site. Getting fast, clear answers to common construction waste queries can save you a world of pain – not to mention time and money. Here are a few of the ones we hear most often from both seasoned contractors and first-time homeowners.

What Is a Waste Transfer Note and Why Is It So Important?

Think of a Waste Transfer Note (WTN) as the official passport for your rubbish. It’s a legal document that tracks every load of waste from the moment it leaves your site to its final destination. More importantly, it's your proof that you’ve done your bit correctly by handing the waste over to a licensed carrier – fulfilling your 'Duty of Care'.

Without a properly filled-out WTN, you have zero evidence of what happened to your waste. If it gets fly-tipped down a country lane, the authorities could trace it back to you, and you’ll be the one facing hefty fines. You must hold on to your copies for at least two years.

Can I Put Plasterboard in a Mixed Skip?

In a word: no. You absolutely cannot mix plasterboard with other waste. When plasterboard and other gypsum-based materials get buried in a landfill with general rubbish, they start to decompose and can release hydrogen sulphide – a toxic, foul-smelling gas.

Because of this, plasterboard disposal is very tightly regulated. It has to be kept separate, either in its own dedicated skip or in special plasterboard sacks. If you don't segregate it, you risk having your entire load rejected at the tip, or being hit with expensive contamination charges.

Bottom line: Always keep plasterboard completely separate from everything else. This isn't just a 'nice-to-do' for good site management; it's a non-negotiable legal rule to protect people and the environment.

What’s the Difference Between Inert and Non-Inert Waste?

Getting your head around this is key to sorting your waste properly and keeping your disposal costs down. The names might sound a bit technical, but the idea is actually quite simple.

- Inert Waste: This is the stuff that doesn’t rot or react. We’re talking about soil, rubble, bricks, concrete, and sand. It's usually heavy, but it’s also easy to recycle into new aggregates.

- Non-Inert Waste: This covers everything else that can break down or react. Materials like wood, plastics, paper, cardboard, and any green waste from clearing the site fall into this category.

Keeping these two streams apart is a game-changer for your budget. A clean load of soil and rubble is cheap to process because it has real recycling value. A mixed skip, on the other hand, needs a lot of sorting, which costs more. A bit of separation on-site directly saves you money.

How Can I Reduce My Project’s Disposal Costs?

The single best way to slash your disposal bill is to follow the waste hierarchy we talked about earlier. Simply put, the less you throw away, the less you have to pay. It starts with cutting down waste at the source – order materials accurately to avoid off-cuts and plan carefully.

Next, get creative with reuse. Can that timber be salvaged? Can those old bricks be cleaned up for a new feature? Finally, get serious about segregation on-site. Using separate, clearly marked skips for things like inert waste, metal, and wood will always work out cheaper than chucking it all into one big mixed skip. It takes a little more thought up front, but the savings really do add up.

At The Waste Group, we take the hassle out of responsible and cost-effective waste management. Whether you need help choosing the right skip or want peace of mind on legal compliance, our team is here to help your project run smoothly. Get a fast, competitive quote for your waste solutions at https://www.thewastegroup.co.uk.