What Is MOT Type 1 Your Guide to Sub-Base Aggregate

What Is MOT Type 1 Your Guide to Sub-Base Aggregate

When you’re planning a new driveway, patio, or path, it’s easy to focus on the final look – the stylish block paving or the sleek tarmac finish. But the real secret to a project that lasts for years without sinking, shifting, or cracking lies hidden beneath the surface.

Think of it like building a house. You wouldn't build on soft ground without a solid concrete foundation, would you? It’s the same principle for any paved surface. You need a tough, stable sub-base to handle the weight and pressure, and that's exactly where MOT Type 1 comes in.

Your Project's Foundation Explained

This material is the unsung hero of countless construction and landscaping jobs across the UK. It provides the strong, invisible backbone that ensures your investment stands the test of time, whatever you throw at it.

What Makes It The Go-To Choice?

So, what exactly is MOT Type 1? It’s not just a pile of rubble. This is a precisely engineered crushed aggregate, originally specified by the old Ministry of Transport (which is where the 'MOT' name comes from). Today, it must meet the strict standards laid out in Clause 803 of the Specification for Highway Works (SHW).

It's usually made from tough, durable rock like granite or limestone. But the real magic is in the mix.

MOT Type 1 is a carefully graded blend of different-sized particles, from hefty 40mm chunks right down to fine dust. When this mixture is laid and compacted, the pieces lock together like a 3D jigsaw puzzle, creating an incredibly dense and stable layer.

The larger stones provide the bulk and strength, while the smaller particles and dust fill in all the gaps. This process, known as mechanical interlock, is what gives the sub-base its exceptional load-bearing strength. It spreads the weight evenly and prevents any movement.

This simple but effective principle ensures your new driveway can handle the weight of a car day in and day out, and your patio won't develop dips and wobbles after a few seasons.

To get a quick overview of its key features, take a look at the table below.

MOT Type 1 At a Glance

| Characteristic | Description |

|---|---|

| Material Type | Crushed aggregate (e.g., granite, limestone) |

| Particle Sizes | Graded from 40mm down to dust |

| Key Property | Excellent load-bearing capacity and compaction |

| Governing Spec | Clause 803 of the Specification for Highway Works |

| Common Uses | Sub-bases for roads, driveways, patios, paths |

| Main Function | To create a stable, solid, and level foundation |

This combination of strength, reliability, and strict quality control is why MOT Type 1 remains the industry standard for sub-bases.

If you’re planning a project that needs a solid footing, feel free to explore our full range of high-quality aggregates to find the perfect materials for the job.

Understanding The Makeup Of MOT Type 1

To really get what MOT Type 1 is all about, you have to look past the pile of stones and see it as a properly engineered product. Its incredible strength doesn’t just come from the type of rock used; it’s the result of a precise recipe of different-sized particles all working together. We call this concept grading.

Imagine trying to build a solid, sturdy wall using nothing but perfectly round marbles. You'd end up with loads of gaps, creating a weak and wobbly structure that you could easily push over. MOT Type 1 is the exact opposite of that.

It's made from angular, crushed stone—not smooth, rounded gravel. These sharp, jagged edges are absolutely vital because they allow the pieces to lock and grip onto each other when compacted.

The Secret Is In The Mix

The specific grading of MOT Type 1 is what truly sets it apart. The material is a carefully controlled mixture of aggregate sizes, typically ranging from chunky 40mm pieces right down to fine particles, often just called ‘fines’ or dust. And that's no accident; it’s completely by design.

When you lay and compact the material, something quite clever happens:

- The large stones (40mm) create the main structural backbone, providing the bulk of the strength.

- The medium-sized stones naturally fall into the gaps between the larger pieces, filling up the major voids.

- The fine particles and dust then work their way down into the tiniest remaining spaces, locking everything together tightly.

This process creates an exceptionally dense layer with very few air pockets, almost like a complicated 3D jigsaw puzzle. The final result is a sub-base with fantastic load-bearing capabilities, ready to support whatever you decide to build on top of it.

MOT Type 1’s well-graded nature is its defining feature. The combination of coarse and fine aggregates allows for maximum compaction, creating a stable, interlocking layer that resists movement and settlement over time. This is why it’s specified for everything from highways to domestic driveways.

Meeting The Official Standard

This specific recipe isn't just a casual suggestion; it's a strict, official requirement. For any aggregate to be certified as genuine MOT Type 1, it must comply with Clause 803 of the Specification for Highway Works (SHW). This is the government standard in the UK that lays out the exact grading curve and physical properties the material must have.

This certification is your guarantee of quality. It means the aggregate has been properly tested to ensure it has the correct particle size distribution, is resistant to frost, and possesses the strength needed to create a durable, long-lasting sub-base. Using uncertified material is a huge gamble that can easily lead to project failure down the line.

When you choose a certified MOT Type 1, you're investing in a product that has been engineered for performance and longevity.

Where You’ll Typically Find MOT Type 1

MOT Type 1 is one of the real workhorses of the construction and landscaping world, and for good reason. Thanks to its incredible strength and knack for creating a solid, stable base, it’s the go-to aggregate for pretty much any project that needs to handle heavy loads and stand the test of time.

You'll find it everywhere, from huge civil engineering jobs right down to simple garden makeovers. It provides that reliable backbone you need for a professional, long-lasting finish. Let's look at where it shines.

The Ultimate Sub-Base for Driveways

This is probably the most common use for MOT Type 1, and it’s easy to see why. Your driveway has to put up with the weight of a car—often weighing over a tonne—day in and day out. Without a proper sub-base, any tarmac or block paving will quickly start to sink, rut, and look a mess under that constant pressure.

Laying a properly compacted layer of MOT Type 1 creates a solid platform that spreads the vehicle's weight out evenly. This simple step is what stops the ground from settling and keeps your driveway smooth and level for years. It’s the non-negotiable first step for a durable, professional-looking entrance to your home.

Creating Perfect Patios and Garden Paths

It's the same story for patios and paths. They need a stable foundation to stop paving slabs from shifting, sinking, or turning into a trip hazard. The classic UK freeze-thaw cycle can make the ground heave and move, but a well-compacted MOT Type 1 sub-base stands firm against these forces.

It gives you a firm, level bed to lay your slabs or decorative stones on, making sure they stay exactly where you put them. This is the secret to a neat, long-lasting finish that you won’t have to keep patching up. For some great ideas on creating a beautiful and functional walkway, have a look at our guide to creating a self-binding gravel pathway.

Think of MOT Type 1 as an investment in your project's future. It's the difference between a patio that looks good for one summer and one that remains a solid, enjoyable part of your garden for decades.

Solid Foundations for Garden Buildings

Garden sheds, summerhouses, and home offices are popping up in gardens everywhere, but they all need a solid base to sit on. Just putting one straight onto soft ground is a recipe for disaster. The structure will inevitably sink unevenly, causing doors to jam and potentially twisting the whole frame.

A simple but highly effective solution is to lay and compact an MOT Type 1 base. This gives you a perfectly level and incredibly strong platform that can easily handle the weight of the building and everything inside it. It’s a far more robust and permanent solution than just chucking a few loose slabs down.

Getting to grips with materials like MOT Type 1 is key to any robust landscaping project. For some broader insights into foundational materials, it's worth exploring the benefits of using gravel in landscape design.

How to Properly Install MOT Type 1

Getting a professional, long-lasting finish isn't just about using the right stuff; it's all about how you install it. Properly laying and compacting your MOT Type 1 sub-base is what creates that solid, unmoving foundation your entire project depends on. Nail this stage, and you've got a driveway that'll last for decades. Get it wrong, and you could see it failing within a few years.

Think of it like making the perfect espresso. You can have the best coffee beans in the world, but if you don't tamp them down with just the right pressure, you'll end up with a weak, watery shot. It’s exactly the same principle here – proper compaction is everything.

Preparing The Ground

Before you even think about tipping the aggregate in, your first job is to prep the area. This means digging out the ground to the correct depth to accommodate both your sub-base and whatever final surface you're putting on top. For a typical driveway, you’re usually looking at a sub-base depth of around 150mm.

Once you've excavated, it’s vital to compact the soil at the very bottom of the trench (this is known as the subgrade). After that, lay down a geotextile membrane. This fabric sheet is a game-changer: it stops your MOT Type 1 from sinking and mixing into the soil below, and it also helps prevent pesky weeds from growing through.

Laying and Compacting in Lifts

This is the most critical part of the whole process. Whatever you do, don't be tempted to dump all your MOT Type 1 in one go and try to compact it in a single thick layer. It just won't work. The force from the compactor won't reach the bottom, leaving you with a weak and unstable base that’s bound to shift.

The right way to do it is to lay the aggregate in layers, or ‘lifts’ as they’re known in the trade.

-

Spread the First Layer: Add your first layer of MOT Type 1, making sure it’s no deeper than 100mm-150mm. Rake it out so it’s reasonably level across the whole area.

-

Compact Thoroughly: Grab a wacker plate (a vibrating plate compactor) and go over the entire surface multiple times. You’ll actually see the aggregate settle down and lock itself into place.

-

Repeat as Needed: Add your next layer, again keeping it no deeper than 150mm, and repeat the whole compaction process. Keep going until you reach the final depth you need.

A really common mistake is trying to compact a layer that's way too deep. Stick to a maximum of 150mm per lift to make sure every single particle, from the top right down to the bottom, is fully interlocked and stable. This careful process is what guarantees a truly solid foundation.

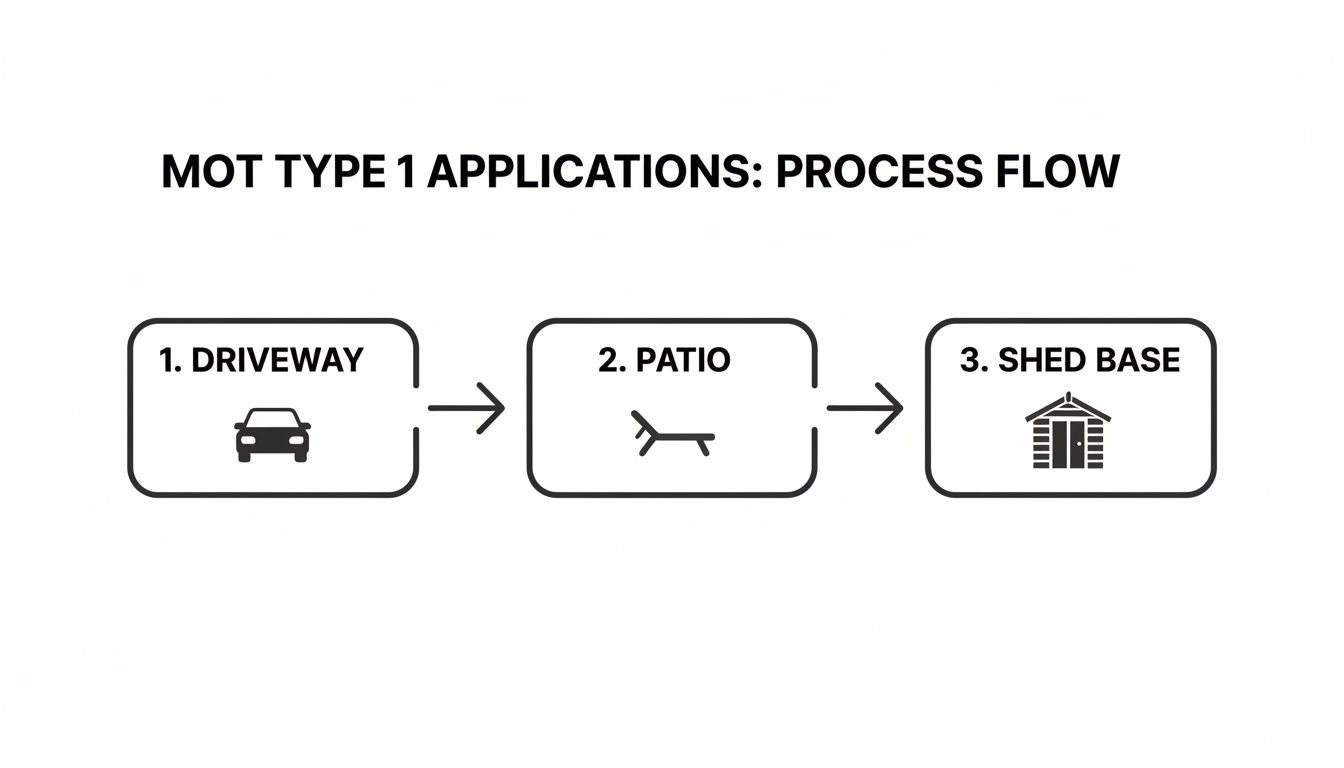

This visual guide shows a few of the most popular projects where this kind of robust foundation is absolutely essential.

As the diagram shows, a single, reliable installation method provides the backbone for driveways, patios, and shed bases alike. By following these steps, you create a solid platform that ensures your final surface—whether that’s paving slabs, tarmac, or a shed floor—remains perfectly level and secure for years to come.

Calculating How Much MOT Type 1 You Need

One of the first questions on any project is always the same: "How much stuff do I actually need to order?"

It's a classic problem. Order too little, and you're stuck with frustrating delays and extra delivery charges. Order too much, and you’ve wasted money on material that's just going to sit there taking up space. Luckily, figuring out your MOT Type 1 needs is pretty straightforward once you know how.

This process takes the guesswork out of the equation. It means you can budget properly and get just the right amount to do the job properly the first time. It all boils down to a simple volume calculation.

The Basic Formula for Volume

First things first, you need to work out the volume of the area you’re planning to fill. This is measured in cubic metres (m³). The formula is a simple multiplication of the three dimensions of your space.

The Calculation: Length (metres) x Width (metres) x Depth (metres) = Volume (m³)

Just be sure to convert all your measurements into metres before you multiply them. For instance, if you need a sub-base with a depth of 150mm, you’ll use 0.15m in your calculation. It’s a small step, but it’s crucial for getting an accurate result. The principles are much the same for other materials, as you can see in our guide on calculating concrete volume.

Converting Volume to Tonnes

MOT Type 1, like nearly all aggregates, isn't sold by volume – it's sold by weight, specifically in tonnes. This means you need to do one last conversion: turning your cubic metre figure into a tonnage. To do that, we need to know the material's bulk density.

As a solid rule of thumb, one cubic metre of compacted MOT Type 1 weighs about 2 tonnes.

So, the final piece of the puzzle is simple:

- Volume (m³) x 2 = Required Tonnes

For example, if you worked out that you need 4m³ of aggregate for your project, you'd need to order 8 tonnes (4 x 2). This simple conversion makes sure the right amount arrives on site.

A Quick Reference Guide

To make things even easier, here’s a quick-glance table for some of the most common projects where you'd be using MOT Type 1.

MOT Type 1 Quantity Guide for Common Projects

| Project Type | Area (Example) | Recommended Depth | Estimated Tonnes Needed |

|---|---|---|---|

| Garden Path | 10m x 1m | 100mm (0.10m) | 2 Tonnes |

| Patio Sub-base | 5m x 4m | 150mm (0.15m) | 6 Tonnes |

| Single Driveway | 10m x 3m | 150mm (0.15m) | 9 Tonnes |

| Shed Base | 3m x 2m | 100mm (0.10m) | 1.2 Tonnes |

Remember, these are just estimates to give you a starting point. Always measure your specific area for the most accurate figures!

Getting the depth right is absolutely critical for the long-term success of your project. For example, a driveway that's 10m long by 5m wide, with a proper 150mm depth, needs 7.5m³ of material, which is 15 tonnes. It's tempting to skimp, but industry data from 2022 revealed that a shocking 25% of UK driveway failures were caused by sub-bases that weren't deep enough, leading to expensive repairs down the line.

Your MOT Type 1 Questions Answered

Even the most straightforward project can throw up a few last-minute questions. To make sure you're starting on solid ground, we've pulled together the queries we hear most often about MOT Type 1. This should clear up any final uncertainties you might have.

What's The Difference Between MOT Type 1 And Type 3?

It all boils down to one simple thing: drainage.

MOT Type 1 is blended for brute strength. The mix includes fine dust that packs down tight, filling all the little gaps to create an incredibly dense, solid layer. The downside to this is that water can’t get through it very quickly.

MOT Type 3, on the other hand, is made with far fewer of these fine particles. This leaves more tiny spaces between the stones, allowing water to drain through with ease. That's why it's the go-to for permeable paving systems that need to be SUDS-compliant (Sustainable Urban Drainage Systems).

For most everyday projects like driveways, patios, and building bases where you need maximum stability, Type 1 is still the king.

Can I Just Use Gravel Instead of MOT Type 1?

This is a really common question, but using standard gravel or ballast as a substitute is a false economy and a mistake we strongly advise against. These materials just aren't designed for the heavy-lifting job of a sub-base.

Regular gravel often has rounded edges, and ballast is a mix of sand and stone made for mixing concrete, not for creating foundations. Neither has the sharp, angular stones of MOT Type 1 that are essential for locking together under pressure.

Using the wrong aggregate is a shortcut you'll pay for later. Your paving or driveway will almost certainly shift, sink, or fail much sooner than it should, leaving you with a costly repair job. MOT Type 1 is specified for this load-bearing role for a very good reason.

Do I Really Need A Geotextile Membrane Underneath?

Yes, you absolutely do. While it might look like an optional extra you can skip, laying a geotextile membrane is one of those small steps that makes a massive difference to the lifespan and sturdiness of your project.

You simply roll this tough fabric out over the soil before putting down your MOT Type 1. It does two vital jobs at once:

- Separation: It stops your expensive aggregate from slowly getting pushed down and mixed into the soil below, which weakens the whole structure.

- Weed Control: It forms a powerful barrier that stops pesky weeds and roots from forcing their way up through your lovely new surface.

It's a cheap and easy part of the job that pays for itself many times over in the long-term quality of your work.

Ready to build a foundation that lasts? At The Waste Group, we supply and deliver high-quality, certified MOT Type 1 aggregate across Dorset. Get a competitive quote and fast, reliable service by visiting us at https://www.thewastegroup.co.uk.