A Practical Guide to Your Construction Waste Management Plan | The Waste Group

A Practical Guide to Your Construction Waste Management Plan | The Waste Group

A construction waste management plan is a formal document that maps out how you'll identify, minimise, segregate, and dispose of waste materials on a project. Think of it as a proactive strategy for controlling costs, staying on the right side of the law, and shrinking your project's environmental footprint. It’s about moving waste management from an afterthought to a core part of your project planning from day one.

Why Your Project Needs a Waste Management Plan

Treating a construction waste management plan as just another piece of paperwork is a costly mistake. In reality, it's a powerful tool for boosting project efficiency, profitability, and your company's reputation.

Ignoring it is a direct path to inflated landfill taxes, project delays from cluttered and unsafe sites, and some serious compliance headaches. The real value of a good plan lies in its ability to turn waste from a liability into a properly managed resource.

The scale of this issue is immense. The UK’s construction sector is responsible for around 62% of all waste produced annually, which works out to about 100 million tonnes. This staggering figure comes from construction, demolition, and excavation work.

While the industry does a great job of recovering over 90% of this material (often for use as aggregate), the sheer volume highlights why meticulous planning is non-negotiable for every single project.

From Cost Centre to Profit Driver

A well-executed plan does more than just keep your site tidy; it has a direct, positive impact on your bottom line.

Picture this: on a mid-sized commercial build, the project manager implemented a simple waste segregation strategy right from the start. By separating clean hardcore, timber, and metals from the general waste skips, the project dodged the highest landfill tax rates completely.

This simple, proactive step resulted in a documented saving of over £15,000 in disposal fees alone. That's before you even factor in the revenue generated from selling the high-value scrap metal, which would have otherwise been lost in a mixed-waste skip.

This scenario tells a simple truth: every tonne of waste you send to landfill is a financial drain. A solid plan helps you plug that drain through a few key actions:

- Accurate Material Ordering: The best way to reduce waste is to not create it in the first place. Preventing over-ordering is your first line of defence.

- On-Site Reuse: You can often identify materials like crushed concrete or hardcore that can be repurposed right there on-site, cutting both disposal and new material procurement costs.

- Effective Segregation: Separating recyclables ensures they are processed at a much lower cost than sending everything off as general mixed waste.

Beyond the Financials: The Broader Impact

The benefits stretch far beyond just saving money. A clean, well-organised site is fundamentally a safer site, reducing trip hazards and improving the overall workflow for everyone involved.

What's more, showing a real commitment to responsible waste management significantly boosts your company's reputation with clients, regulators, and the local community. Understanding the full environmental impact of construction waste often provides that extra motivation to get your processes dialled in.

Ultimately, a construction waste management plan isn’t about ticking boxes for compliance; it’s about running smarter, safer, and more profitable projects.

Getting to Grips with UK Waste Management Laws

Let's be honest, navigating the legal side of construction waste can feel like a minefield. But it’s a non-negotiable part of any project in the UK. Getting it wrong isn't just a slap on the wrist; it can lead to hefty fines and even prosecution. At the heart of it all is your legal 'duty of care'.

This duty of care, laid out in the Environmental Protection Act 1990, means you are legally on the hook for your waste from the moment you create it until it’s properly disposed of. You can't just pass the buck. Even after a skip company has collected your waste, if they end up fly-tipping it or handling it incorrectly, the responsibility can still land back at your door.

So, what does fulfilling this duty actually involve? It means taking all reasonable steps to make sure your waste is managed by the book. This boils down to a few key actions:

- Stop illegal handling: You have to make sure no unauthorised person gets their hands on your waste.

- Use licensed carriers: Only ever give your waste to a carrier who is officially registered. Don't be shy—always ask to see their waste carrier's licence.

- Complete a waste transfer note (WTN): This is the crucial bit of paperwork that acts as a legal record of the waste changing hands. It details what the waste is, how much there is, and who is taking it away.

The Role of Waste Transfer Notes

Think of a waste transfer note as a passport for your rubbish. A WTN must be filled out and signed by both you and the waste carrier for every single load of waste that leaves your site. This document is your golden ticket for proving you've done everything right.

Imagine you’re doing a small home renovation that fills a skip with mixed timber and plasterboard. When the skip company shows up, you need to make sure the WTN accurately lists these materials. This is absolutely vital because certain materials, like plasterboard, need special handling and can't just be chucked into a landfill with general waste. An accurate WTN ensures it goes down the right disposal route.

Key Takeaway: You must keep copies of all your waste transfer notes for at least two years. If the Environment Agency ever comes knocking, these documents are your primary evidence that you’ve met your duty of care obligations.

Are Site Waste Management Plans Legally Required?

This is a common point of confusion. A few years back, Site Waste Management Plans (SWMPs) were mandatory in England for any project over a certain value. That specific legal requirement has since been scrapped.

However, don't let that fool you into thinking your responsibilities have lessened. While there's no longer an explicit law demanding a formal SWMP, these plans are still the best tool you have for managing your waste properly. An SWMP, sometimes called a Resource Management Plan, is seen as the industry gold standard for showing how you’re meeting your duty of care.

Frankly, trying to prove you're compliant without one is a much tougher job. You can find out more about how these plans help ensure compliance and environmental stewardship from this construction waste guide.

Building Your Construction Waste Management Plan

A good construction waste management plan isn't something you just fill out and file away. It’s a practical, working document that needs strategic thinking before the first shovel even hits the ground. Think of it as a blueprint for handling your waste responsibly, starting with a detailed understanding of what your project will actually produce.

The whole process kicks off with a pre-construction waste audit. This is more than a quick glance; it’s a systematic review of your project plans and specs to forecast the types and volumes of waste you’ll be dealing with. For a small housing development, you'd be looking at major streams like concrete from the foundation work, timber offcuts from framing, plasterboard, and huge amounts of packaging.

Once you’ve got that forecast, you can move beyond vague hopes and start setting some tangible targets.

Setting Realistic Targets and Roles

With a handle on your likely waste streams, you can set specific, measurable goals. Forget generic targets like "recycle more." A powerful, actionable goal sounds like this: "Divert 95% of hardcore and clean concrete from landfill by crushing on-site for use as sub-base." See the difference? That goal has a clear action and a definite, measurable outcome.

Just as important is assigning clear roles. A plan without someone in charge is just a piece of paper. You need to nominate a ‘Waste Champion’ on-site—this is often the site manager or a dedicated supervisor who is responsible for seeing the plan through.

Their day-to-day duties would include:

- Briefing all subcontractors on the waste segregation strategy during their site induction.

- Making sure waste stations are clearly labelled and, crucially, used correctly.

- Managing all the necessary paperwork, like waste transfer notes.

This creates a clear line of accountability and ensures someone is actively driving the plan forward every single day.

From Procurement to Disposal: A Practical Walkthrough

Let’s go back to our small housing development scenario. A solid plan would map out the entire lifecycle of your key materials. It starts with smart material ordering—things like ordering pre-cut timber frames or specific lengths of pipework can drastically slash the amount of on-site cutting and, therefore, the offcuts you produce.

Next up is the on-site logistics. Where will you put the segregated skips for wood, metal, and general waste so they’re easy for everyone to access but don't get in the way of site traffic? Nailing your construction site waste segregation is fundamental. Get it wrong, and you end up with costly cross-contamination of valuable recyclables.

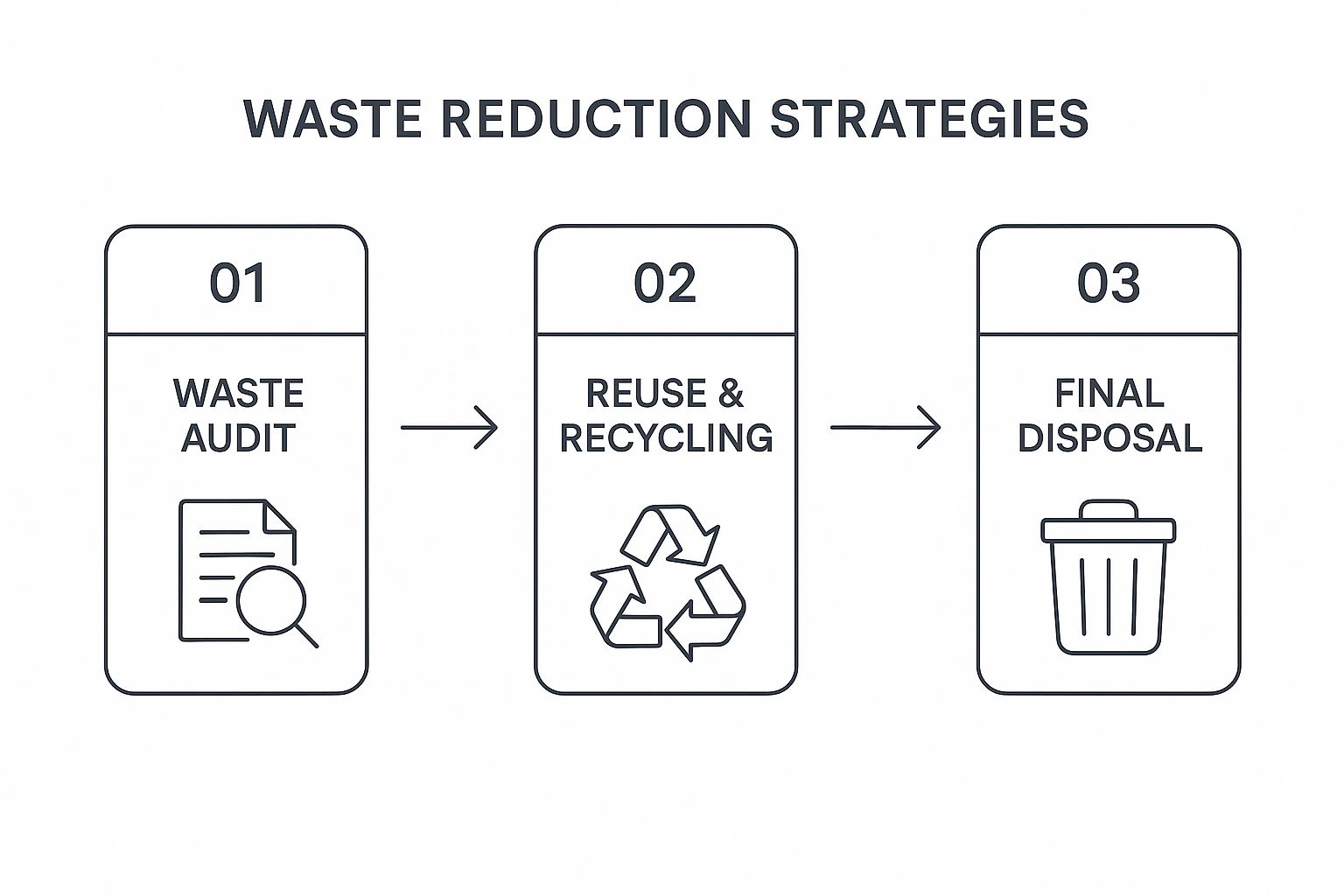

The infographic below shows the basic workflow of a well-structured waste reduction strategy.

As you can see, a successful plan is a continuous loop. It starts with a thorough audit and ends with responsible disposal, with reuse and recycling sitting right at its heart.

Finally, your plan must detail the final disposal routes for everything. This means finding and vetting licensed waste carriers and recycling facilities for each specific waste stream you’ll generate. For our housing development, that means finding a local facility that takes plasterboard for recycling, a scrap merchant for metals, and a licensed tip for the small amount of non-recyclable general waste.

Expert Tip: Get to know your waste contractors early on. Talk to them about your project’s specific waste streams and what you’re trying to achieve. A good partner can give you invaluable advice on the best skip sizes and collection schedules, helping you avoid paying for half-empty lifts or last-minute emergency call-outs.

By breaking the process down into these chunks—audit, targets, roles, and logistics—your waste management plan becomes a dynamic, practical tool. It’s an adaptable blueprint that transforms waste from an inevitable headache into a managed resource, saving you money and seriously boosting your project's green credentials.

A detailed construction waste management plan looks great on paper, but its real worth is only proven out on site. That transition from a document to daily practice is exactly where a lot of well-intentioned strategies fall apart. It's rarely a lack of trying, but more often a failure to make the right choice the easy choice for every single person on the project.

Success really boils down to your on-site setup. The waste segregation station can't be an afterthought, stuffed into some forgotten corner of the site. It needs to be central, impossible to miss, and simple for anyone to use. Let's be honest, if it's easier for a chippy to toss a timber offcut into the general waste skip five feet away than walk twenty feet to the wood skip, you know where it’s going to end up.

Setting Up for Success

The easiest way to stop expensive cross-contamination is with clear, direct communication. There's a reason colour-coded skips are the industry standard—they’re an instant visual guide. But you can't stop there. You absolutely must back them up with large, weatherproof signs that use simple language, and even better, pictures, to show what goes where.

Your signs need to be crystal clear.

- What goes in: A timber skip sign, for example, shouldn't just say "Wood." It needs to specify "Clean Timber Only," "No Painted or Treated Wood," and "Remove all plastic wrapping."

- What stays out: The same sign should be just as clear about what's not allowed: "No Plasterboard," "No Plastic," and "No General Rubbish."

This removes any guesswork. It gives your team the confidence to make the right call every time, which is essential for protecting the value of your recyclable materials.

A classic mistake is assuming everyone knows the difference between waste streams. Just one sheet of plasterboard in a general waste skip can contaminate the entire load. That means it gets rejected at the recycling facility, re-classified, and you end up paying the higher landfill tax on the lot. Simple, direct instructions prevent these expensive blunders.

Fostering Team Buy-In and Monitoring

Your plan is dead in the water without buy-in from everyone on-site, from the general labourers right through to your specialist subcontractors. This is where toolbox talks are worth their weight in gold.

Use these quick daily or weekly meetings to keep the waste management goals front and centre. Show the team the progress you're making, explain why the rules matter (it saves the project money, it helps us hit our environmental targets), and sort out any confusion on the spot.

Good monitoring doesn't have to be a massive chore. In fact, simple, consistent checks are far more effective than a massive audit every few weeks. Appoint your on-site waste champion to do a quick visual inspection of the skips every day. This way, you spot contamination issues early and can give immediate, constructive feedback to the teams involved.

Alongside the visual checks, a simple digital log is a powerful ally. Use it to keep track of every waste transfer note, log when skips are collected, and record the weights of different materials leaving the site. This data is not just for proving you're compliant; it's invaluable information that will help you fine-tune your plans for the next project. As technology evolves, consider how new approaches like drone use in construction can give you a bird's-eye view of your site, helping with progress tracking and overall monitoring.

Measuring Success and Refining Your Strategy

The job isn’t quite over when the project is complete and the site is cleared. The final, and arguably one of the most important, parts of your construction waste management plan is about to kick in. This is where you measure what actually happened against what you planned.

So, how do you know if all your efforts paid off? The answer is sitting in your on-site logs and waste transfer notes. This paperwork isn't just about ticking compliance boxes; it's a goldmine of data that shows you exactly what worked and where you can improve next time.

Key Performance Indicators to Track

Your post-project analysis should focus on a few critical metrics. These give you a clear, objective view of your plan’s performance and highlight where you can make improvements.

- Waste Diversion Rate: This is the big one. It’s the percentage of total waste that you successfully kept out of landfill through recycling or reuse. A good target to aim for is anything above 90%, which is a common industry benchmark.

- Cost Savings: It's time to tally up the disposal costs. Compare the lower fees for segregated recyclables against the much higher costs of sending general waste to landfill. The difference is your total savings from avoiding landfill tax.

- Contamination Levels: How often were your segregated skips contaminated with the wrong materials? If it happened a lot, it’s a clear sign you need better on-site training or clearer signage on your next project.

This data-driven approach is proving effective on a national scale. In 2022, England generated 63.0 million tonnes of non-hazardous construction and demolition waste. Thanks to better management practices, the recovery rate climbed to an impressive 94.3%, meaning almost 59.4 million tonnes were kept out of landfill.

Turning Insights into Action

Analysing this data helps you pinpoint what worked well and what didn't. Did your plasterboard segregation strategy succeed? If you want to refine your approach, have a look at our detailed guide on how to dispose of plasterboard correctly.

Perhaps you found that timber offcuts were a much bigger waste stream than you anticipated. This insight might prompt you to explore pre-fabrication options for the next build to minimise cuts on-site.

By treating the end of each project as a learning opportunity, you create a cycle of efficiency. The insights from one job directly inform and strengthen the waste management plan for the next, making your operations progressively leaner, cheaper, and more sustainable. This refinement is what separates a good plan from a great one.

Your Top Waste Management Questions Answered

Even with the best-laid plans, questions are bound to pop up on-site. Getting these common queries sorted clears up any confusion and helps make sure everyone on the team is implementing the waste plan properly. Let's dig into some of the most frequent questions we hear from project managers and site supervisors.

What’s The Most Important Part Of a Construction Waste Plan?

Honestly, it all starts with the initial waste audit. This is the bedrock of your entire strategy.

Accurately forecasting the types and amounts of waste your project is going to generate allows you to do everything else effectively. You can set realistic reduction targets, order the right size and type of skips, and, crucially, budget properly for disposal costs.

Without that initial data-driven step, you're essentially just guessing. And that's a fast track to inefficient segregation, ordering the wrong skips, and getting hit with surprise costs when a waste stream turns out to be much bigger than you anticipated.

How Do I Get The Site Team To Actually Follow The Waste Plan?

Getting the team on board is everything. You need to combine clear communication with making it incredibly easy for them to do the right thing. It’s a two-pronged attack that boils down to clarity and convenience.

- Make it mandatory: Kick things off with a compulsory toolbox talk during the site induction. This is your chance to explain the plan and, most importantly, the "why" behind it – whether that's hitting environmental targets or saving the project serious money.

- Make it obvious: Use big, clear, weatherproof, and colour-coded signs on every single waste container. A picture or a bold colour is much quicker for a busy person to process than text alone.

- Make it accountable: Appoint a ‘waste champion’ on-site. Having a designated person to oversee the process and answer questions makes a massive difference in keeping things on track.

When the site leadership team visibly takes waste management seriously, everyone else follows suit. It transforms it from just another chore into a shared responsibility for the whole project.

Can a Good Waste Management Plan Genuinely Save Us Money?

Absolutely. The savings come from a few different places and are often much bigger than project managers first realise.

Your biggest win comes from slashing your landfill tax bill. This tax is charged by weight and is at its highest for mixed, unsorted general waste. Segregated materials like metal, clean wood, and hardcore are significantly cheaper to get rid of.

Beyond that, a smart plan actively looks for chances to reuse materials on-site. Think crushing old concrete to use as a sub-base, which cuts down your material procurement costs. Finally, planning properly means you avoid paying for half-empty skips or getting stung with emergency collection fees when a container overflows unexpectedly.

At The Waste Group, we provide reliable and fully compliant waste management solutions to help your construction project run smoothly. From straightforward skip hire to comprehensive commercial waste services, we make managing your site waste simple. Find out how we can support your next project.