How to Recycle Plasterboard: A Practical Guide

How to Recycle Plasterboard: A Practical Guide

Recycling plasterboard isn't just a sustainable choice; in the UK, it's a legal requirement and a matter of safety. You absolutely cannot send gypsum-based materials to a standard landfill, and for a very good reason. When it gets mixed up with all the other waste, it decomposes and lets off toxic hydrogen sulphide gas.

Knowing how to recycle plasterboard is a must-have piece of knowledge for any construction project or home renovation.

Why Recycling Plasterboard Is Not Optional

It catches a lot of people off guard when they learn they can't just chuck old plasterboard into a skip with everything else. This isn't just a friendly suggestion from green campaigners; it's a legal mandate from the Environment Agency. The problem all comes down to its main ingredient, gypsum, and what happens to it in a landfill.

When gypsum gets wet and mixes with biodegradable waste – think paper, leftover food, or wood offcuts – it creates the perfect breeding ground for sulphate-reducing bacteria. These tiny organisms break down the gypsum and, in the process, release hydrogen sulphide (H₂S), a colourless, highly toxic gas famous for its lovely "rotten egg" smell.

The Dangers of Hydrogen Sulphide

The creation of this gas is no joke and poses some serious risks. Even in small amounts, hydrogen sulphide can irritate your eyes, nose, and throat. At higher concentrations, it can lead to severe respiratory issues, and in an enclosed space, it can be fatal.

This is exactly why landfill operators are legally bound to keep gypsum-based waste in its own separate, dedicated cells, well away from any other materials.

But the immediate safety hazards aren't the only problem. Disposing of it this way has wider environmental impacts.

- Air Pollution: H₂S pollutes the air and can become a huge nuisance for communities living anywhere near landfill sites.

- Contamination: Leachate (the liquid that drains from a landfill) from decomposing plasterboard can contaminate groundwater and soil, creating long-term ecological headaches.

- Wasted Resources: Simply throwing plasterboard away means we're wasting valuable gypsum. It's a perfectly recyclable resource that can be turned back into new products.

The Scale of the Problem

The UK construction industry produces a staggering amount of plasterboard waste every year. It’s estimated that hundreds of thousands of tonnes are still ending up in landfill. This isn't just a massive missed opportunity to recover a useful material; it also puts a huge strain on our already limited landfill space.

Moving to a system where recycling is the default option is a huge part of building a more sustainable future. Understanding the ideas behind a circular economy in waste management really highlights why these rules are so important.

By properly separating and recycling your plasterboard, you're not just staying on the right side of the law – you're actively protecting the environment and helping create a safer, more resource-savvy industry.

Getting Your Plasterboard Ready for Recycling

Successful recycling starts on-site, long before any waste ever leaves your project. How you handle the plasterboard from the get-go is the single biggest factor in whether it can be turned into a new product or ends up being rejected at the gate. The main goal is simple: deliver clean, uncontaminated gypsum waste to the recycling facility.

Think of it like cooking. If you throw the wrong ingredients into the pot, you’ll ruin the final dish. It’s exactly the same with plasterboard. Contamination from other building materials can make the entire load completely useless for the recycling machinery.

Set Up a Dedicated Segregation Area

Whether you're running a massive construction site or just tackling a small home renovation, your first move should be to create a specific, clearly marked area just for plasterboard waste. This simple step prevents it from getting mixed up with all the other rubbish. It could be a designated corner of a room, a covered spot in the garden, or a dedicated skip bag.

On a professional site, this means briefing your team and making sure everyone understands why keeping gypsum separate is so important. For a weekend DIY job, it’s about getting into good habits right from the start. If you're dealing with major repairs or a big renovation, you might even bring in a professional, like a local drywall repair contractor, who can manage the removal and segregation of the old boards efficiently.

Just creating a separate pile is a massive step. It also ties back to why you can’t put plasterboard in skips with general waste — it all comes down to the contamination and legal headaches we’ve talked about.

https://www.thewastegroup.co.uk/news/why-cant-you-put-plasterboard-in-skips/

Remove All Contaminants Before Collection

Once it’s separated, the plasterboard itself needs to be ‘cleaned’ of anything that isn’t plasterboard. The machinery at recycling plants is designed to process gypsum and its paper lining, but not much else. Before you start stacking your offcuts, take a moment to methodically pull off any non-gypsum attachments.

Here are the usual suspects you need to look out for:

- Metal Fixings: Screws, nails, and metal corner beads all have to come out.

- Tiles and Adhesives: Any ceramic tiles and the gunk holding them on need to be scraped off.

- Wood and Studs: Remove any bits of timber framing or skirting boards still attached.

- Insulation: Foam or foil-backed insulation must be stripped away from the board.

- Wallpaper: A single layer of standard wallpaper is usually okay, but thick vinyl or woodchip papers should be removed if you can.

A good rule of thumb is: if it isn't gypsum or the paper liner it came with, it needs to go. Taking ten minutes on-site to pull screws and strip away tiles can be the difference between a successful recycling run and a rejected load.

Keep It Dry at All Costs

Water is the absolute enemy of plasterboard recycling. Once gypsum gets wet, it turns into a useless sludge that clogs up machinery and is impossible to process. For any recycling facility, this is a complete non-starter.

You must always store your separated plasterboard under cover. Use a tarpaulin, stick it in the garage, or use a skip bag that has a lid. If your plasterboard waste gets soaked by rain, it will almost certainly be turned away by the recycler. That leaves you with a pile of waste that’s much more difficult and expensive to get rid of. Keeping it dry ensures all your hard work doesn’t go to waste.

Choosing the Right Plasterboard Collection Method

Once you've got your plasterboard sorted, clean, and dry, the next logistical hurdle is getting it from your site to a recycling plant. The best way to do this really comes down to the scale of your project, where you have to weigh up cost against pure convenience. There's a solid option for everything, from a small DIY bathroom refresh to a massive commercial build.

Getting this part right is crucial. It ensures all your hard work sorting the material doesn't go to waste and keeps you on the right side of the regulations.

Dedicated Skip Bags for Smaller Projects

For a lot of homeowners and small trade jobs, dedicated plasterboard skip bags are the perfect solution. You'll typically find them as one-tonne bags that you can buy, fill up in your own time, and then just call a specialist company to come and collect them when you're ready.

The biggest plus here is flexibility. You can keep the bag on-site for as long as you need, filling it as you go without the ticking clock of a standard skip hire.

- Best For: Small renovations, single-room clear-outs, and jobs where space is tight.

- Cost: You pay for the bag itself and then a separate collection fee. For smaller volumes, this can be a really cost-effective way to do things.

- Convenience: They're a godsend for tight spots like driveways where a traditional metal skip just wouldn't fit.

Specialist Waste Management Services

When you're dealing with a serious amount of plasterboard from a big renovation or a construction site, a specialist waste management service is easily the most practical choice. These companies provide dedicated skips or even huge roll-on-roll-off bins specifically for plasterboard waste.

This approach really simplifies the whole process. The provider drops off the container, you fill it with your clean plasterboard, and they handle the rest – transport, recycling, and providing you with the all-important Waste Transfer Note. It's often worth looking into companies that offer general construction services, as many will have integrated waste management solutions.

Using a certified service gives you complete peace of mind that your waste is being handled legally. It removes all the guesswork, guaranteeing your plasterboard actually reaches a proper recycling centre instead of being dumped illegally.

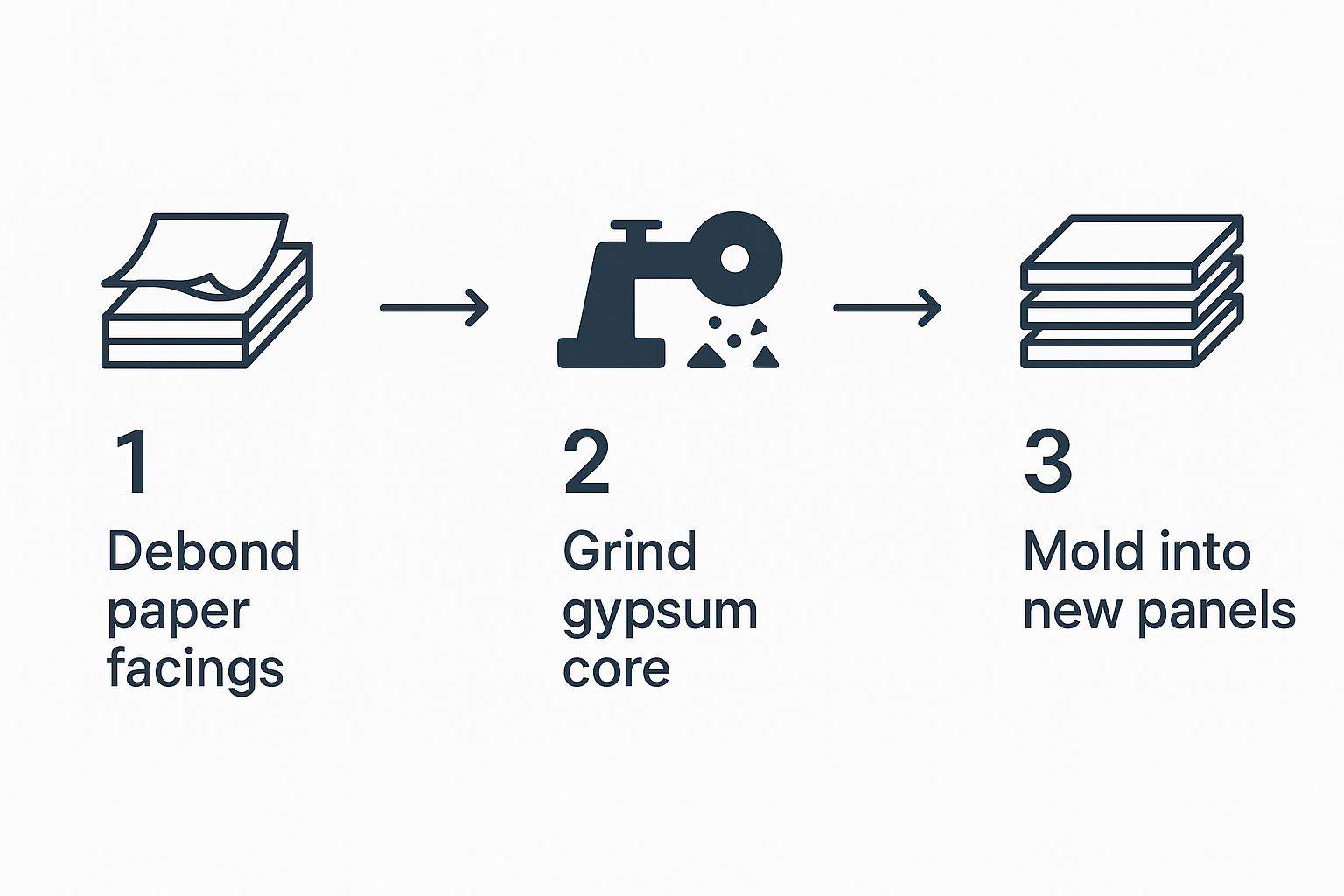

This graphic breaks down the journey your plasterboard takes after it leaves your site.

As you can see, it's all about recovering that clean gypsum by stripping away the paper and grinding down the core, getting it ready to become brand new plasterboard.

Using Local Council Recycling Centres

If you've only got a tiny amount of plasterboard, maybe a few offcuts from a single board, your local Household Waste Recycling Centre (HWRC) is often your best bet. Most council-run tips now have designated containers just for gypsum materials.

You absolutely must check your local council's rules before you load up the car, though. Many have strict limits on how much you can bring in, and they almost never accept commercial waste.

The UK's recycling infrastructure is still playing catch-up. As a country, we generate around 3.0 million tonnes of plasterboard waste every single year. The shocking part? A huge chunk of that, an estimated 1 million tonnes, still ends up in landfill. We've got a long way to go.

Where Your Plasterboard Goes: A Look Inside UK Recycling

So, you've done the hard work of separating your plasterboard, keeping it clean, and getting it collected. But what happens next? It doesn't just disappear. Instead, it starts an impressive journey through a specialist industrial process that transforms construction waste back into a valuable resource, right here in the UK.

This isn't your local scrapyard. The journey from your site to a new product is handled by highly controlled facilities packed with advanced tech. Their sole purpose? To recover pure gypsum from waste boards and get it back into the supply chain.

Inside the Recycling Plant

Once a lorryload of plasterboard waste arrives, it’s put through a slick, multi-stage mechanical process. The main goal is to cleanly separate the gypsum core from its paper lining. It’s a bit like trying to peel the label off a thousand tiny jars all at once.

Here’s a rough idea of how it works:

- Shredding: First up, powerful industrial shredders break the boards down into smaller, more manageable chunks.

- Separation: A clever combination of screens, blowers, and vibrating conveyors then gets to work, stripping the paper away from the gypsum fragments.

- Grinding: Finally, the clean gypsum is milled down into a fine powder, all set for its next life.

This process is incredibly efficient, recovering over 95% of the gypsum. This is precisely why your efforts on-site to keep the boards free from tiles, screws, and insulation are so critical. Contaminants can easily damage the machinery and ruin the purity of the final gypsum powder.

A few dedicated companies are leading the charge in the UK. For instance, Plasterboard Recycling UK (PBR:UK) crunches through around 4,000 tonnes of plasterboard waste every month. Meanwhile, Roy Hatfield’s plant can process about 1,000 tonnes a week, ensuring none of their processed gypsum ever sees a landfill. You can dive deeper into these pioneering efforts in the UK plasterboard recycling market report.

From Waste to Raw Material

The recovered gypsum powder isn't just waste; it's a high-quality raw material with some brilliant end uses. The journey really comes full circle when it’s sold back to plasterboard manufacturers to create brand-new boards. This "closed-loop" system is the gold standard for recycling.

By recycling your plasterboard, you are directly contributing to a system where old building materials become the foundation for new ones. It reduces the need to mine for virgin gypsum, saves energy, and cuts down on carbon emissions.

But its story doesn't end there. Recycled gypsum has other surprising applications. Farmers can use it as a soil conditioner to improve drainage and give their crops a boost of calcium and sulphur. It’s also used in other industrial processes, like making cement. That old wall you tore down has a future you probably never imagined.

Staying Compliant with UK Plasterboard Waste Laws

Getting to grips with the legal side of waste disposal can feel a bit overwhelming, but when it comes to plasterboard, the rules are strict for a very good reason. Here in the UK, the Environment Agency has made it illegal to mix any gypsum-based materials with biodegradable waste in landfills. This isn't just bureaucratic red tape; it’s a crucial safety measure to stop the creation of highly toxic hydrogen sulphide gas.

Whether you're a DIYer tackling a single room or a site manager on a huge project, understanding your legal duties is non-negotiable. The fines for getting it wrong can be hefty, so it pays to do it right from the very start.

The All-Important Waste Transfer Note

For pretty much any project that's more than a small household job, you’re going to need a Waste Transfer Note (WTN). Think of it as a passport for your waste. It's a legal document that tracks the journey of your plasterboard from your site all the way to its final destination. More importantly, it's your proof that you've disposed of everything responsibly and in line with UK law.

Your WTN is the official record of the transfer, and you absolutely must keep a copy for at least two years. It needs to include a few key details:

- A clear description of the waste (e.g., "gypsum-based plasterboard waste").

- How much waste is being moved.

- The details of who produced the waste (that's you!) and who is collecting it.

- Confirmation that the waste hierarchy has been considered.

Failing to produce a valid WTN if the Environment Agency asks for it can lead to some pretty serious fines. It’s a simple bit of paperwork that gives you complete peace of mind.

Your Duty of Care as a Waste Producer

As the person or business creating the waste, you have what's known as a legal 'Duty of Care'. This basically means your responsibility doesn't just stop when the skip is driven away. You are accountable for ensuring that waste is handled correctly right through to its final recycling or disposal point.

This Duty of Care is exactly why choosing a licensed and reputable waste carrier is so critical. If you hand your plasterboard over to some unlicensed 'man-with-a-van' who then fly-tips it, you can still be held legally responsible. Always, always check for a valid waste carrier's licence.

Even though the UK generated a staggering 25.9 million tonnes of household waste in 2023, recycling materials like plasterboard still faces some real challenges. The big hurdles are a lack of infrastructure, high transport costs, and the fact that the material needs to be kept clean and dry to be recycled effectively. Take-back schemes have been around for a while, but getting them widely adopted is still a work in progress.

At the end of the day, staying compliant protects you legally and ensures your waste becomes part of a circular economy, not an environmental headache. It's also worth keeping an eye on broader Scottish Building Regulations, which can sometimes influence how waste is managed on site. For a more detailed guide, have a look at our article on how to dispose of plasterboard legally and responsibly.

Got Questions About Plasterboard Recycling? We’ve Got Answers.

Even when you’ve got the best intentions, a few practical questions always pop up once you start dealing with plasterboard waste. Getting the little details right makes the whole process smoother and, crucially, ensures all your effort doesn’t go to waste.

Here are the direct answers to the queries we hear most often, giving you a quick reference guide to handle your plasterboard recycling with confidence.

Can I Recycle Plasterboard with Wallpaper or Paint On It?

Yes, in most situations, you absolutely can. Modern recycling facilities are well-equipped to process plasterboard that’s been painted or has a standard layer of wallpaper attached.

The machinery they use is designed specifically to separate the paper lining from the gypsum core, and this process is pretty effective at removing these surface treatments at the same time. That said, this tolerance does have its limits.

You’ll need to remove thicker materials beforehand:

- Ceramic Tiles: These are a serious contaminant. They must be scraped off completely, along with any lingering adhesive.

- Thick Vinyl or Woodchip Papers: A single, thin layer of paper is fine, but any heavy-duty wall coverings should be stripped away first.

- Metal Fixings: Make sure all screws, nails, and metal corner beads have been removed.

It’s always a good idea to double-check with your chosen waste collector, as their specific equipment and capabilities can vary. A quick phone call can save you the headache of a rejected load.

What Happens If My Plasterboard Gets Wet?

Honestly, wet plasterboard is the biggest hurdle to successful recycling. The entire process relies on the material staying dry to work properly.

When plasterboard gets saturated with water, the gypsum core breaks down into a thick, sludgy paste. This gunk clogs up the specialised separation machinery, bringing the whole operation to a grinding halt. It also contaminates the final recycled gypsum product, making it completely useless.

It is absolutely vital to keep your segregated plasterboard covered and protected from the elements while it’s on-site. If it gets a proper soaking from the rain, it will almost certainly be rejected by the recycling facility and may have to be disposed of as specialist waste.

Is It Cheaper to Recycle Plasterboard Than to Send It to Landfill?

It might seem like the upfront collection fee for specialist recycling is higher at first glance, but it’s almost always the more cost-effective and legally compliant option in the long run.

Landfill tax on active waste is significant and keeps on rising. Because you’re legally forbidden from mixing gypsum with biodegradable waste, it requires its own costly, separate cell in a landfill. When you factor in these hidden costs and the very real potential for fines, recycling suddenly looks much more financially attractive.

For businesses, showing that you’re recycling properly also gives your environmental credentials a massive boost.

Can I Put Small Offcuts in My Household Recycling Bin?

No, you must never put plasterboard offcuts—no matter how small—into your standard kerbside recycling bin.

Plasterboard is classed as construction waste and is a major contaminant for household recycling streams. It will ruin the entire load of paper, plastic, and glass, forcing the council to send the whole lot to landfill instead.

For small amounts from a DIY project, your best bet is your local Household Waste Recycling Centre (HWRC). Many now provide dedicated bins just for plasterboard, but always check their website or give them a call to confirm they accept it before you make the trip.

At The Waste Group, we make responsible waste management straightforward. Whether you're handling a small home renovation or a large construction project, we provide compliant, reliable skip hire and collection services to ensure your plasterboard is recycled correctly. Get a quote online or contact our team today to find the perfect solution for your needs at https://www.thewastegroup.co.uk.